Application of self-flocculating Chlorella Minutissima HB-1 in purification of piggery sewage anaerobic effluent

A technology of Chlorella microella and HB-1, applied in biological water/sewage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve the research report on anaerobic effluent purification of pig sewage, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0010] Embodiment 1 The analysis of the culture and the self-flocculation characteristic of tiny chlorella (Chlorella minutissima) HB-1

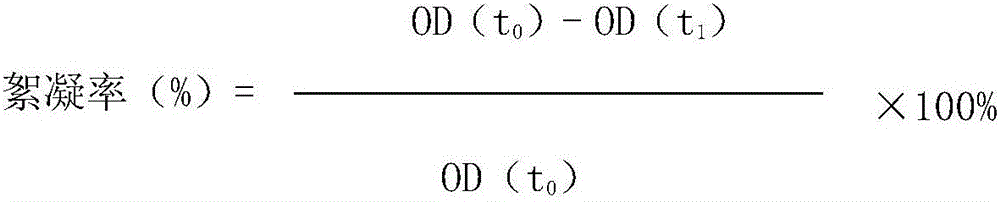

[0011] Pick a small amount of Chlorella minutis HB-1 algae from the vacuum freeze-drying tube, add it to a conical flask filled with 200mL growth medium, light intensity 5000lx, light-dark cycle 12h light / 12h dark, culture at 26°C, every day Shake the flask 2-3 times. After 3-5 days, it can be observed that the color of the culture medium turns green gradually. After growing to the logarithmic growth phase, obtain the seed liquid (algae liquid), measure 80mL of the algae liquid, shake for 30s to mix evenly, absorb 5mL, and immediately measure the OD(t) of the algae liquid at 680nm 0 )value. The rest of the algae liquid was left to stand for 60 minutes, and the algae liquid at the same liquid level was taken to measure the OD(t 1 )value. Three parallel control groups were set up. The self-flocculation (self-sedimentation) activity of the...

Embodiment 2

[0015] Example 2 Domestication test of self-flocculation Chlorella microella HB-1 on anaerobic effluent of pig raising sewage

[0016] Carry out the domestication culture of pig farm sewage anaerobic effluent to Chlorella microella HB-1: take the seed liquid 20mL of Chlorella microella HB-1 of embodiment 1, 8000r / min centrifuge 5min, discard the supernatant to obtain algae, Algae were inoculated into 200mL domestication medium 1 (volume ratio, 10% pig sewage anaerobic effluent+80%H 2 0+10% growth medium (same as embodiment 1)), illuminance 5000lx, light-dark cycle is 12h bright / 12h dark, cultivates at 26 DEG C, shakes Erlenmeyer flask 2~3 times every day, can observe that the culture solution color changes gradually Green, after it grows to the logarithmic phase, it is inoculated into acclimatization medium 2 (volume ratio, 20% pig sewage anaerobic effluent + 70% H 2 O+10% growth medium). Gradually increase the proportion of anaerobic effluent from pig breeding sewage in the...

Embodiment 3

[0017] Example 3 Purification test of self-flocculation Chlorella microella HB-1 on the anaerobic effluent of pig raising sewage

[0018] Take the self-flocculating Chlorella microella HB-1 algae liquid that has been acclimated to tolerate high-concentration anaerobic effluent, and add it to the Erlenmeyer flask filled with 200mL growth medium (same as Example 1) at a volume percentage of 1-2% , illuminance 5000lx, light-dark cycle 12h light / 12h dark, culture at 26°C, shake the Erlenmeyer flask 2-3 times a day, and culture until logarithmic growth phase. Take 50mL algae liquid, centrifuge at 8000r / min for 5min, discard the supernatant to obtain algae. The algae body is connected to 1L treatment solution (40% pig raising sewage anaerobic effluent + 60% H 2 (0, while adding glucose at a mass percentage of 0.1 to 0.3 g / L) as the experimental group, and simultaneously as the blank control group without adding algal bodies, three parallel experiments were set up. The illuminance ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com