A high conductance high reliability ce‑sn‑ag‑cu solder for electronic packaging

An electronic packaging, ce-sn-ag-cu technology, applied in the field of high-conductivity and high-reliability Ce-Sn-Ag-Cu solder, can solve the problems of solder conductivity and reliability that cannot meet the strict requirements of electronic packaging, and achieve Improve oxidation and corrosion resistance, electrical and thermal conductivity, high dimensional stability, and strong drop resistance of solder joints

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

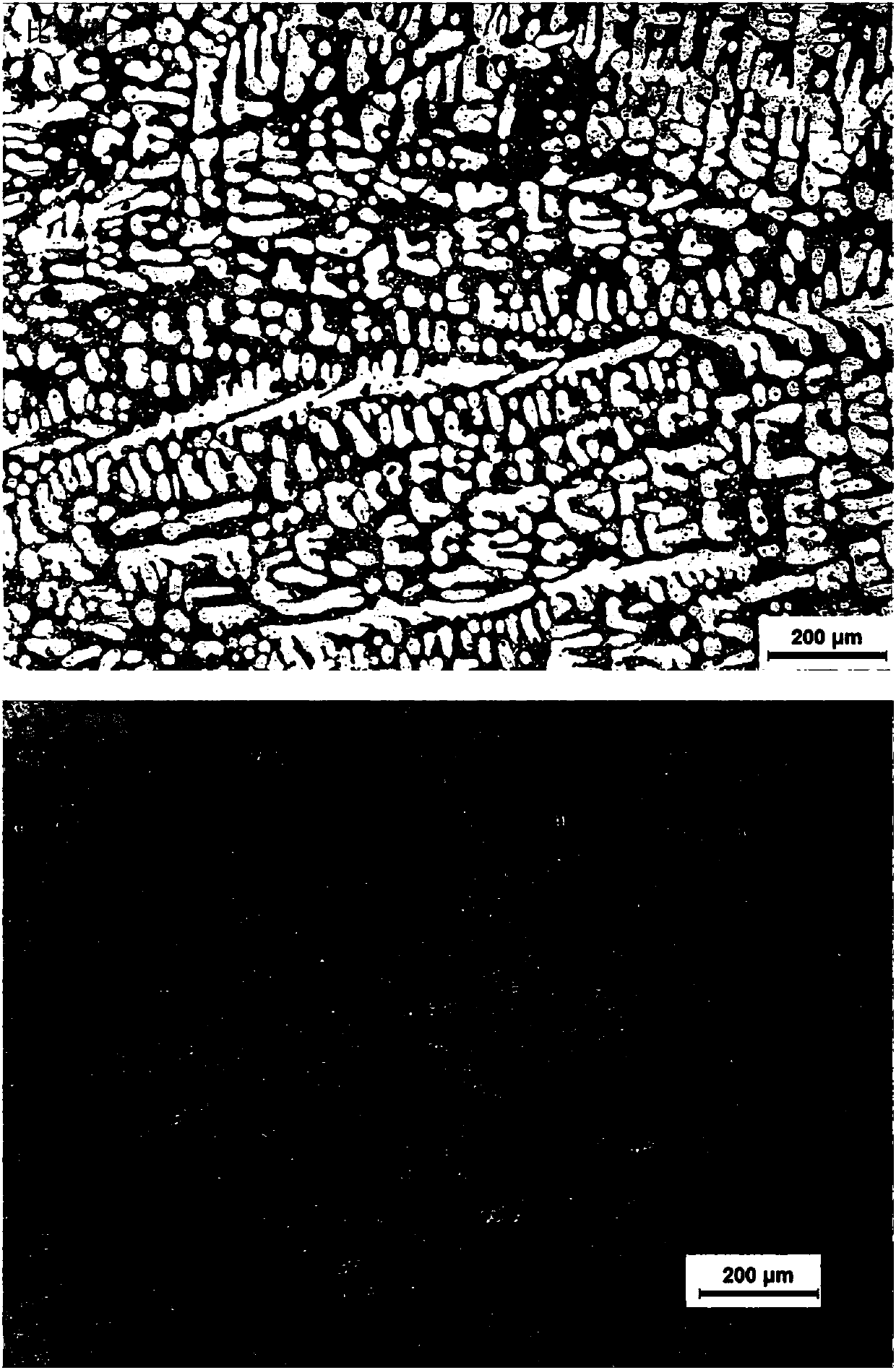

