A hexagonal honeycomb and its preparation method and application

A hexagonal and semi-hexagonal technology, applied in the field of hexagonal honeycomb and its preparation, can solve the problems of low production efficiency, incapable of continuous production, complicated preparation process, etc., and achieves improved strength, improved production efficiency and good benefit. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below through specific embodiments. The following examples are preferred implementation forms of the present invention, but the implementation manners of the present invention are not limited by the following examples.

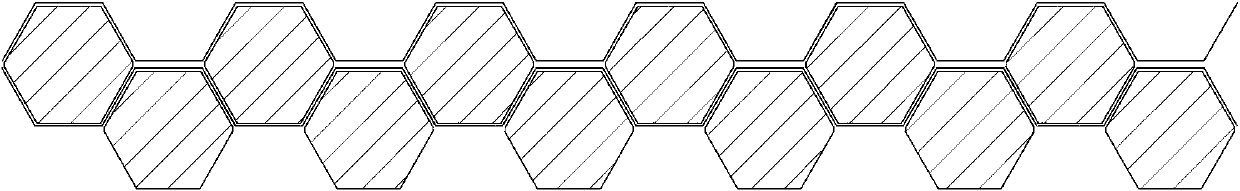

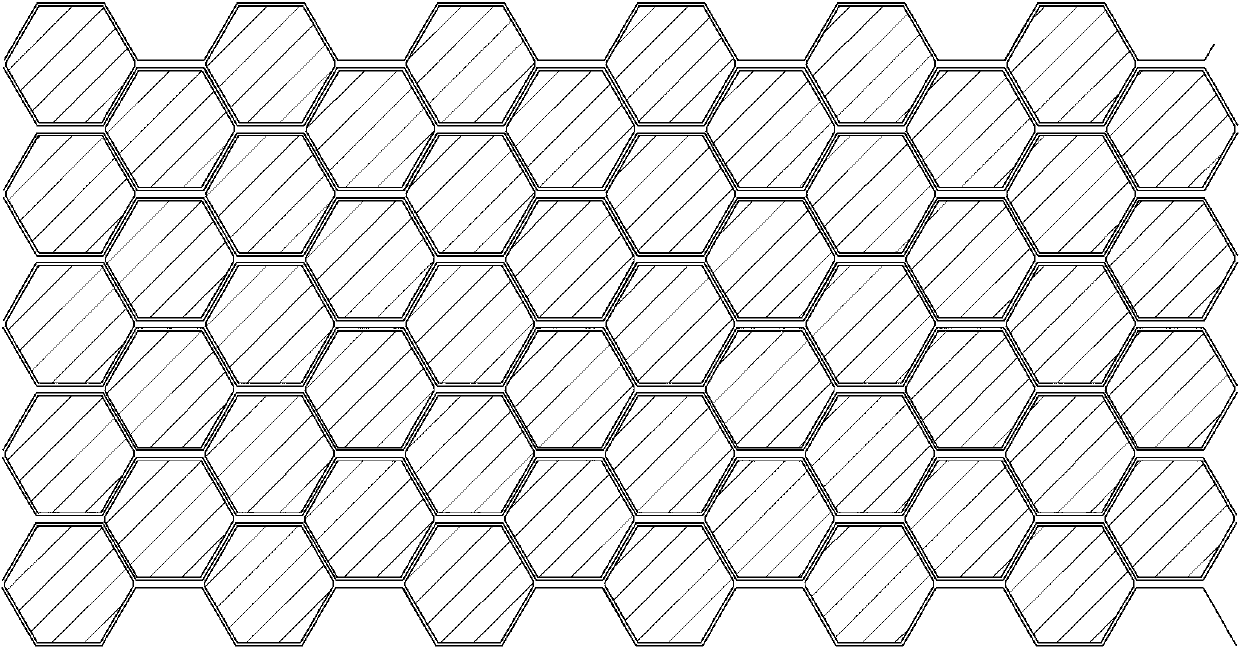

[0032] A hexagonal honeycomb, which comprises a plurality of hexagonal honeycomb units and plastic films arranged on the upper and lower surfaces of the honeycomb units, each honeycomb unit has six side walls with equal lengths, and the vertical distance between the honeycomb units is The two side walls in the direction are not connected, and the remaining four side walls are the side walls shared by two adjacent units. The base material of the honeycomb is polypropylene PP, the height of the honeycomb is 10mm, the diameter of the inscribed circle is 8mm, the thickness of the honeycomb wall is 0.15mm, and the gap between the unconnected side walls of the honeycomb units is 0.1mm.

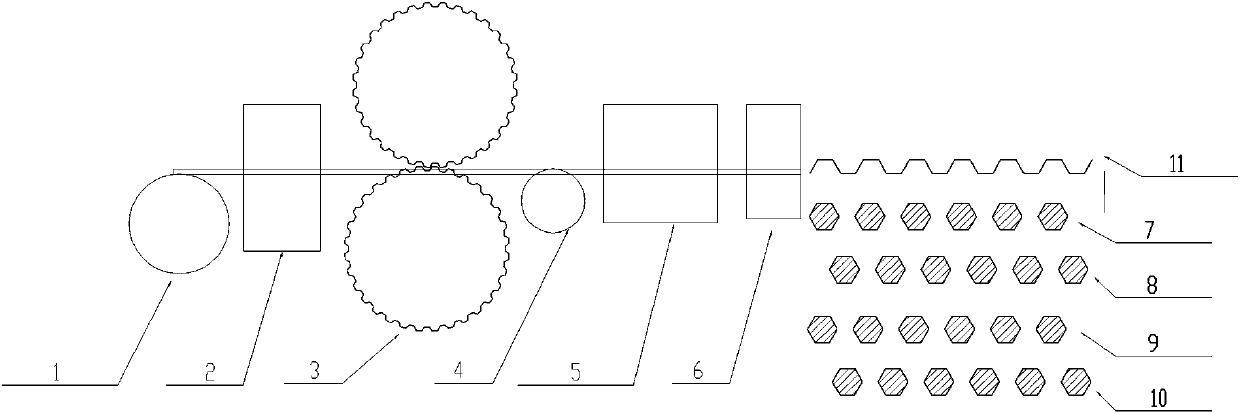

[0033] Its preparation p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com