A device and method for disassembling and disassembling pivot sleeves of inlet valves in energy storage power stations

A technology of energy storage power station and pivot shaft, which is applied in the field of electric power, can solve problems that easily affect the maintenance period, affect the cold shrinkage of the shaft sleeve, and unfavorable shaft sleeve reinstallation, etc., so as to reduce the uncontrollable factors of maintenance, uniform force, and The effect of reducing the number of operators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The technical means adopted by the present invention to achieve the intended invention purpose are further described below in conjunction with the drawings and preferred embodiments of the present invention.

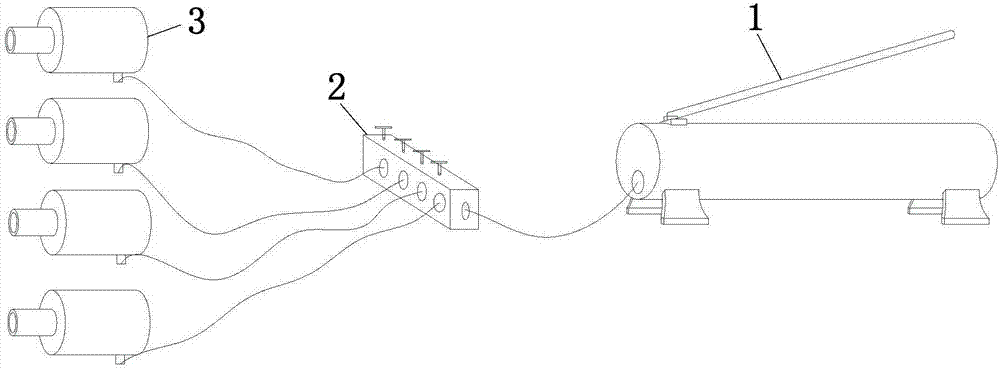

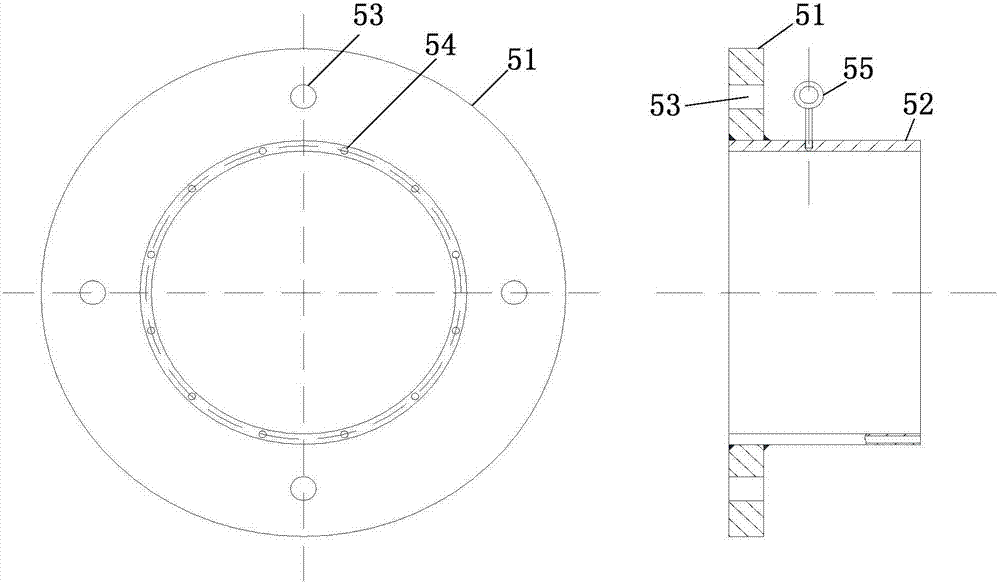

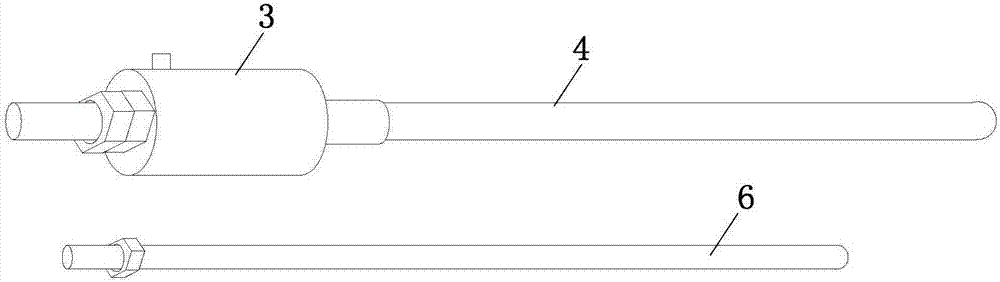

[0019] combine Figure 1 to Figure 3 As shown, the installation and disassembly device for the pivot bushing of the water inlet valve of the energy storage power station of the present invention includes: a hydraulic pump 1, a flow divider 2, a hollow jack 3, a stressed guide screw 4, a combined stressed set 5, and a bushing connecting screw 6 .

[0020] Further, such as figure 1 Shown is a schematic diagram of the structure of the force application part. The hydraulic pump 1 is connected to the flow divider 2, and the flow divider 2 is connected to the hollow jack 3. The hydraulic pump 1 is used to provide hydraulic power, and a manual hydraulic pump or an electric hydraulic pump can be used. If an electric hydraulic pump is used, the working efficiency will b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com