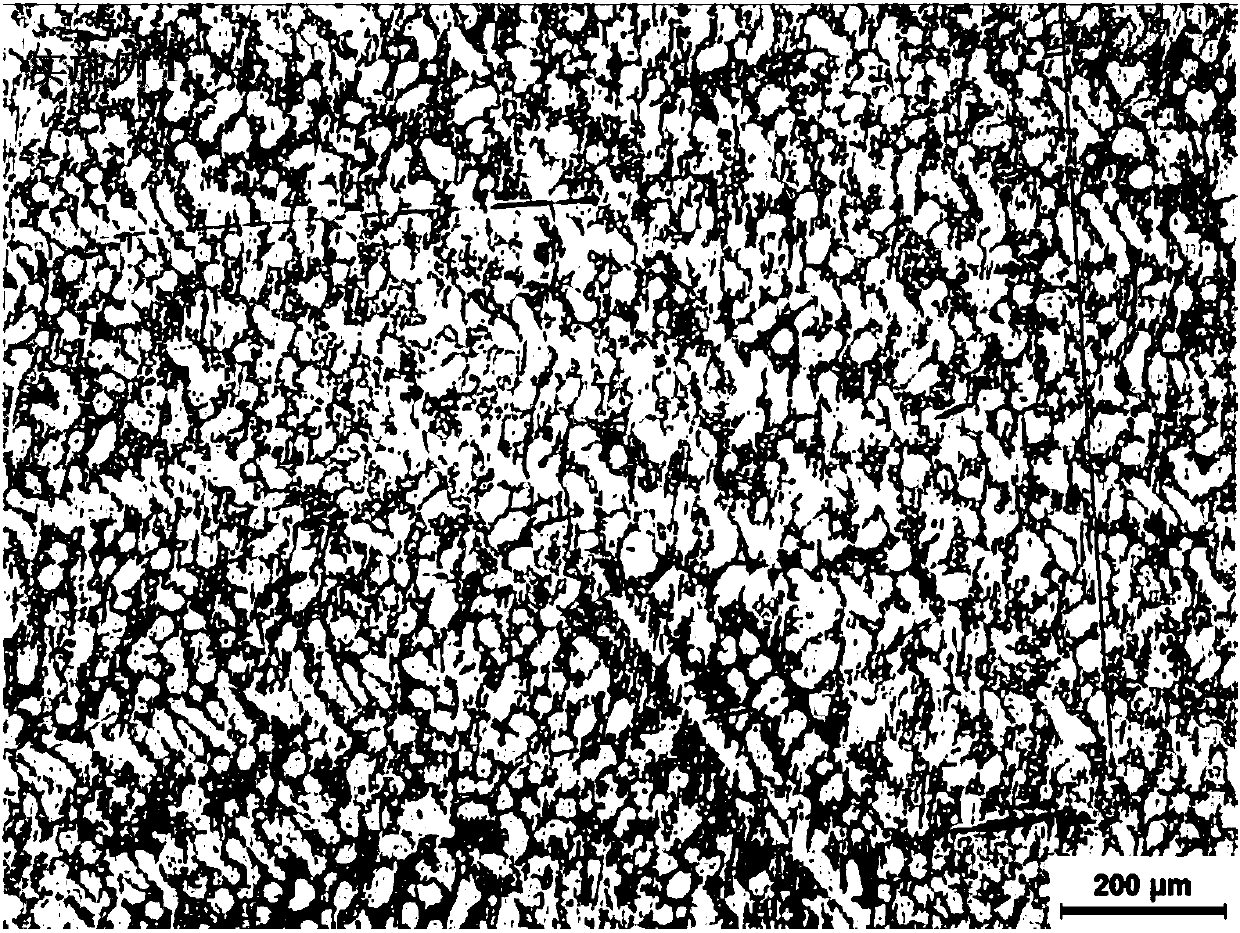

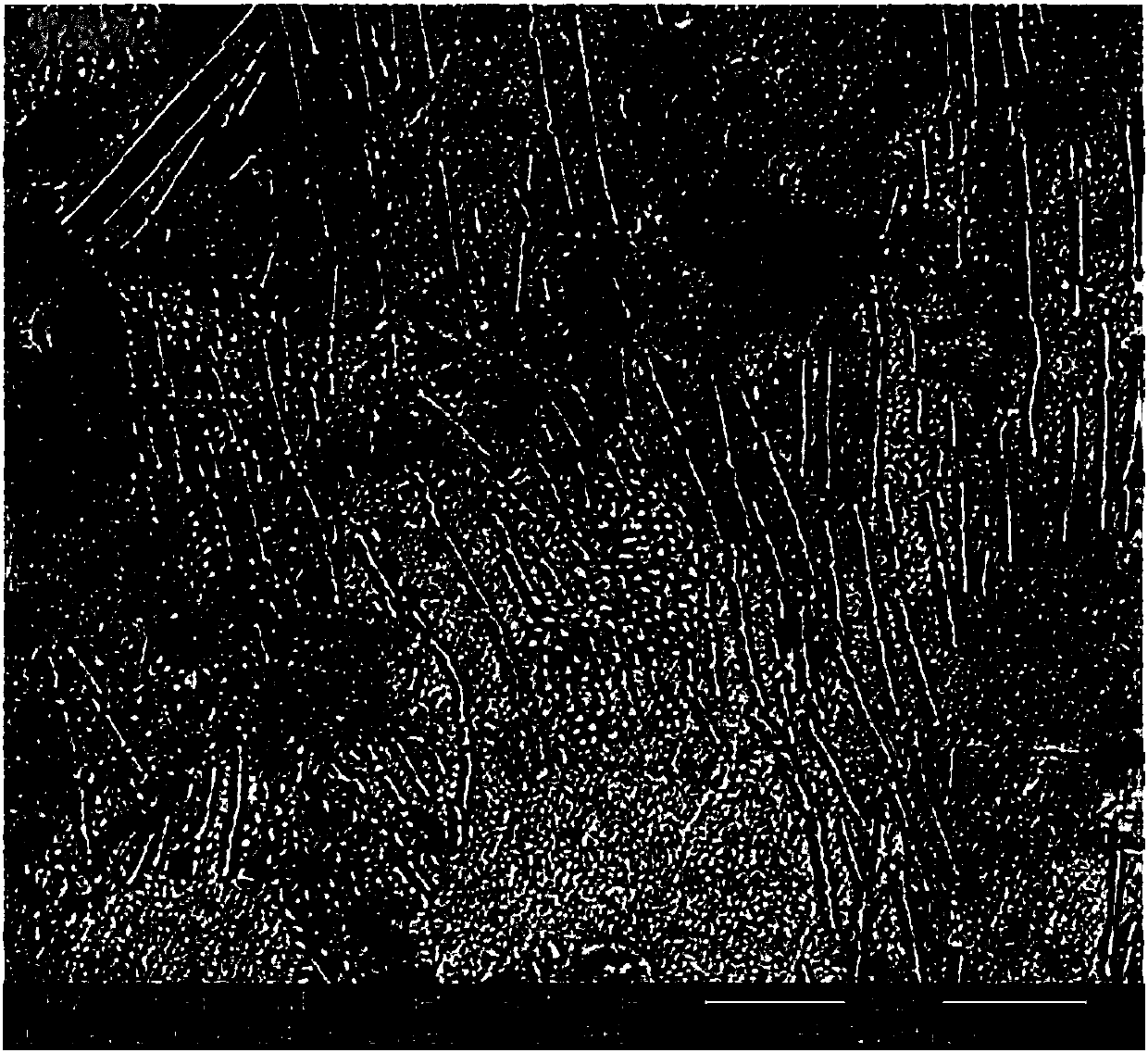

Image

Examples

Embodiment Construction

[0025] A high-conductivity and high-reliability Ce-Sn-Ag-Cu solder suitable for electronic packaging. The main metal elements of the solder alloy are Ce, Sn, Ag, Cu and Be. Solder may also contain unavoidable impurity elements.

[0026] As a further improvement of the above solder, the mass percentage of the main metal elements in the solder alloy is: Ag: 2.0-3.8%, Cu: 0.4-0.7%, Ce: 0.01-0.7%, Be: 0.01-1.0%, and the balance is Sn .

[0027] As a further improvement of the above solder, the mass percentage of the main metal elements in the solder alloy is: Ag: 3.0-3.8%, Cu: 0.5-0.7%, Ce: 0.02-0.7%, Be: 0.2-0.5%, and the balance is Sn .

[0028] As a further improvement of the above solder, the mass addition ratio of Ag to Cu in the solder alloy is (5-6):1, preferably, the mass addition ratio of Ag to Cu is (5-5.4):1.

[0029] As a further improvement of the above solder, the mass addition ratio of Ce and Be in the solder alloy is 1:(1-2), preferably, the mass addition ratio ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com