Composite high-efficiency solar energy hot wind generation apparatus

A solar hot air generation device technology, applied in the field of solar energy utilization, can solve problems such as poor thermal conductivity, low hot air temperature, pollution, etc., and achieve the effects of improving thermal energy utilization, improving heat exchange efficiency, and increasing application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

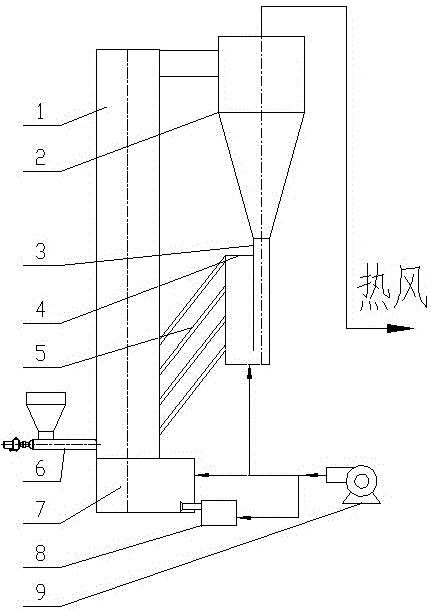

[0042] The bed material enters the main bed 1 after being heated to 280°C in the solar heater 5, and the air at 20°C

[0043] The fan 9 enters from the bottom of the main bed 1 through the air chamber 7, and the incoming air is heated by the bed material into hot air.

[0044] air, and the bed material is blown into the cyclone separator 2, and the bed material and hot air are realized in the cyclone separator 2

[0045] Air separator, the hot air is discharged from the top of the cyclone separator 2, the temperature of the hot air when discharged

[0046] The temperature is 260°C, and the bed material enters the solar heater 5 from the standpipe 3 and the feeder 4 for refilling.

[0047] hot.

Embodiment 2

[0049] The bed material enters the main bed 1 after being heated to 300°C in the solar heater 5, and the air at 15°C is

[0050] The fan 9 enters from the bottom of the main bed 1 through the air chamber 7, and the incoming air is heated by the bed material to become hot air.

[0051] And the bed material is blown into the cyclone separator 2, and the bed material and hot air are separated in the cyclone separator 2

[0052] Separator, the hot air is discharged from the top of the cyclone separator 2, and the temperature of the hot air when discharged is

[0053] At 290°C, the bed material enters the solar heater 5 from the standpipe 3 and the feeder 4 for reheating.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap