a layered mos 2 ‑tio 2 Preparation methods of nanocomposites

A nanocomposite material, mos2-tio2 technology, applied in the field of metal molybdenum, can solve the problems of poor photocatalysis and lubrication performance, unsuitable for industrial production, complex preparation process, etc., achieve high production efficiency, improve catalytic and lubrication performance, and operate simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

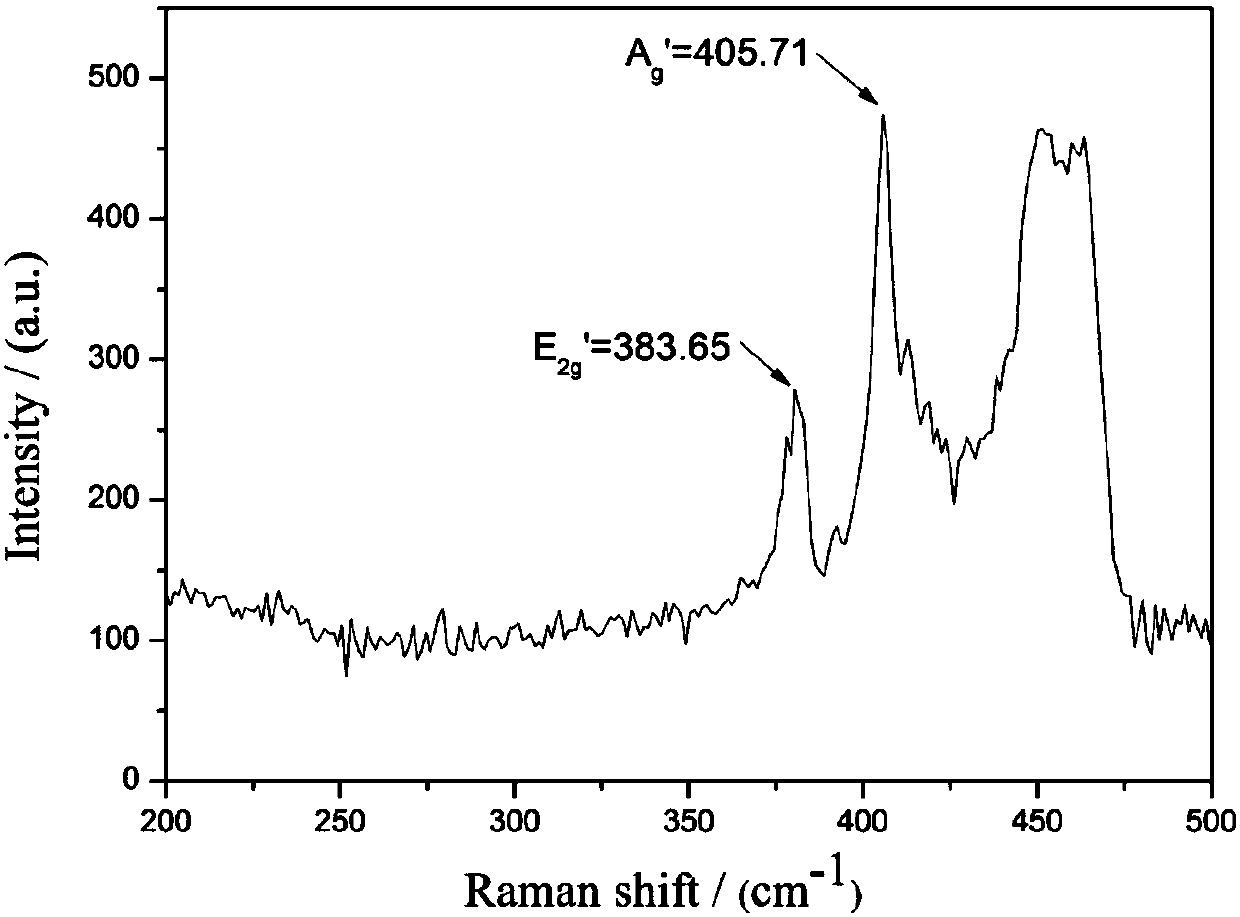

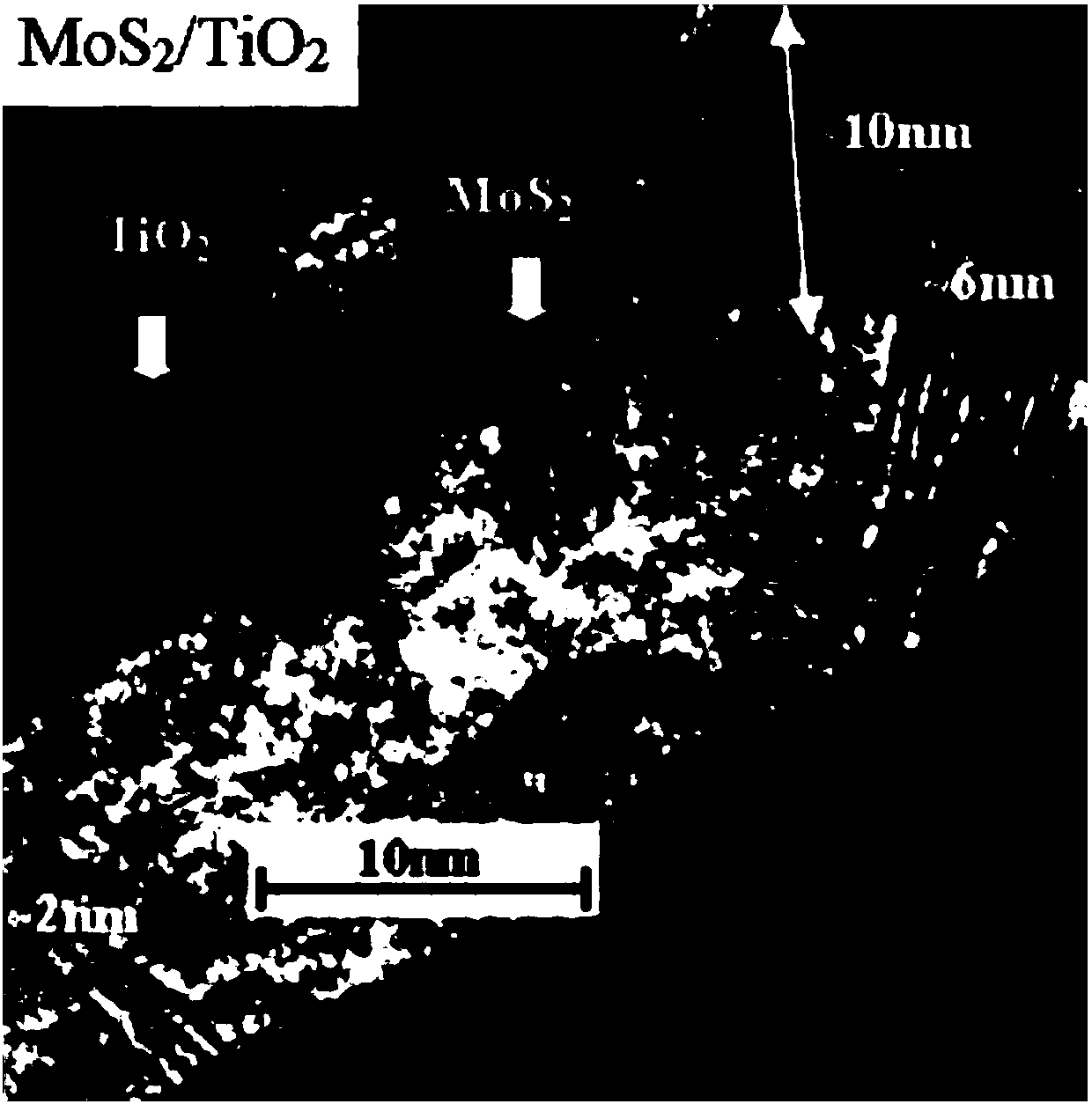

[0036] This example gives a layered MoS 2 -TiO 2 A method for preparing a nanocomposite material, the method specifically comprising the following steps:

[0037] Step 1: Take 10g of molybdenum disulfide powder and grind it to 200 mesh and sieve it, add it to an ethanol solution with a mass concentration of 10% and containing 100g of polyphenylene sulfide, heat it in a water bath to 30°C and stir for 12h to obtain a mixed solution.

[0038] Step 2, add 5g KMnO to the above mixed solution 4 powder, heated to 50°C in a water bath and stirred for 18 hours, filtered and dried the filter cake, ground to 200 mesh and sieved to obtain 3.3g of intercalated molybdenum disulfide powder.

[0039] Step 3, the gained intercalation molybdenum disulfide powder and 3.3gTiO 2 Nano-powder and 1.6g of picric acid are evenly mixed and put into a high-pressure reactor, vacuumized and argon is introduced, the reactor is heated to 500°C to explode, and after cooling to room temperature with the f...

