Novel large-inertia rotating-shaft braking system

A brake system and large inertia technology, applied in the direction of axial brakes, brake types, fluid pressure actuators, etc., can solve the problems of long braking time, limited braking capacity, and limited travel of brake hydraulic cylinders, etc., to avoid Safety accidents, significant braking effect, and good system stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with accompanying drawing:

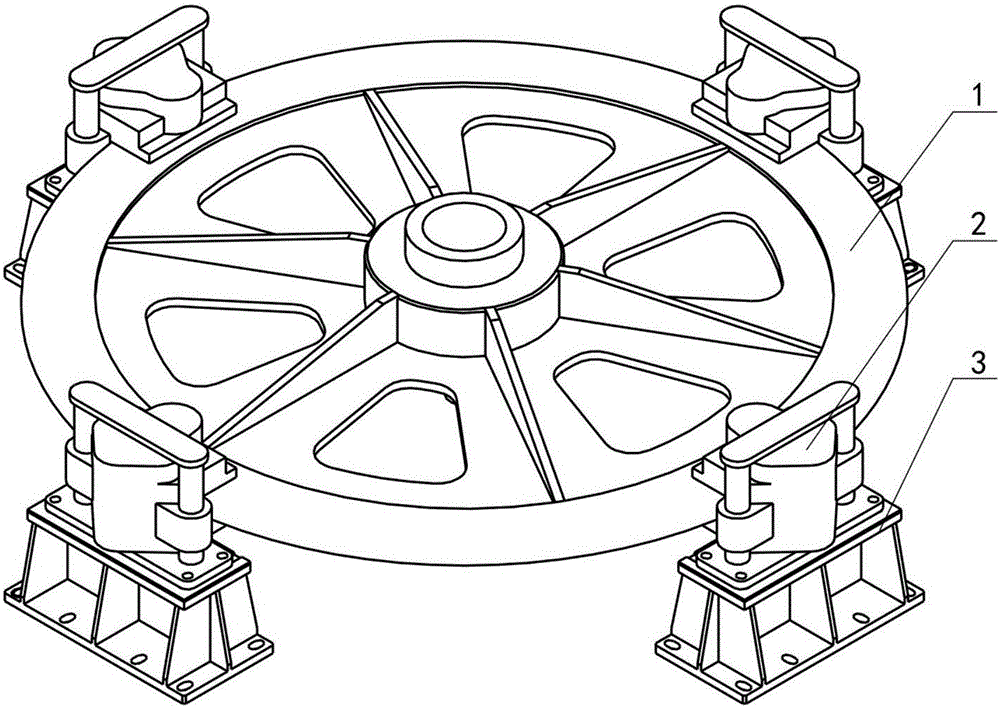

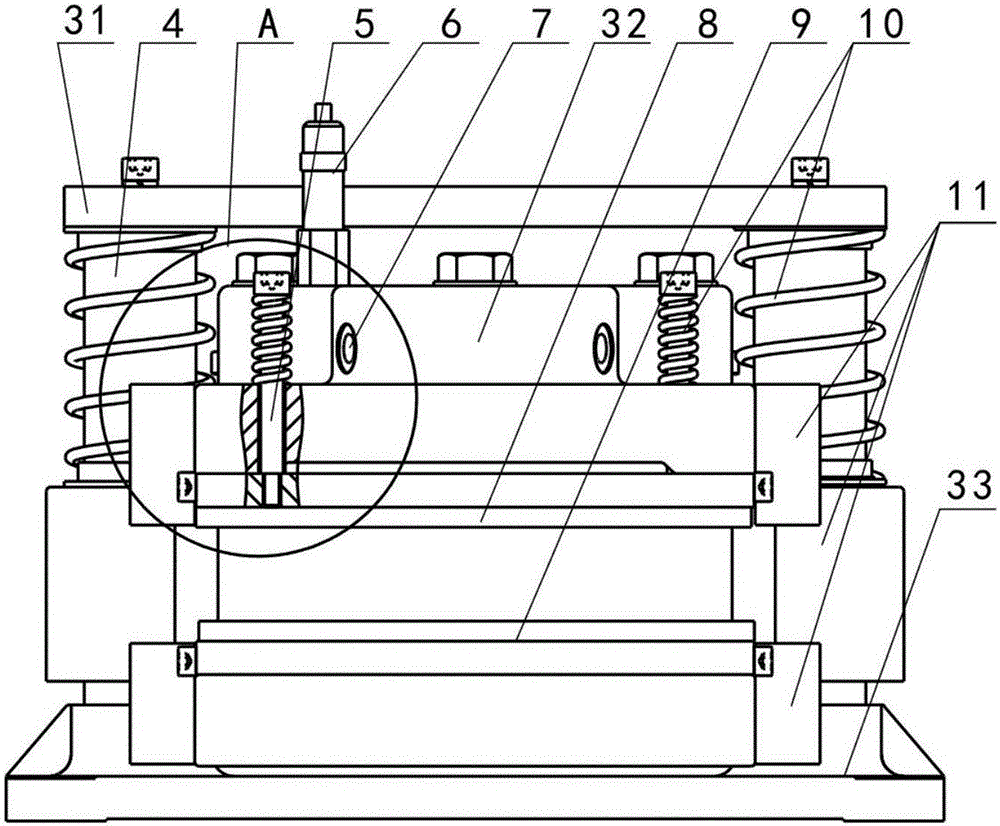

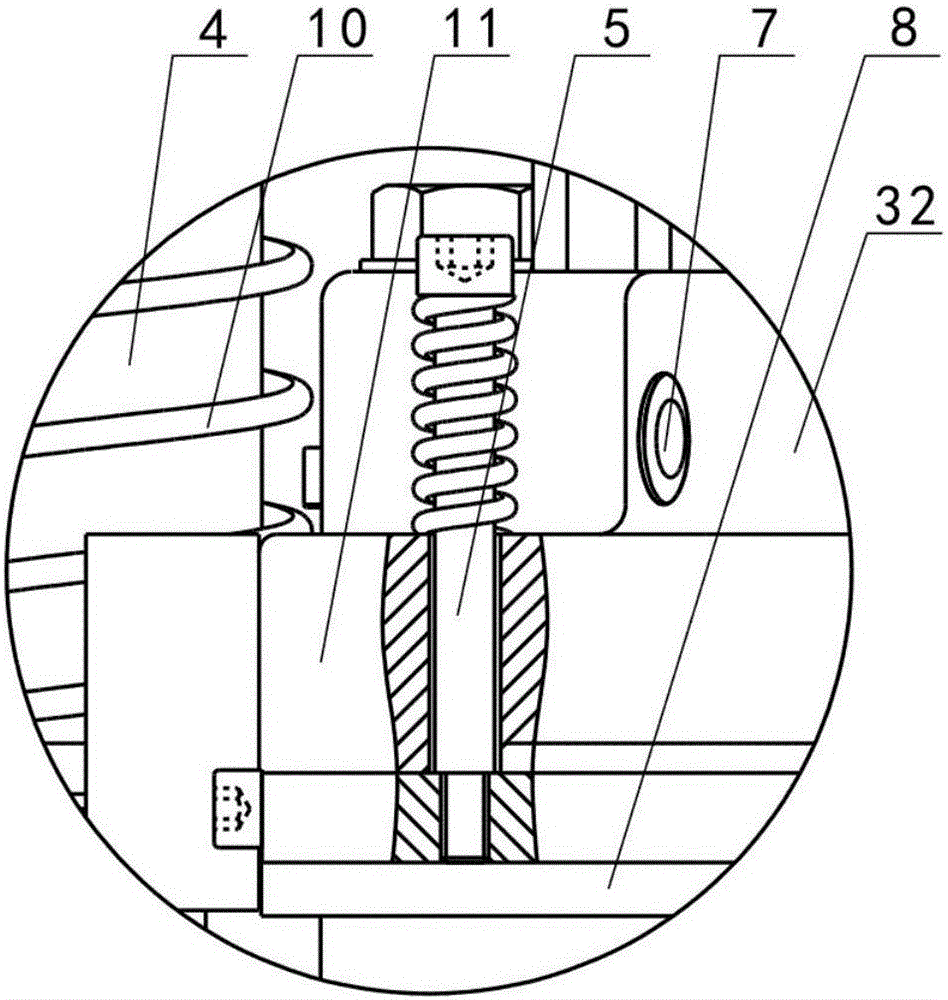

[0023] Such as figure 1 As shown, the novel large inertia rotating shaft brake system of the present invention includes a brake mounting bracket 3, a brake 2 and a brake disc 1, such as Figure 2-Figure 8 As shown, the brake 2 includes a mounting base 33, a guide column 4, a base body 11, a hydraulic cylinder 32, an upper brake pad 8, a lower brake pad 9 and a travel sensor 6, and the two guide columns 4 are vertically installed on the mounting base 33. The two ends of the base body 11 are respectively fitted on the two guide columns 4 through their own through holes and can move axially. The tops of the two guide columns 4 are fixedly connected by a connecting plate 31, and the hydraulic cylinder 32 is installed on the base body 11. The brake pad 8 is connected with the piston rod of the hydraulic cylinder 32 (not shown in the figure, which is a conventional structure), t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com