Oil-gas suspension with volume-variable additional gas chamber and control method of oil-gas suspension

A technology of adding air chambers and oil-air suspensions, applied in suspensions, elastic suspensions, transportation and packaging, etc., can solve the problems of energy consumption of stepper motors, achieve improved shock absorption performance, and wide adjustment range of stiffness and damping , Stiffness and damping adjustment range change effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be described in further detail below in conjunction with the specific embodiments of the accompanying drawings, but the protection scope of the present invention is not limited thereto.

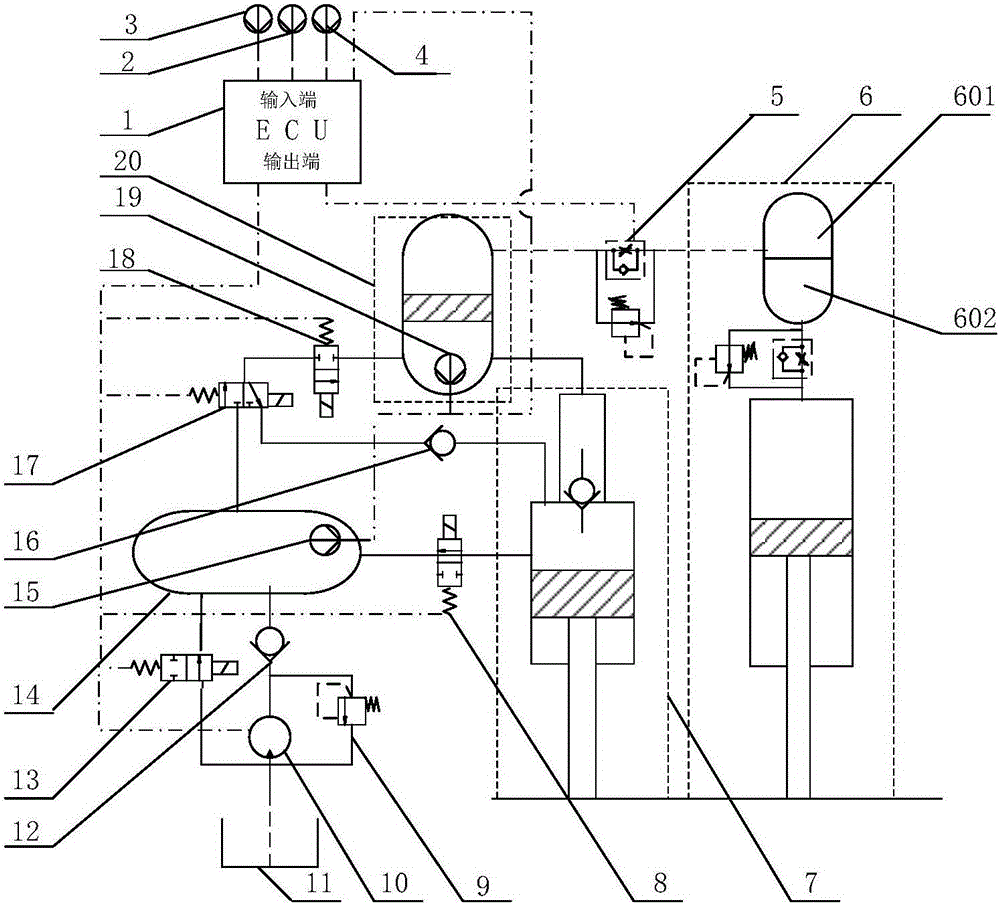

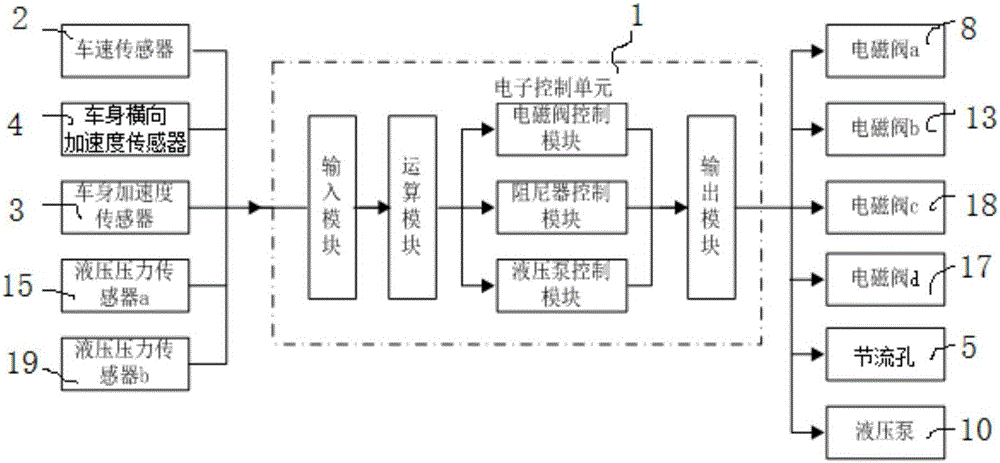

[0036] figure 1 Shown is an embodiment of the oil-pneumatic suspension with variable-volume additional air chambers of the present invention, the oil-pneumatic suspension with variable-volume additional air chambers includes a detection mechanism, an actuator, and an additional air chamber 20 , additional hydraulic cylinder 7, high-pressure oil storage tank 14, oil supply system, oil-pneumatic suspension 6 and electronic control unit 1.

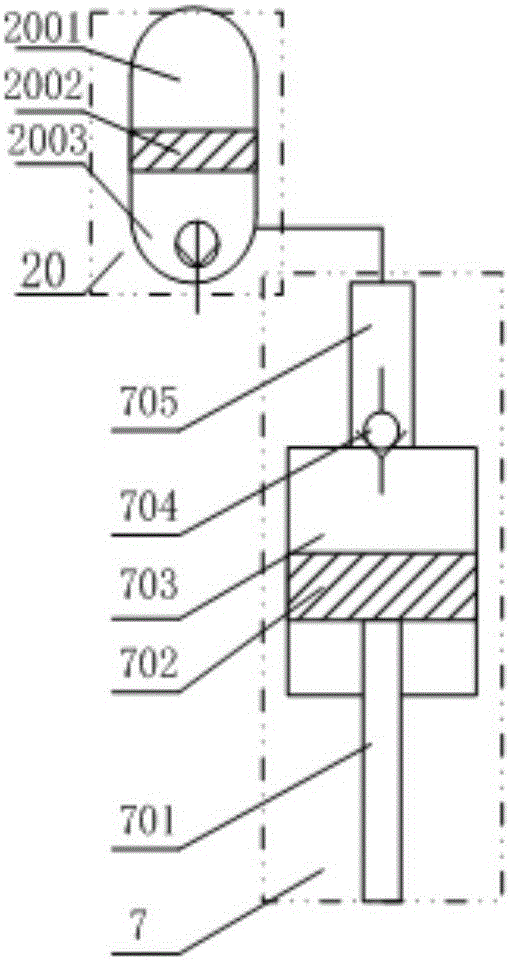

[0037] figure 2 Shown is a schematic diagram of the structure of the additional air chamber and the additional hydraulic cylinder. The additional air chamber 20 is divided into an upper chamber 2001 of the additional air chamber and a lower chamber 2003 of the additional air chamber by the piston a2002; The lower chamber ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com