Embodiment 2

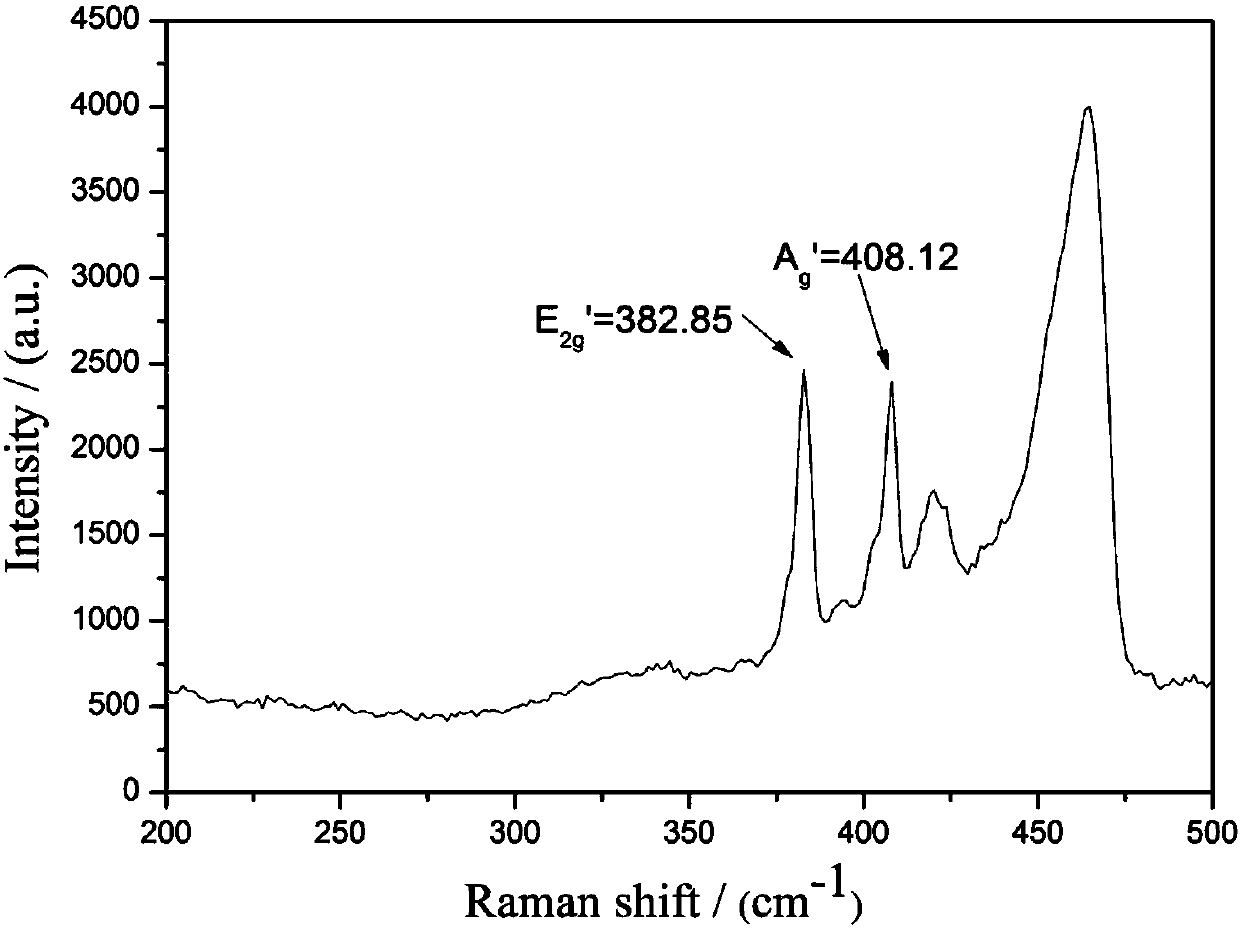

[0045] This example gives a layered MoS 2 -TiO 2 A method for preparing a nanocomposite material, the method specifically comprising the following steps:

[0046] Step 1: Grind 10 g of molybdenum disulfide powder to 200 mesh and sieve it, add it to an ethanol solution with a mass concentration of 20% and containing 200 g of polyphenylene sulfide, heat to 50° C. in a water bath and stir for 5 hours to obtain a mixed solution.

[0047] Step 2, add 10g KMnO to the above mixed solution 4 powder, heated to 80°C in a water bath and stirred for 8 hours, filtered and dried the filter cake, ground to 200 mesh and sieved to obtain 3g of intercalated molybdenum disulfide powder.

[0048] Step 3, the gained intercalation molybdenum disulfide powder and 1.5gTiO 2 Nano-powder and 3g of picric acid are evenly mixed and put into a high-pressure reactor, vacuumed and argon is introduced, and the reactor is heated to 480°C to explode, and after cooling to room temperature with the furnace, t...

Embodiment 3

[0051] This example gives a layered MoS 2 -TiO 2 A method for preparing a nanocomposite material, the method specifically comprising the following steps:

[0052] Step 1: Grind 10 g of molybdenum disulfide powder to a 200-mesh sieve, add it to an ethanol solution with a mass concentration of 30% and containing 300 g of polyphenylene sulfide, heat it in a water bath to 40° C. and stir for 8 hours to obtain a mixed solution.

[0053] Step 2, add 15g KMnO to the above mixed solution 4 powder, heated to 70°C in a water bath and stirred for 12 hours, filtered and dried the filter cake, ground to 200 mesh and sieved to obtain 2.8g of intercalated molybdenum disulfide powder.

[0054] Step three, the gained intercalation molybdenum disulfide powder and 0.8g TiO 2 Nano-powder and 5.6g of picric acid are evenly mixed into a high-pressure reactor, vacuumed and argon is introduced, and the reactor is heated to 450°C to explode. After cooling to room temperature with the furnace, the e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com