Method for preparing tomato soilless culture substrate

A technology of soilless cultivation substrate and tomato, applied in the field of preparation of tomato soilless cultivation substrate, can solve the problems of waste of resources, pollution of the environment, etc., and achieve the effect of vigorous growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

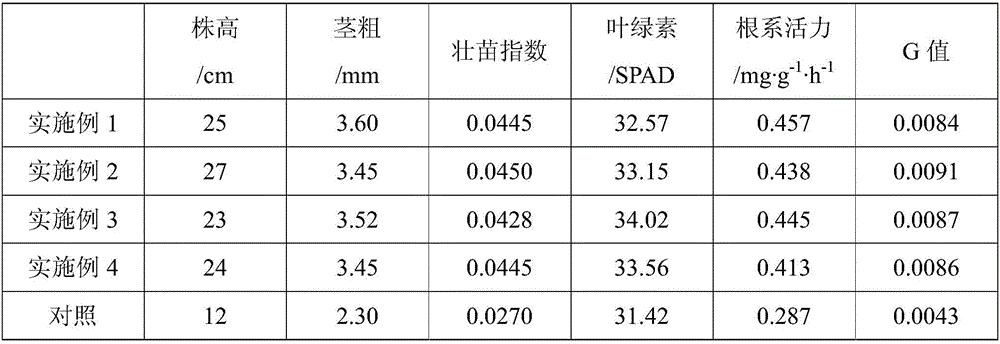

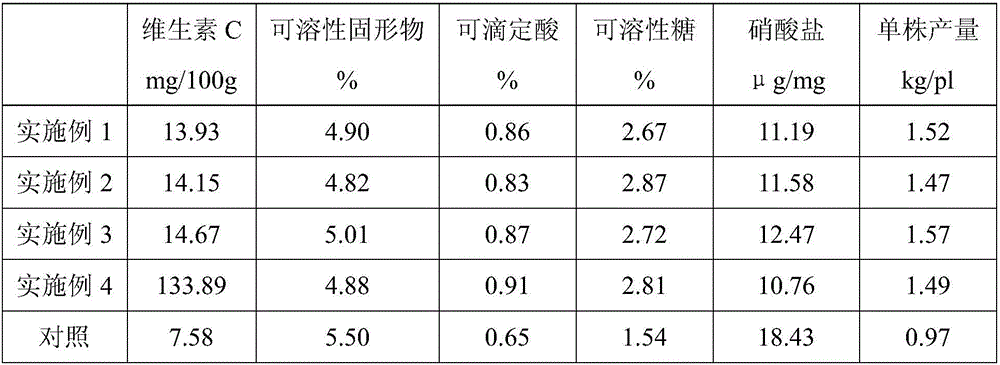

Examples

Embodiment 1

[0020] A preparation method for tomato soilless cultivation substrate, comprising the following steps:

[0021] Step 1, taking corn stalks, drying and crushing to obtain straw granules;

[0022] Step 2, putting the straw granules in the pretreatment solution to cook for 2 hours, adjusting the pH of the cooking solution to 8.0, and filtering to obtain the pretreatment granules;

[0023] Step 3, adding the pretreatment granules to leaching in a phosphate buffer solution containing a mass concentration of 1% compound enzyme, the compound enzyme refers to a cellulase with a mass ratio of 2: 1: protease, deactivates the enzyme, and filters to obtain Enzyme granules;

[0024] Step 4, in parts by weight, mix 10 parts of enzymolysis granules with 2 parts of chicken manure, add 0.2 part of diammonium hydrogen phosphate, 0.1 part of magnesium sulfate heptahydrate, 0.3 part of manganese sulfate, 0.1 part of chitosan, 0.2 parts of nicotinamide, 0.4 parts of gypsum, 1 part of water, high...

Embodiment 2

[0028] A preparation method for tomato soilless cultivation substrate, comprising the following steps:

[0029] Step 1, taking corn stalks, drying and crushing to obtain straw granules;

[0030] Step 2, putting the straw granules in the pretreatment solution to cook for 4 hours, adjusting the pH of the cooking solution to 9.0, and filtering to obtain the pretreatment granules;

[0031] Step 3, add the pretreatment granule to the phosphate buffer solution containing mass concentration 3% compound enzyme and extract, and described compound enzyme refers to the cellulase of mass ratio 2: 1: Protease, inactivate enzyme, filter, obtain Enzyme granules;

[0032] Step 4, in parts by weight, mix 10 parts of enzymolysis granules with 3 parts of chicken manure, add 0.5 parts of diammonium hydrogen phosphate, 0.3 parts of magnesium sulfate heptahydrate, 0.6 parts of manganese sulfate, 0.2 parts of chitosan, 0.4 parts of nicotinamide, 0.5 parts of gypsum, 3 parts of water, high-temperat...

Embodiment 3

[0036] A preparation method for tomato soilless cultivation substrate, comprising the following steps:

[0037] Step 1, taking corn stalks, drying and crushing to obtain straw granules;

[0038] Step 2, putting the straw granules in the pretreatment solution to cook for 4 hours, adjusting the pH of the cooking solution to 8.0, and filtering to obtain the pretreatment granules;

[0039] Step 3, add the pretreatment granule to the phosphate buffer solution containing mass concentration 3% compound enzyme and extract, and described compound enzyme refers to the cellulase of mass ratio 2: 1: Protease, inactivate enzyme, filter, obtain Enzyme granules;

[0040] Step 4, in parts by weight, mix 10 parts of enzymolysis granules with 4 parts of chicken manure, add 0.3 parts of diammonium hydrogen phosphate, 0.2 parts of magnesium sulfate heptahydrate, 0.6 parts of manganese sulfate, 0.1 parts of chitosan, 0.4 parts of nicotinamide, 0.8 parts of gypsum, 4 parts of water, high-temperat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com