Built-in self test circuit and self test method for parallel plate capacitive MEMS (Micro-Electro-Mechanical-System) accelerometer

A built-in self-test, parallel plate capacitance technology, applied in the testing/calibration of speed/acceleration/shock measurement equipment, speed/acceleration/shock measurement, measurement of acceleration, etc. Complex micro-mechanical structure and other problems, to achieve the effect of saving use costs, convenient operation and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with specific drawings and embodiments.

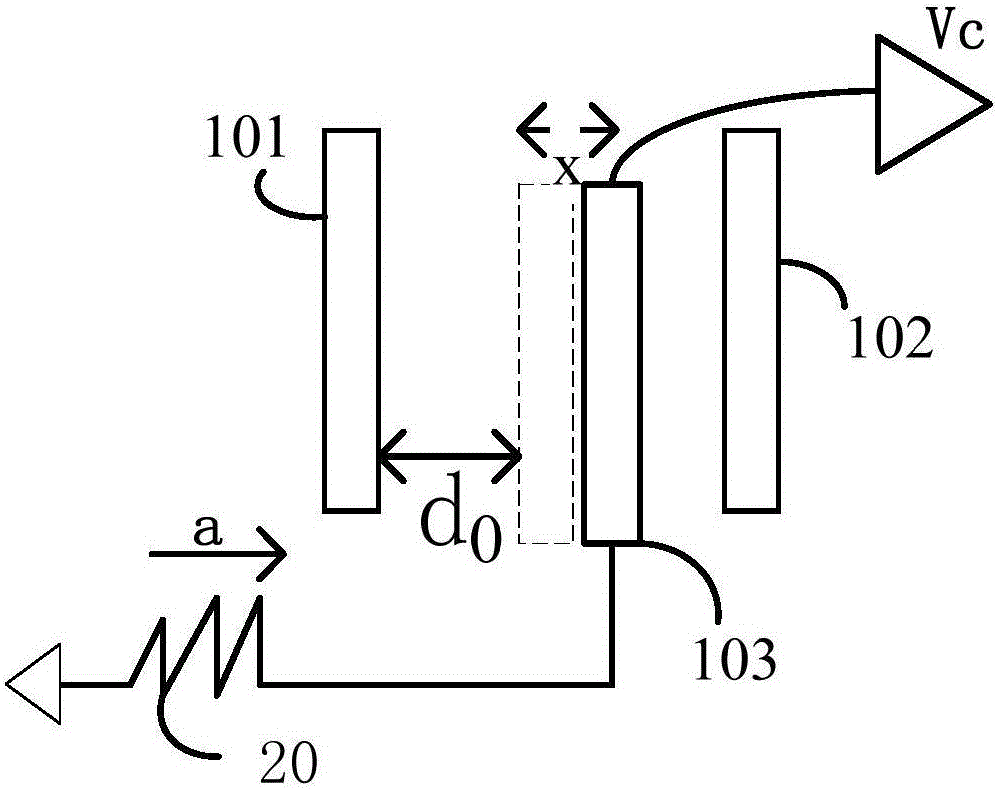

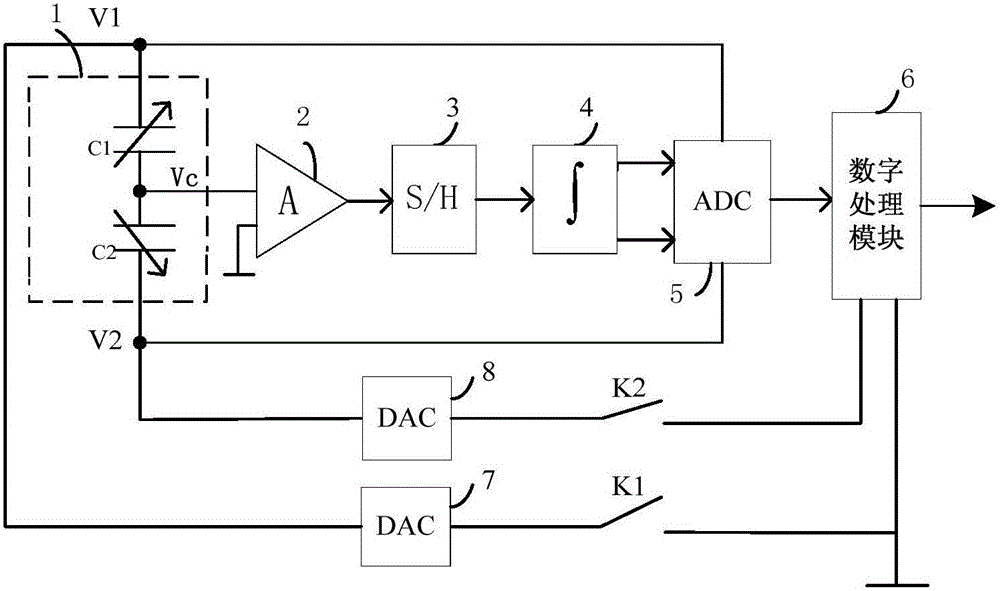

[0021] figure 1 It is a typical parallel plate capacitive MEMS accelerometer, including a capacitive sensing module 1 and a spring mass 20; the capacitive sensing module 1 includes two opposite fixed plates 101, 102, and is located between the two fixed plates The movable pole plate 103; the variable capacitors C1 and C2 are formed between the movable pole plate 103 and the two fixed pole plates 101, 102; the initial position of the movable pole plate 103 is located in the middle of the two fixed pole plates 101, 102; The spring mass 20 is connected to the movable polar plate 103; in the present invention, a typical MEMS accelerometer operating mode is adopted, that is, a second-order spring-mass-damping system; the typical mathematical formula that can be expressed is:

[0022] m x ·· + b ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com