Dephosphorization agent and its preparation method and application

A phosphorus removal agent and red brick technology, applied in the field of construction waste resource utilization, can solve the problems of phosphorus removal agent biochemical system toxicity, high cost, limited phosphorus removal effect, etc., achieve environmental protection benefits, reduce treatment costs, excellent removal The effect of phosphorus effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] A kind of dephosphorization agent of the present invention, mainly with construction waste as raw material, is prepared by acid modification, high-temperature calcination activation and adding soluble sodium salt stirring, and construction waste is cement waste and red brick waste, and the temperature of high-temperature calcination activation is 900°C.

[0042] In this embodiment, the mass ratio of red brick dust to cement dust is 1:2.

[0043] A kind of preparation method of the phosphorus removal agent of above-mentioned present embodiment, comprises the following steps:

[0044] (1) Pretreatment of the base material: respectively air-dry the construction waste red brick waste and cement waste, grind them with a ball mill, and pass through a 200-mesh sieve to obtain red brick ash and cement ash.

[0045] (2) Batching: Red brick ash and cement ash are batched and mixed according to the mass ratio of 1:2 to obtain the material to be treated, that is, the mixed materia...

Embodiment 2

[0065] A preparation method of the phosphorus removal agent of the present invention is basically the same as that of Example 1, except that in step (4), the calcination temperature is 700° C. and the calcination time is 10 min.

