Automatic rotary box mechanism for cylindrical lithium battery

A lithium battery, cylindrical technology, applied in the direction of conveyors, conveyor objects, transportation and packaging, etc., can solve the problems of batteries that cannot be turned in different directions, high frequency of transfer boxes, short-circuit of batteries, etc., to improve work efficiency and ensure Reliability, reasonable design effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

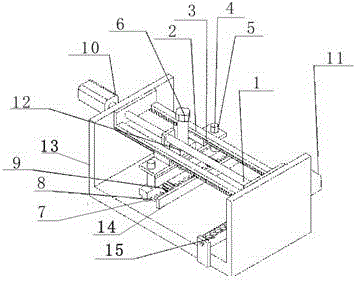

[0038] 1. When the battery material flows to the limit position through the assembly line, at the same time, the limit sensor on the limit block 12 senses the material box and stops running. At the same time, the PLC will turn green at the corresponding IO point. If it is not in place, the PLC will turn on the corresponding IO The dot lights are shown in red.

[0039] 2. After the battery material box is positioned, the servo motor 10 starts to rotate to drive the screw rod 1 and the slider 3 to move to the position set by the program on the slide rail 2, and the upper and lower battery cylinders 6 descend.

[0040] 3. When the upper and lower cylinders 6 of the battery are lowered in place, the limit sensor light is on, and the battery is close to the positioning plate 7.

[0041] When the battery is sucked in, the upper and lower cylinders 6 of the battery rise, and the servo motor 10 drives the screw 1 and the slider 3 to run on the slide rail 2 to the top of the flipping j...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com