Four-in-one brush coating chemical conversion solution

A technology of chemical conversion and conversion liquid, applied in the direction of metal material coating process, etc., can solve the problem of operator hazards, and achieve the effects of comprehensive cost reduction, good film formation and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] A four-in-one brush coating chemical conversion solution, the composition of which includes the following components by weight: 10 parts of degreasing agent, 30 parts of rust remover, 100 parts of film forming agent, 5 parts of oxidizing agent, 10 parts of complexing agent, corrosion inhibitor 2 parts of agent, add water to 1000 parts, and adjust the pH value to 1.75.

[0036] The method of using the above-mentioned four-in-one brushing chemical conversion liquid is as follows: first remove the heavy oil and floating rust on the surface of 35CrMnSi steel, and keep the brushed surface dry; After the surface is slightly dry, brush off the air bubbles and excess conversion liquid on the surface; finally place it in a ventilated place to dry naturally.

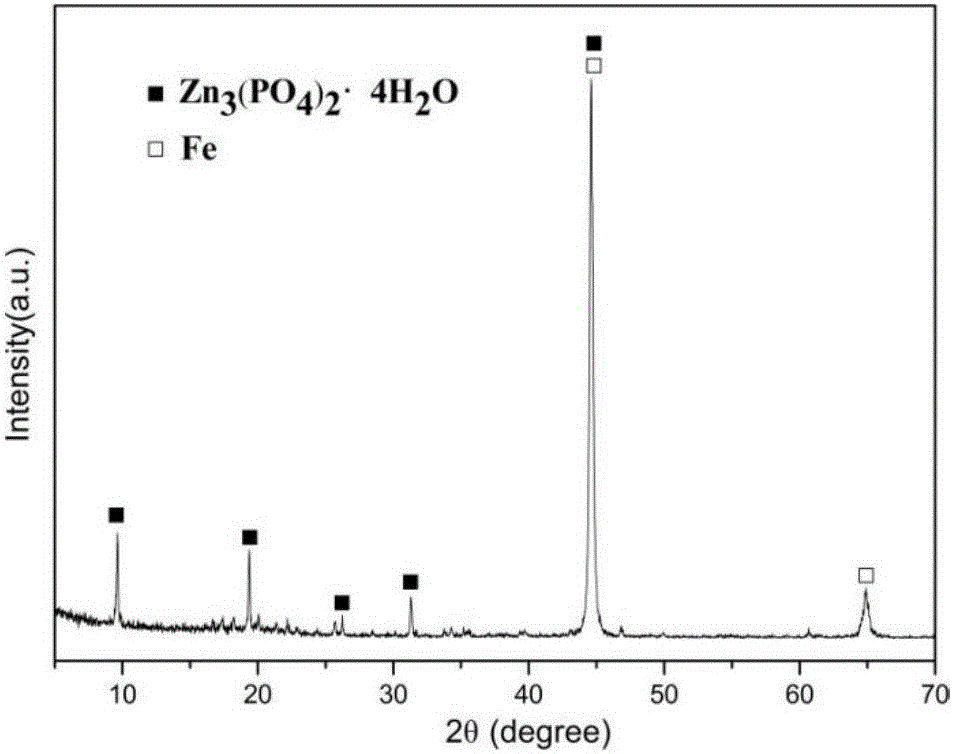

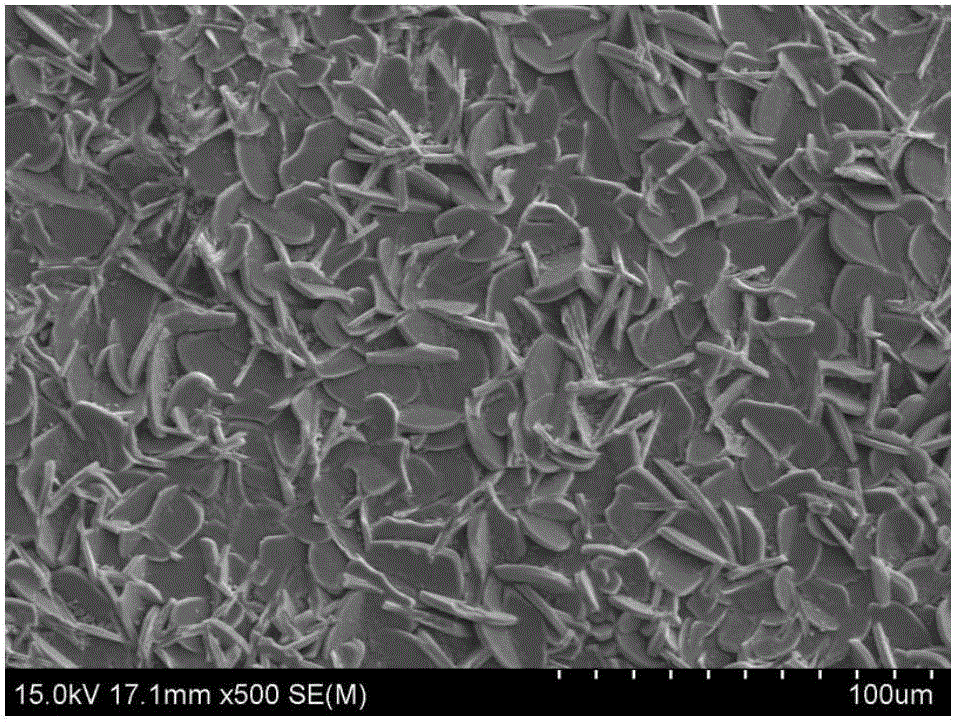

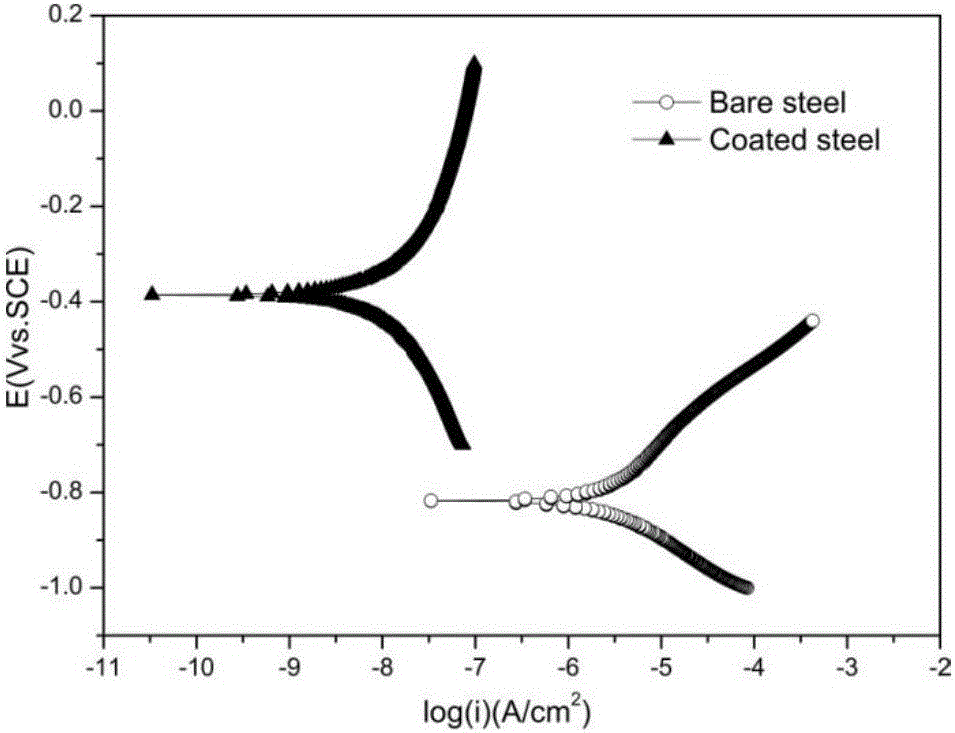

[0037] Depend on figure 1 It can be seen that the phase composition of the brush-coated conversion coating is zinc phosphate (Zn 3 (PO 4 )2 4H 2 O). Zinc phosphate itself has good corrosion resistance and is a non-cond...

Embodiment 2

