Cordierite type microwave medium ceramic material and preparation method thereof

A technology of microwave dielectric ceramics and ceramic materials, applied in the field of electronic information functional ceramic materials and devices, can solve problems such as not many types

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

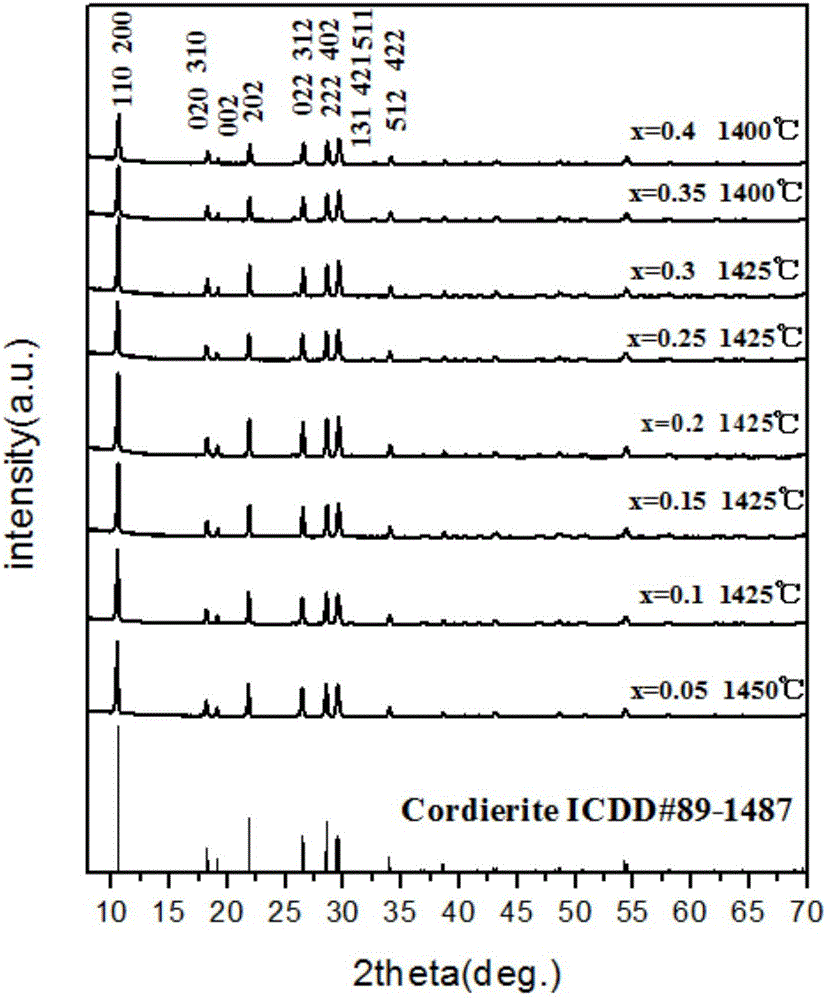

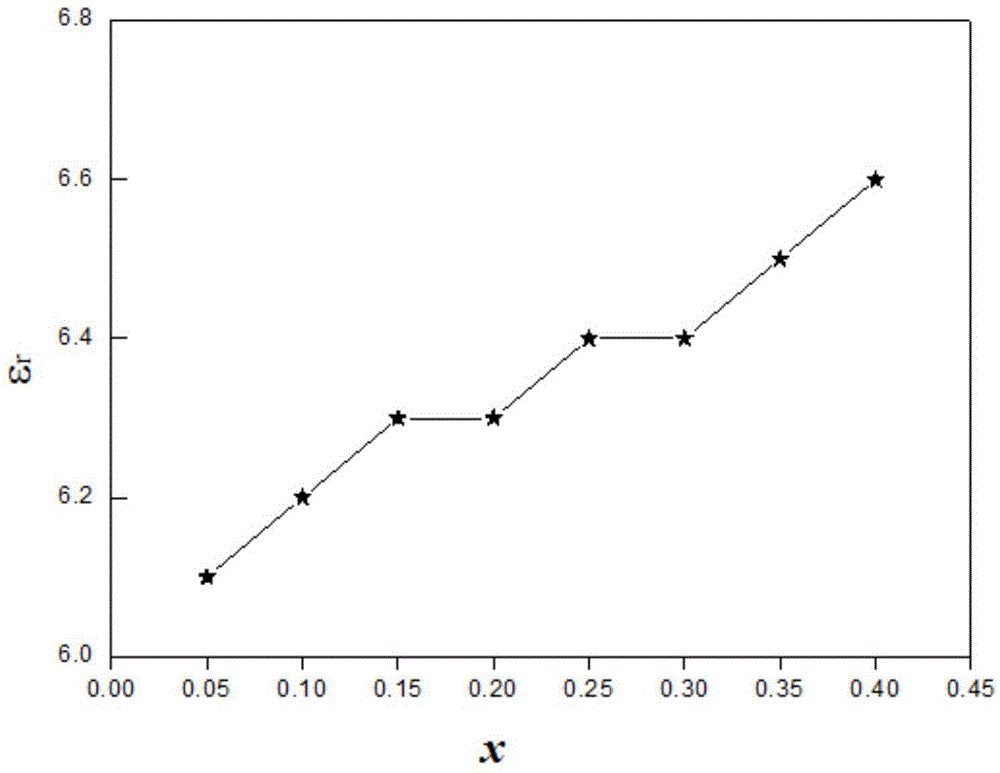

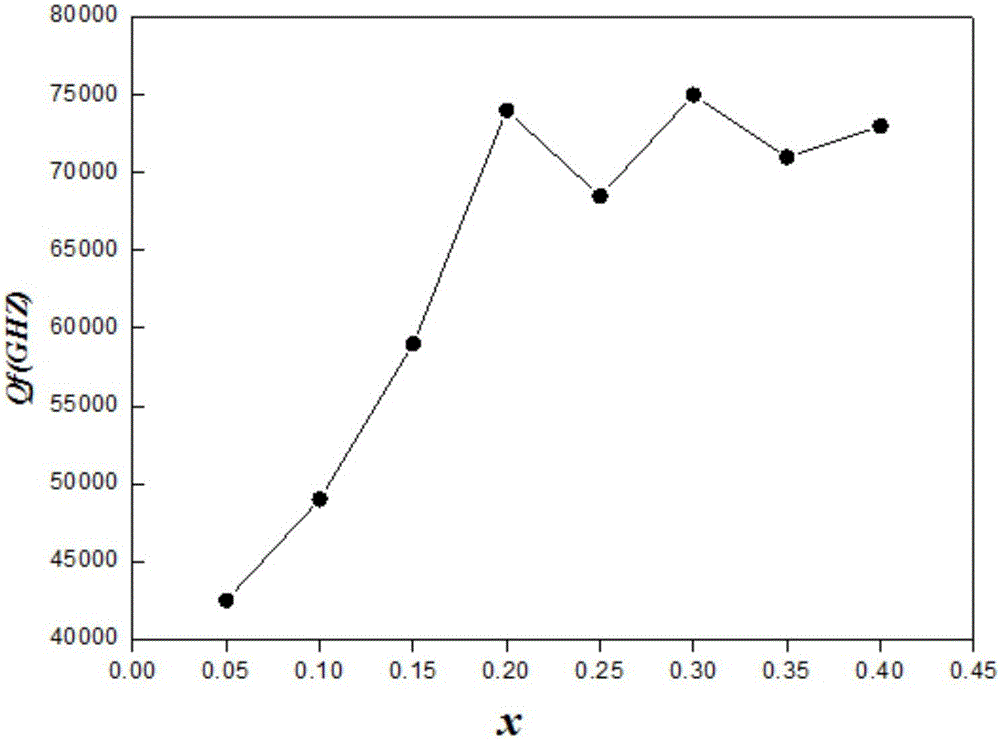

Image

Examples

example 1

[0028] Example 1: Preparation of Mg 2 Al 4 (Si 5-0.05 Ti 0.05 )O 18

[0029] Step (1). Selection of raw materials:

