A four-stage degassing method for insulating oil of UHV transmission and transformation transformers

A technology for transformer insulating oil and power transmission and transformation, which is applied in the field of four-stage degassing of insulating oil for ultra-high voltage power transmission and transformation transformers, can solve the problems of only being applicable, and achieves fast degassing speed, good degassing effect, and shortened air retention time. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Below in conjunction with example the present invention will be further described.

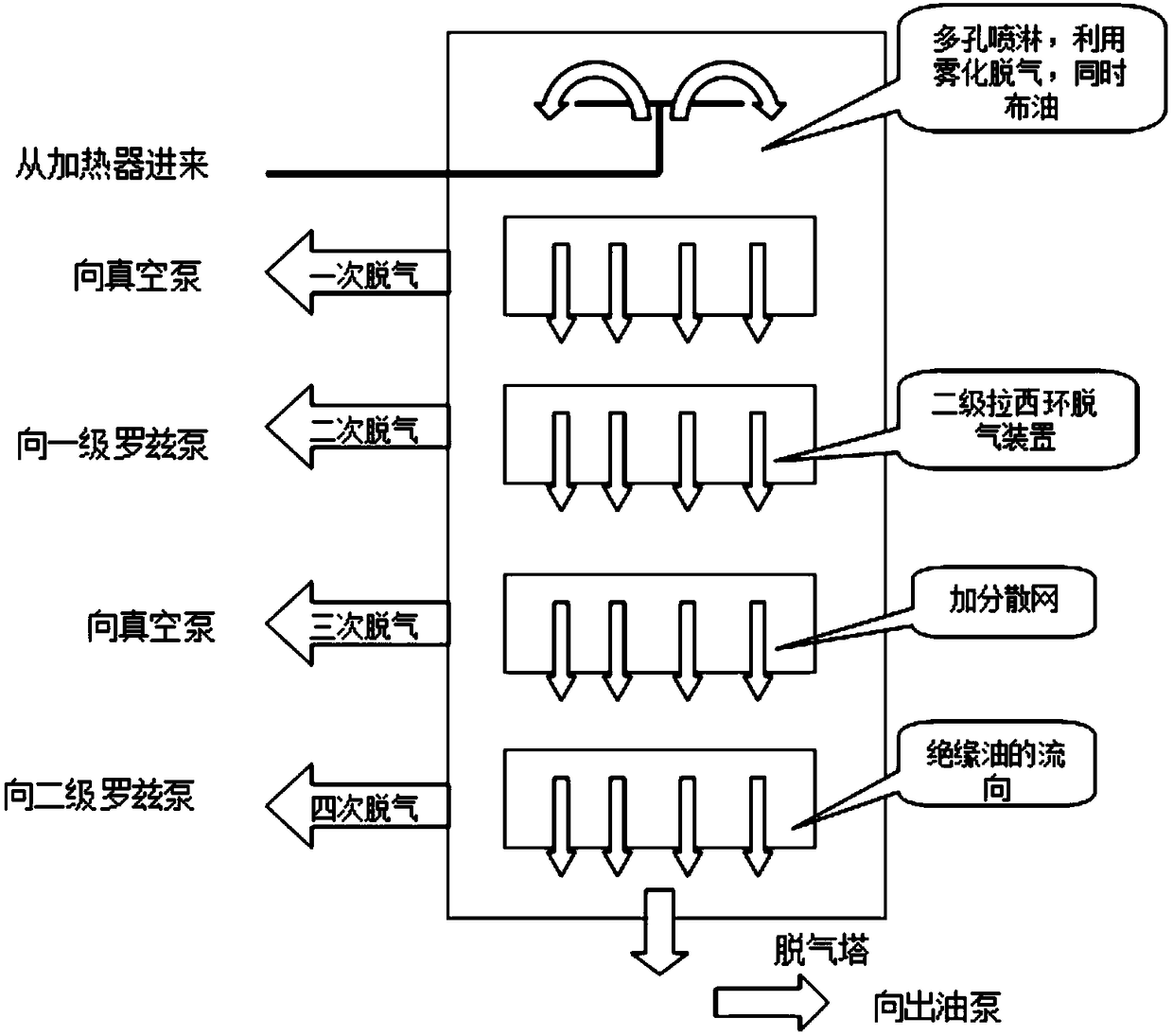

[0017] The initial pressure of the transformer insulating oil is 1 bar, the initial temperature is 30°C, and the gas content is 1% (volume ratio); it first enters the first-stage spray drying zone for degassing, and after being heated by an electric heater, the temperature of the insulating oil rises to 110°C. The oil liquid is separated into semi-mist through the spray wing, and the water in the oil evaporates rapidly into water vapor, which is pumped out by the vacuum pump, and the vacuum degree reaches 400Pa; the gas content is reduced to 0.7% (volume ratio), and then enters the second stage of Raschig Thin film evaporation is carried out in the ring area and degassed again; after degassing again, the vacuum degree of the system reaches 100Pa, its temperature reaches 125°C, and the gas content is reduced to 0.3% (volume ratio); the insulating oil after these two stages of degassing is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com