[0039] A four-in-one brush coating chemical conversion solution, the composition of which includes the following components by weight: 15 parts of degreasing agent, 25 parts of rust remover, 90 parts of film forming agent, 3 parts of oxidizing agent, 12 parts of complexing agent, corrosion inhibitor 4 parts of agent, add water to 1000 parts, and adjust the pH value to 2.0.

[0040] The method of using the above-mentioned four-in-one brushing chemical conversion liquid is as follows: first remove the heavy oil and floating rust on the surface of 35CrMnSi steel, and keep the brushed surface dry; After the surface is slightly dry, brush off the air bubbles and excess conversion liquid on the surface; finally place it in a ventilated place to dry naturally.

Embodiment 3

[0042] A four-in-one brush coating chemical conversion liquid, its composition includes the following components by weight: 12 parts of degreasing agent, 35 parts of rust remover, 120 parts of film forming agent, 6 parts of oxidizing agent, 13 parts of complexing agent, corrosion inhibitor 5 parts of agent, add water to 1000 parts, and adjust the pH value to 1.6.

[0043] The method of using the above-mentioned four-in-one brushing chemical conversion liquid is as follows: first remove the heavy oil and floating rust on the surface of the 35CrMnSi steel, and keep the brushed surface dry; After the surface is slightly dry, brush off the air bubbles and excess conversion liquid on the surface; finally place it in a ventilated place to dry naturally.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com