Method for disposing fine-grain-containing tailings on basis of biological lamina heap construction

A thin-layer and stacking technology, which is applied in the field of high-containing fine-grained tailings based on biological thin-layered stacking and biological thin-layered stacking, can solve the problems of bioleaching of fine-grained tailings and other problems, so as to improve bioleaching efficiency, The effect of simple stacking method, improved growth and leaching efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

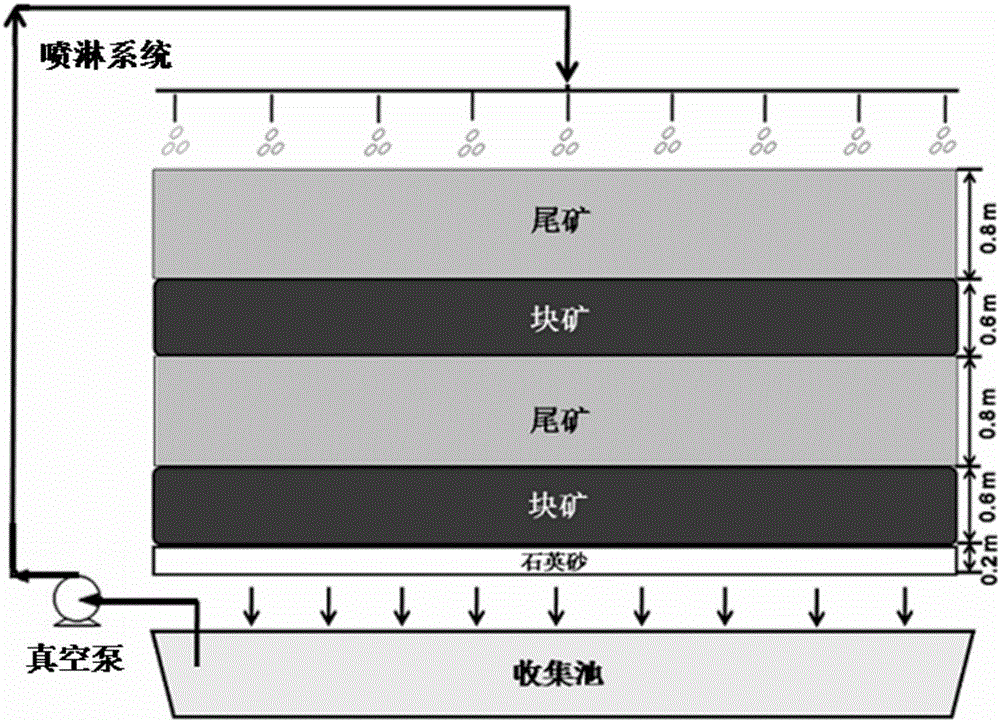

Method used

Image

Examples

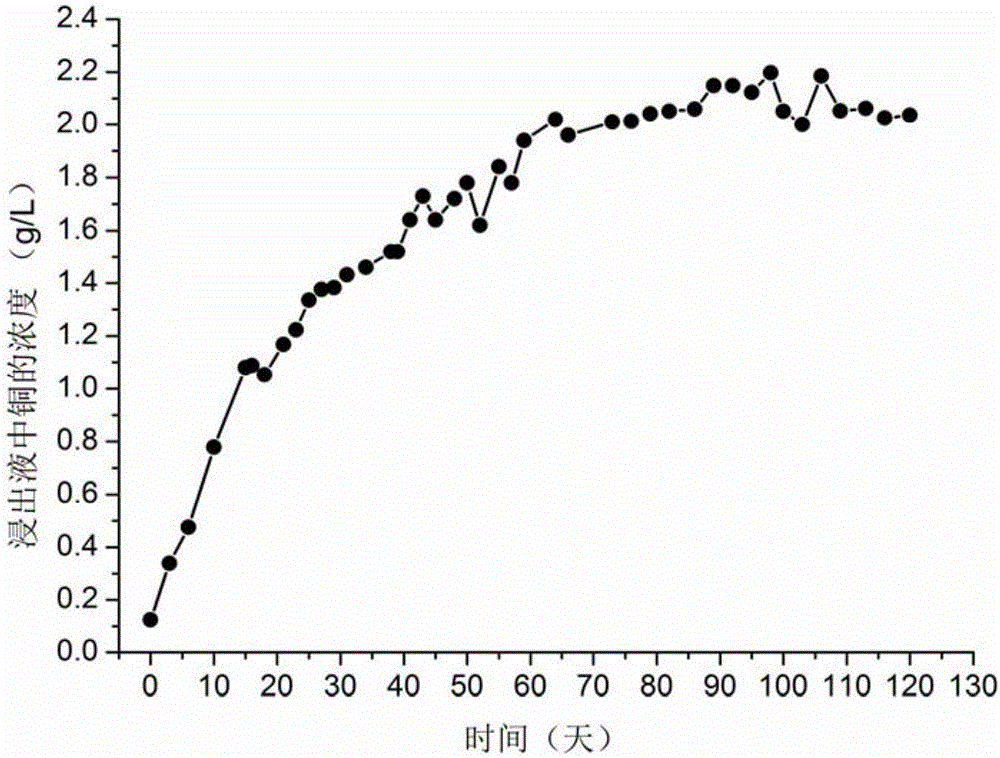

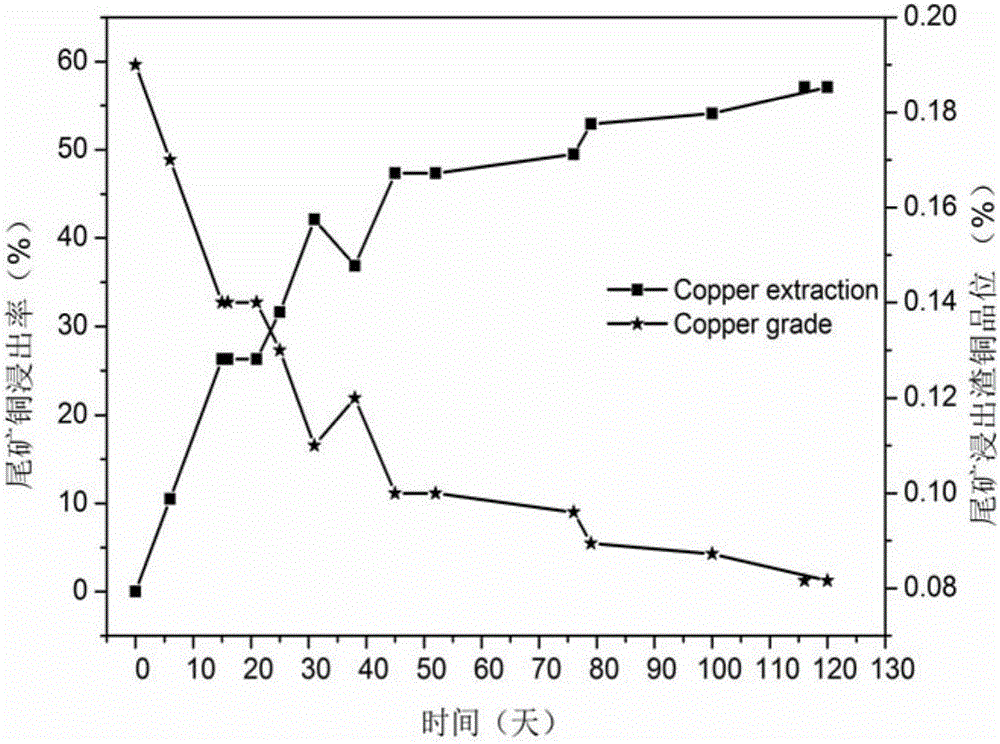

Embodiment 1

[0042] The copper flotation tailings come from the Lualo tailings pond in Zambia, with a copper grade of 0.19%. Tailings particle size distribution (w / w) is: tailings smaller than 75 μm accounted for 48%, and tailings of 75-150 μm accounted for 52%. The phase distribution of copper in the tailings is (w / w): 35.26% primary copper sulfide, 28.95% secondary copper sulfide, 29.47% free copper oxide, and 6.32% combined copper oxide. The lump ore used comes from Dexing Copper Mine in Jiangxi, with a copper grade of 0.58%, iron content of 17.50%, and sulfur content of 15.85%.

[0043] Mixed acidophilic microbial flora for thin layer leaching of tailings consists of acidophilic Thiobacillus ferrooxidans, acidophilic Thiobacillus thiooxidans, Leptospira ferrooxidans, mesophilic Sulfobacillus sulfuroxidans, thermoacidophilic ferric Composition of bacteria. Before mixing, various ore leaching microorganisms are cultured separately, and the basic salt medium components include (NH 4 ) ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com