Method and device for electroadsorption-anammox treatment of inorganic ammonia nitrogen wastewater

An anaerobic ammonium oxidation and electro-adsorption technology, applied in aerobic and anaerobic process treatment, chemical instruments and methods, special compound water treatment, etc. Inorganic low ammonia nitrogen wastewater, easy operation and overcoming unstable operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

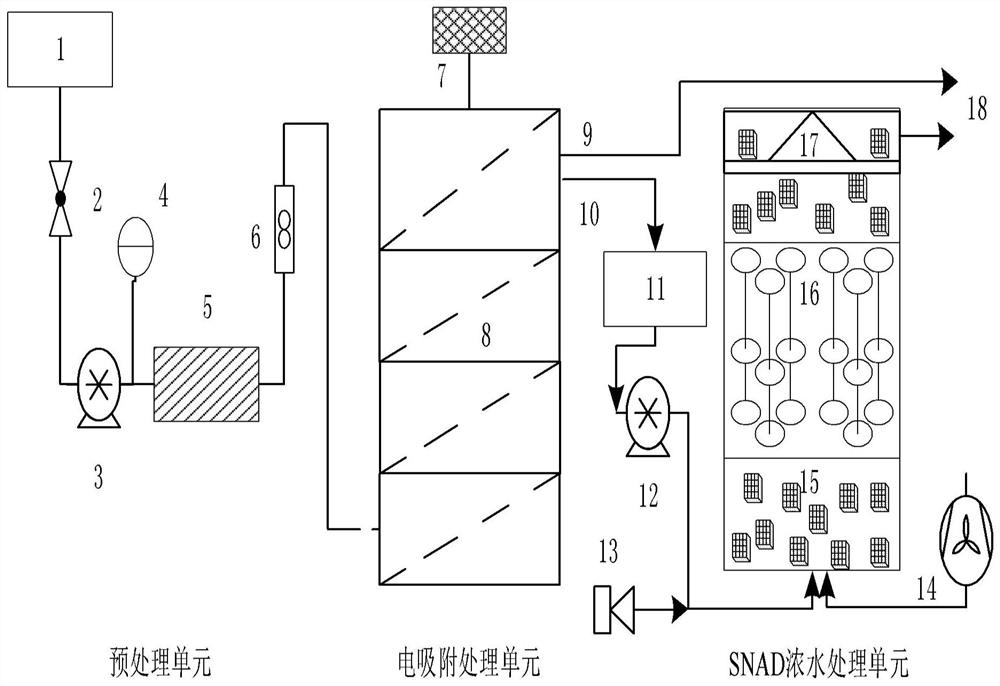

[0046] In the present embodiment, such as Figure 1 As shown, a kind of electrical adsorption - anaerobic ammonia oxidation treatment of inorganic ammonia nitrogen wastewater device, mainly by the pretreatment unit, electrosorption treatment unit, SNAD concentrated water treatment unit three parts, including inlet water tank 1, inlet valve 2, inlet water pump 3, pressure gauge 4, pretreatment reactor 5, flow meter 6, thyristor power supply 7, electrosorption reactor 8, electrosorption reactor water outlet 9, electrosorption reactor concentrated water outlet 10, intermediate pool 11, concentrated water inlet pump 12, carbon source dosing component 13, aeration pump 14, Sponge packing reaction assembly 15, combined packing reaction assembly 16, 1 sponge packing plus three-phase separator assembly 17, SNAD reactor outlet 18.

[0047] Among them, the inlet water tank 1 is connected to the pretreatment reactor 5 through the inlet pump 3, and is equipped with a pressure gauge 4 to detect...

Embodiment 2

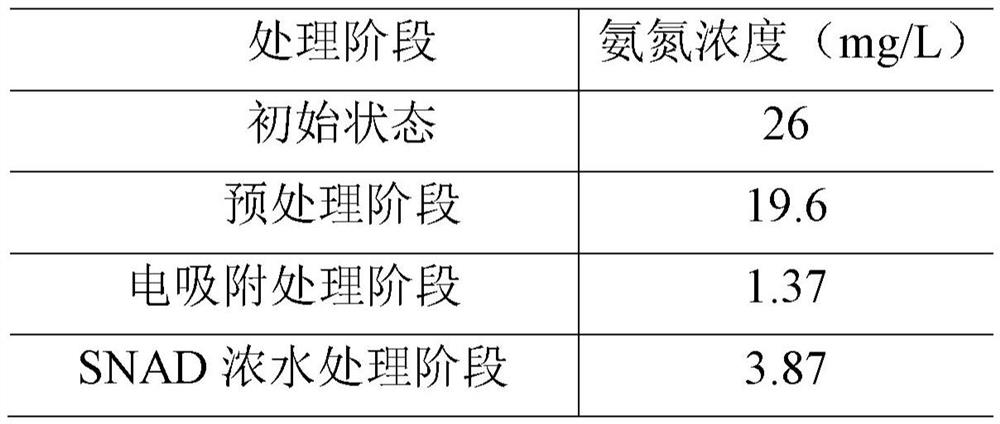

[0059] The apparatus and method of Example 1 were used to sample the chemical contaminated water source of a beijing plant to detect the ammonia nitrogen concentration of 26mg / L, and the low ammonia nitrogen wastewater was treated as follows:

[0060] Pretreatment unit: take 100L of wastewater that has been pretreated with high efficiency air flotation, and further remove the suspended solids and part of the organic matter of raw water into the quartz sand pretreatment reactor to ensure the normal operation of the subsequent electrosorption reactor treatment unit.

[0061]Electroadorption treatment unit: The pretreated raw water enters the electrosorption treatment unit, desalinates the raw water, and can further electrolyze the organic matter in the oxidized water, with a water yield of 72% and a desalination rate of 93%. When the output conductivity rises beyond the set upper limit, the PLC device automatically shorts the circuit, and the concentrated water generated by the raw ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com