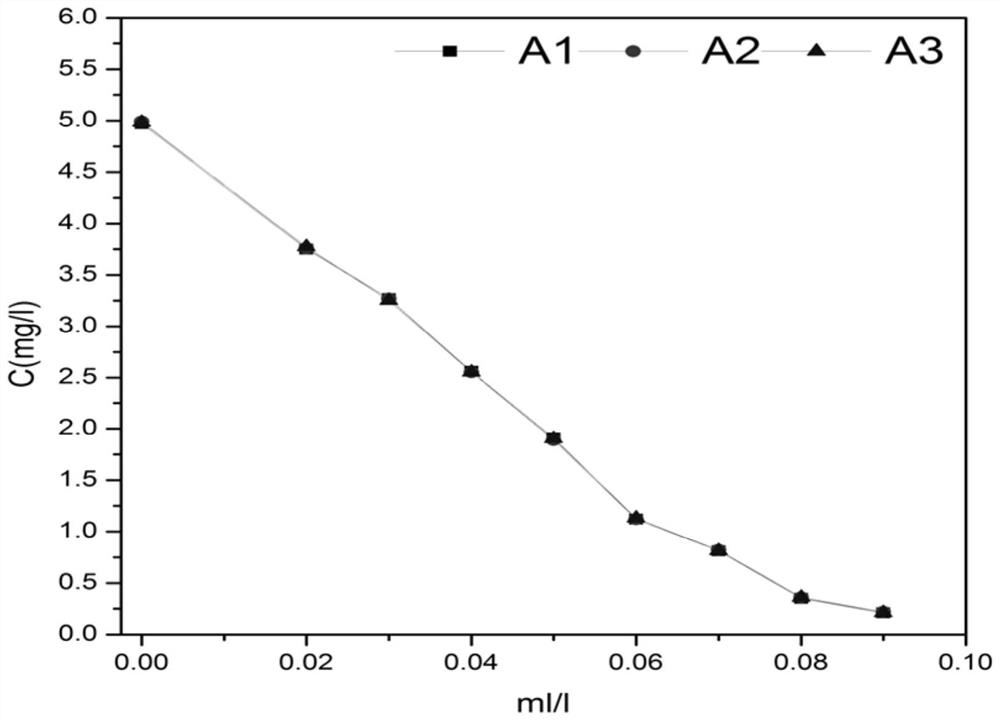

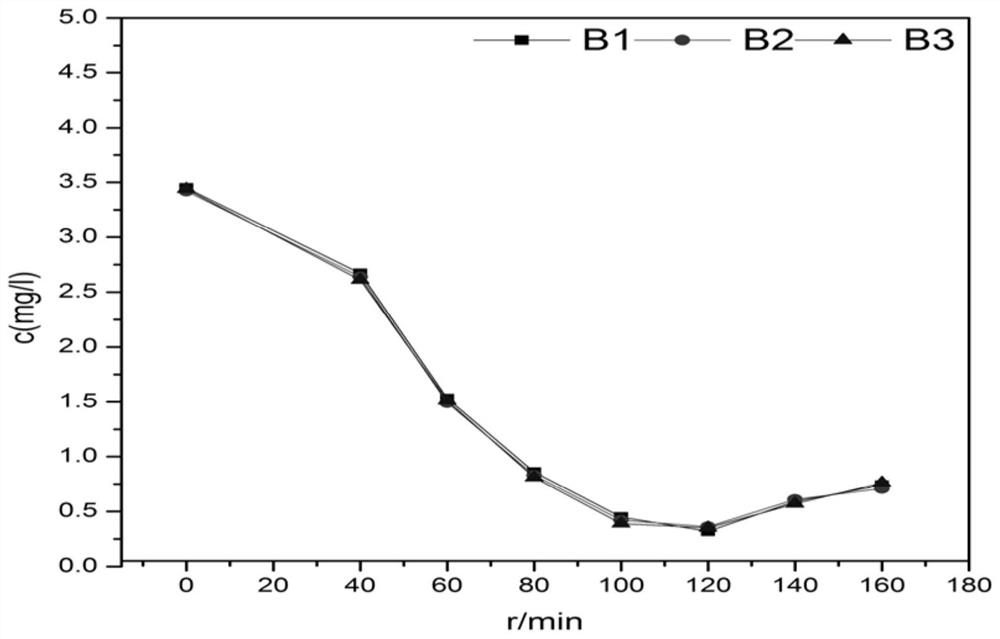

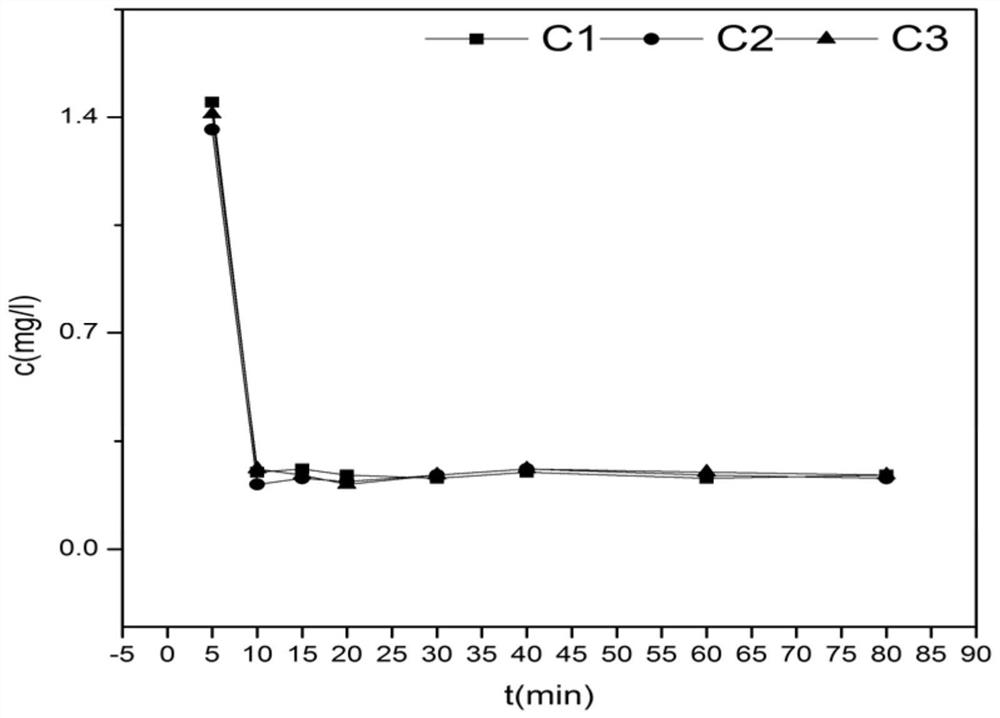

[0066] 0.08mL / L phosphorus removal agent prepared in this embodiment is dropped into 500mL with KH 2 PO 4 In the simulated phosphorus-containing wastewater with an initial phosphorus concentration of 5mg / L (in terms of P mass concentration), stir and react at a stirring rate of 120r / min for 10min at room temperature, add a flocculant to precipitate for 30min, and conduct phosphorus in the water. The phosphorus element in the treated water was detected, and the results showed that the phosphorus removal efficiency was 97.89%.

Embodiment 3

[0068] A preparation method of the dephosphorization agent of the present invention is basically the same as in Example 1, the only difference being: in step (1), the mass ratio of red brick ash and cement ash is 2: 1; in step (3), stirring The temperature was 108°C.

[0069] 0.08mL / L phosphorus removal agent prepared in this embodiment is dropped into 500mL with KH 2 PO 4 The configured initial phosphorus concentration is 5mg / L (in terms of P mass concentration) in the phosphorus-containing wastewater simulation liquid, stirred and reacted at a stirring rate of 120r / min at room temperature for 10 minutes, and added flocculant for precipitation for 30 minutes to remove phosphorus in the water body , the phosphorus element in the treated water was detected, and the results showed that the phosphorus removal efficiency was 99.25%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com