Condensation-type air-preheating flue gas waste heat recycling device

A technology of air preheating and flue gas waste heat, applied in the field of gas boilers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the accompanying drawings.

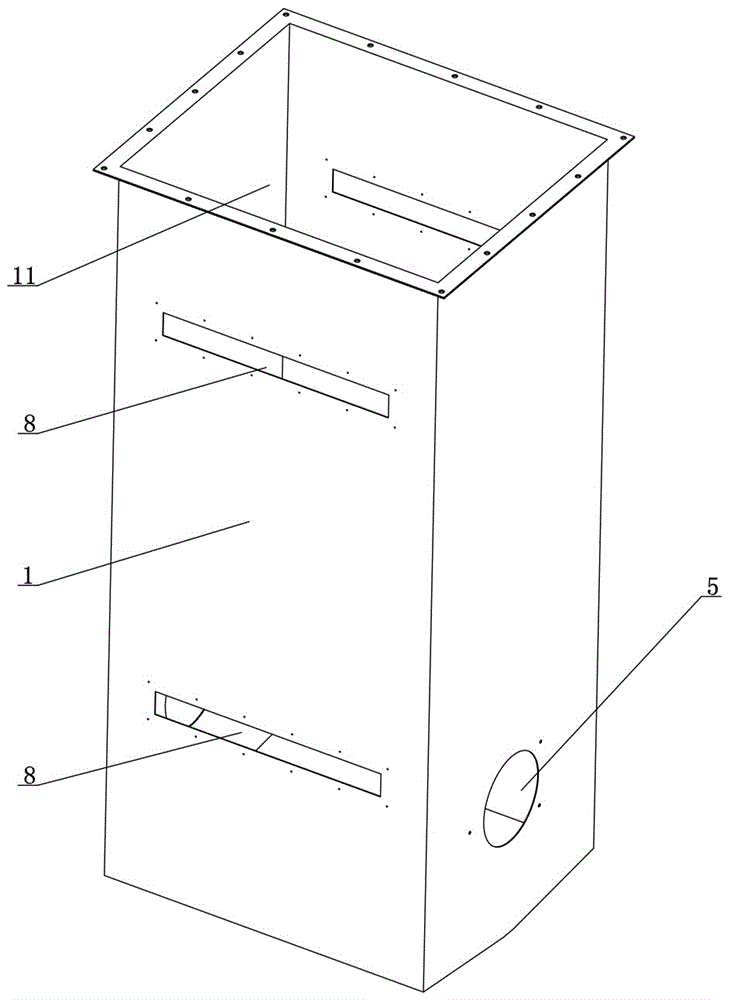

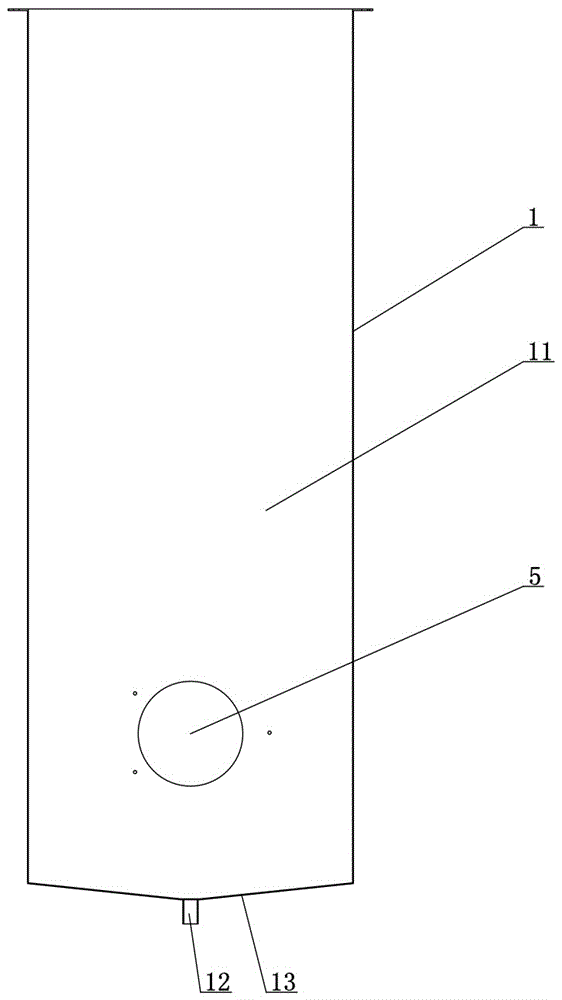

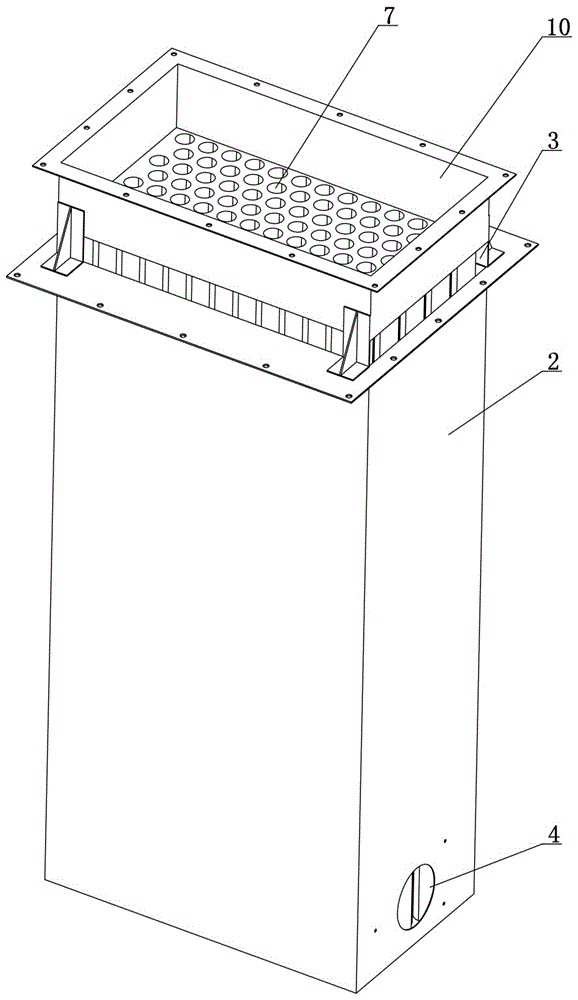

[0030] According to attached figure 1 to attach Figure 8 As shown, the condensing air preheating flue gas waste heat recovery device of the present invention includes a flue assembly for collecting flue gas generated by the gas module. The flue assembly includes a condensing outer shell 1 and a condensing inner shell 2 , the condensing outer shell 1 has a condensing cavity 11 , the condensing inner shell 2 has a condensing inner cavity 21 , and the condensing inner shell 2 is installed on the condensing cavity 11 . The top of the condensing inner shell 2 is provided with an air inlet 3 communicating with the condensing inner cavity 21, and the bottom of the condensing inner shell 2 is provided with an air outlet 4 that can be communicated with the condensing inner cavity 21 and the condensing chamber 11 respectively. An exhaust port 5 communicating with the condensa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com