Preparation method of flame-retardant rigid polyurethane foam plastic

A polyurethane rigid foam and plastic technology, applied in the field of plastics, can solve the problems of poor thermal stability, high toxicity, and high price of flame retardants

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

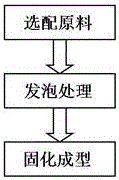

Method used

Image

Examples

Embodiment 1

[0019] The specific preparation method is as follows:

[0020] a) Selected raw materials: in parts by mass, take 100 parts of polyether polyol, 1.5 parts of polyaryl polyisocyanate, 20 parts of composite flame retardant, 2 parts of foam stabilizer B-8462, 1 part of catalyst N, N - Dimethylcyclohexylamine, 0.5 part of surfactant sodium dodecylbenzenesulfonate and 15 parts of blowing agent n-pentane. Among them, the composite flame retardant is composed of ammonium polyphosphate and aluminum hydroxide in a mass ratio of 3:2.

[0021] b) Foaming treatment, the specific preparation process is: first add the weighed polyether polyol, composite flame retardant, foam stabilizer, catalyst, surfactant and foaming agent into a container equipped with a stirring device, Mix evenly with a high-speed mixer; then quickly add the weighed polyaryl polyisocyanate, stir for 30 minutes, and the speed of the mixer is 2000r / min; when there are bubbles and the foam body turns white, immediately in...

Embodiment 2

[0024] The specific preparation method is as follows:

[0025] a) Optional raw materials: in parts by mass, take 100 parts of polyether polyol, 2 parts of polyaryl polyisocyanate, 25 parts of composite flame retardant, 3 parts of foam stabilizer B-8462, 2 parts of catalyst N, N - Dimethylcyclohexylamine, 1 part sodium dodecylbenzenesulfonate surfactant and 20 parts n-pentane blowing agent. Among them, the composite flame retardant is composed of ammonium polyphosphate and aluminum hydroxide in a mass ratio of 3:2.

[0026] b) Foaming treatment, the specific preparation process is: first add the weighed polyether polyol, composite flame retardant, foam stabilizer, catalyst, surfactant and foaming agent into a container equipped with a stirring device, Mix evenly with a high-speed mixer; then quickly add the weighed polyaryl polyisocyanate, stir for 30 minutes, and the speed of the mixer is 2000r / min; when there are bubbles and the foam body turns white, immediately inject the ...

Embodiment 3

[0029] The specific preparation method is as follows:

[0030] a) Selected raw materials: in parts by mass, take 100 parts of polyether polyol, 1.2 parts of polyaryl polyisocyanate, 30 parts of composite flame retardant, 2.5 parts of foam stabilizer B-8462, 1.5 parts of catalyst N, N - Dimethylcyclohexylamine, 0.8 parts of surfactant sodium dodecylbenzenesulfonate and 18 parts of blowing agent n-pentane. Among them, the composite flame retardant is composed of ammonium polyphosphate and aluminum hydroxide in a mass ratio of 3:2.

[0031] b) Foaming treatment, the specific preparation process is: first add the weighed polyether polyol, composite flame retardant, foam stabilizer, catalyst, surfactant and foaming agent into a container equipped with a stirring device, Mix evenly with a high-speed mixer; then quickly add the weighed polyaryl polyisocyanate, stir for 30 minutes, and the speed of the mixer is 2000r / min; when there are bubbles and the foam body turns white, immediat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com