Composite graphite material and application thereof serving as thermal wave transformation material

A composite graphite and heat wave technology, applied in heat exchange materials, chemical industry, chemical instruments and methods, etc., can solve problems such as low efficiency, and achieve the effects of high thermal conductivity, high speed and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

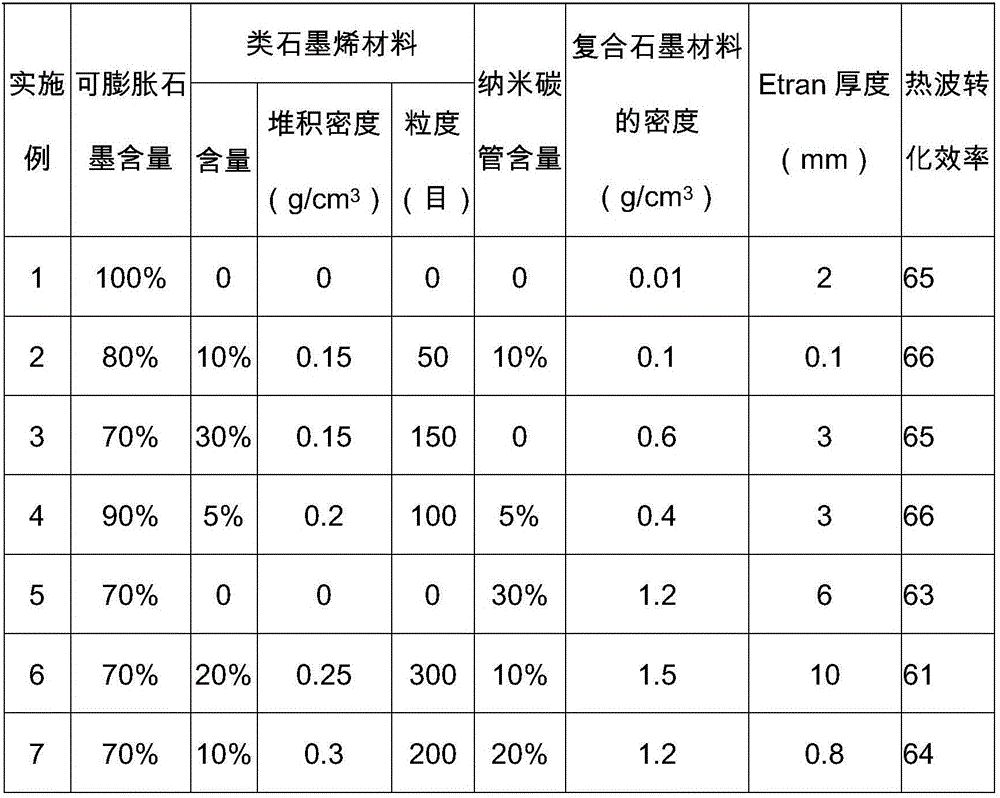

[0020] The present invention will be further described below in conjunction with specific embodiments.

[0021] The components and weight ratios in the following examples were selected for compression molding.

[0022]

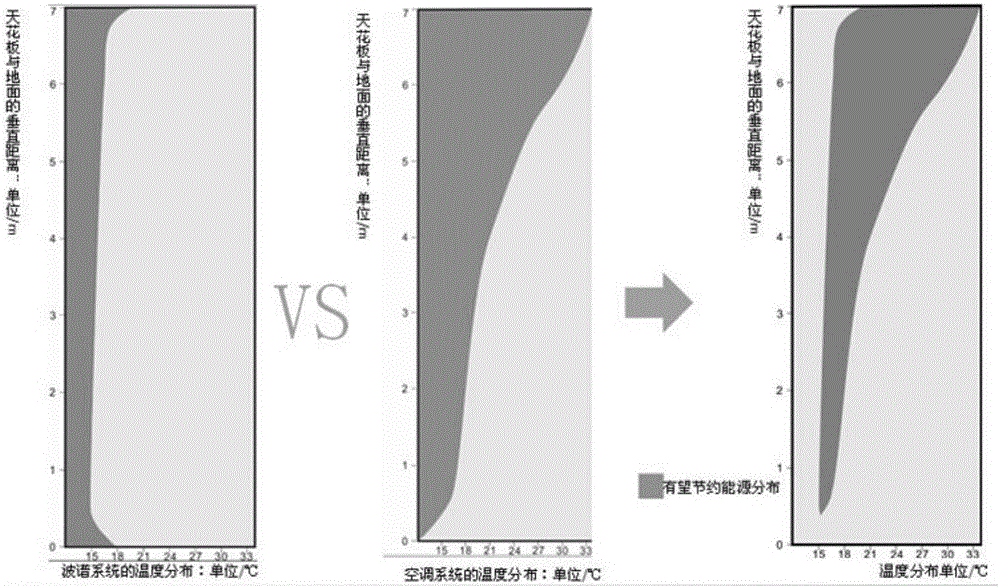

[0023] As can be seen from the above examples, the composite graphite material of the present invention has very high heat wave conversion efficiency. When the composite graphite material is used as a heat wave conversion material, for example, when used as a heat wave conversion ceiling, compared with traditional The system has a good energy-saving effect. See figure 1 , figure 1 The left schematic diagram in the middle is the temperature distribution in the vertical direction in the room when the heat wave conversion ceiling (Popper system) of the present invention is used to work, and the middle schematic diagram is the temperature distribution in the vertical direction in the room when the traditional air-conditioning system is in operation. Compariso...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com