[0030] The purity (mass percentage) is 99.99% MgO, the purity (mass percentage) is 99.99% Al 2 o 3 , a purity (mass percentage) of 99.99% SiO 2 And purity (mass percentage composition) is 99.8% TiO 2 ;

[0031] Step (2). Ingredients and mixing:

[0032] MgO, Al 2 o 3 , SiO 2 、TiO 2 According to the chemical formula Mg 2 Al 4 (Si 5-x Ti x )O 18 For measurement, weigh 6.8854gMgO, 17.4012gAl 2 o 3 , 25.3794gSiO 2 , 0.3414gTiO 2 The raw material is ground with absolute ethanol as a grinding medium and ground in a ball mill for 24 hours to obtain a liquid mixture; then the liquid mixture is dried in an oven at 90°C to constant weight to obtain a dry mixture;

[0033] Step (3).Mg 2 Al 4 (Si 5-0.05 Ti 0.05 )O 18 Ceramic raw material pre-firing:

[0034] Pass the dry mixture obtained in step (2) through an 80-mesh standard sieve to disperse ...

example 2

[0045] Example 2: Preparation of Mg 2 Al 4 (Si 5-0.10 Ti 0.10 )O 18 ,

[0046] Step (1). Selection of raw materials:

[0047] The purity (mass percentage) is 99.99% MgO, the purity (mass percentage) is 99.99% Al 2 o 3 , a purity (mass percentage) of 99.99% SiO 2 And purity (mass percentage composition) is 99.8% TiO 2 ;

[0048] Step (2). Ingredients and mixing:

[0049] MgO, Al 2 o 3 , SiO 2 、TiO 2 According to the chemical formula Mg 2 Al 4 (Si 5-0.10 Ti 0.10 )O 18 For measurement, weigh 6.8738gMgO, 17.3719gAl 2 o 3 , 25.0807gSiO 2 , 0.6817gTiO 2 The raw material is ground with absolute ethanol as a grinding medium and ground in a ball mill for 24 hours to obtain a liquid mixture; then the liquid mixture is dried in an oven at 90°C to constant weight to obtain a dry mixture;

[0050] Step (3).Mg 2 Al 4 (Si 5-0.10 Ti 0.10 )O 18 Ceramic raw material pre-firing:

[0051] Pass the dry mixture obtained in step (2) through an 80-mesh standard sieve to d...

example 3

[0062] Example 3: Preparation of Mg 2 al 4 (Si 5-0.15 Ti 0.15 )O 18 ,

[0063] Step (1). Selection of raw materials:

[0064] The purity (mass percentage) is 99.99% MgO, the purity (mass percentage) is 99.99% Al 2 o 3 , a purity (mass percentage) of 99.99% SiO 2 And purity (mass percentage composition) is 99.8% TiO 2 ;

[0065] Step (2). Ingredients and mixing:

[0066] MgO, Al 2 o 3 , SiO 2 、TiO 2 According to the chemical formula Mg 2 al 4 (Si 5-0.15 Ti 0.15 )O 18 For measurement, weigh 6.8622gMgO, 17.3427gAl 2 o 3 , 24.7830gSiO 2 , 1.0208gTiO 2 The raw material is ground with absolute ethanol as a grinding medium and ground in a ball mill for 24 hours to obtain a liquid mixture; then the liquid mixture is dried in an oven at 90°C to constant weight to obtain a dry mixture;

[0067] Step (3).Mg 2 al 4 (Si 5-0.15 Ti 0.15 )O 18 Ceramic raw material pre-firing:

[0068] Pass the dry mixture obtained in step (2) through an 80-mesh standard sieve to d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Quality factor | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com