Method and apparatus for producing hydrochloric acid

A manufacturing method and technology for manufacturing devices, which are applied in separation methods, chemical instruments and methods, halogen/halogen acids, etc., can solve problems such as inability to remove iron ions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

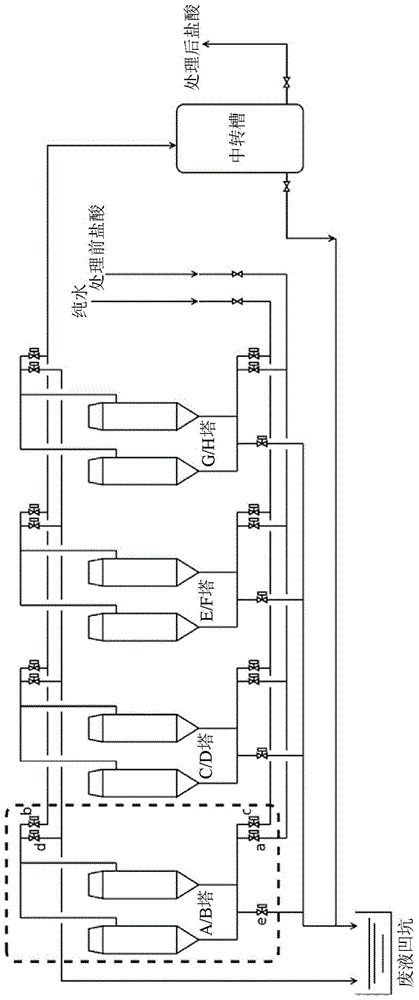

[0029] Using 4 series of refining columns with 2 columns and 1 group as 1 sequence arranged in parallel figure 1 In the shown device, while inserting the regeneration step of the ion exchange resin, the continuous treatment for removing iron ions from the crude hydrochloric acid extracted from the exhaust gas of the process is carried out.

[0030] It was assumed that crude hydrochloric acid was simultaneously supplied to three of the four trains to perform the iron ion removal step, and only the remaining one train was subjected to the resin regeneration step.

[0031] The resin regeneration step is to implement a series of treatments of a. Residual hydrochloric acid extraction → b. Pure water addition / extraction → c. Pure water continuous supply flow (200 minutes) / extraction. After the resin regeneration of one sequence is completed, crude hydrochloric acid is supplied to the sequence to start the iron ion removal step, the iron ion removal step of the next sequence is stopp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com