A non-reflux adjustable conical pulp distributor

A pulp distributor and cone-shaped technology, which is applied in the field of backflow-free adjustable conical pulp distributor, can solve the problems that the slurry cannot be evenly distributed across the banner, reduce the power consumption of the sizing system, etc., so that it is not easy to hang the slurry or be blocked, The effect of saving power consumption and precise adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in further detail below in conjunction with the accompanying drawings.

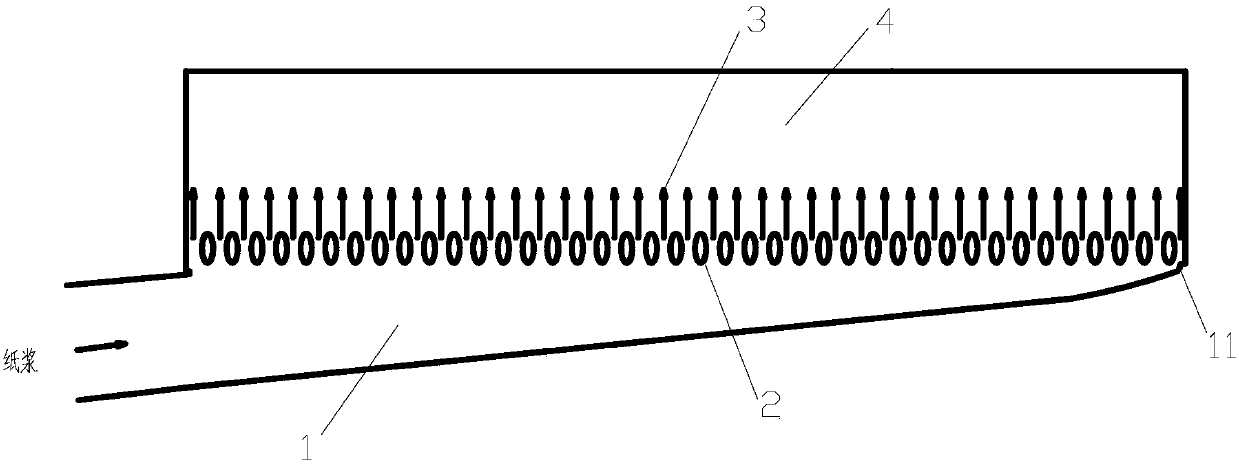

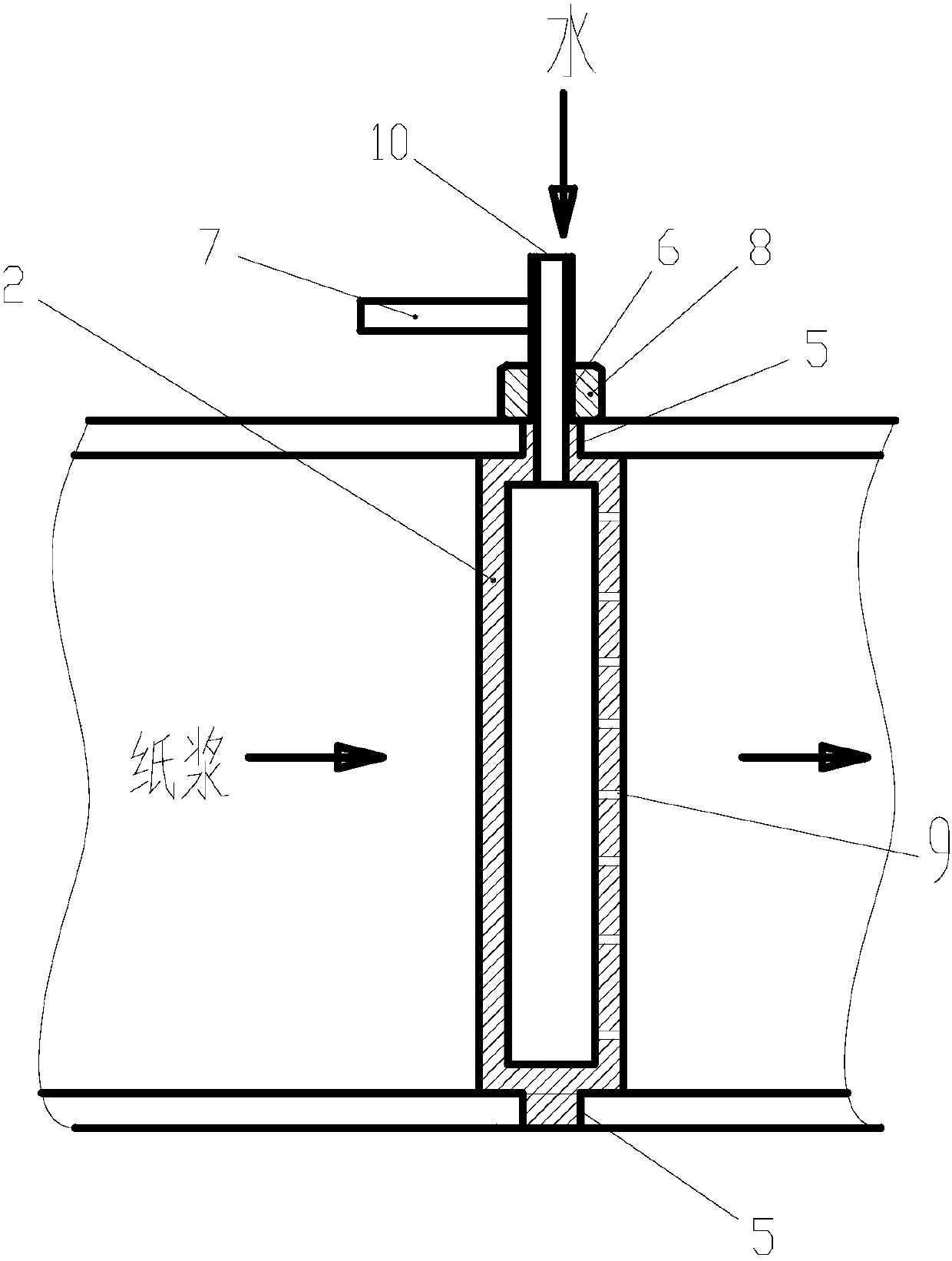

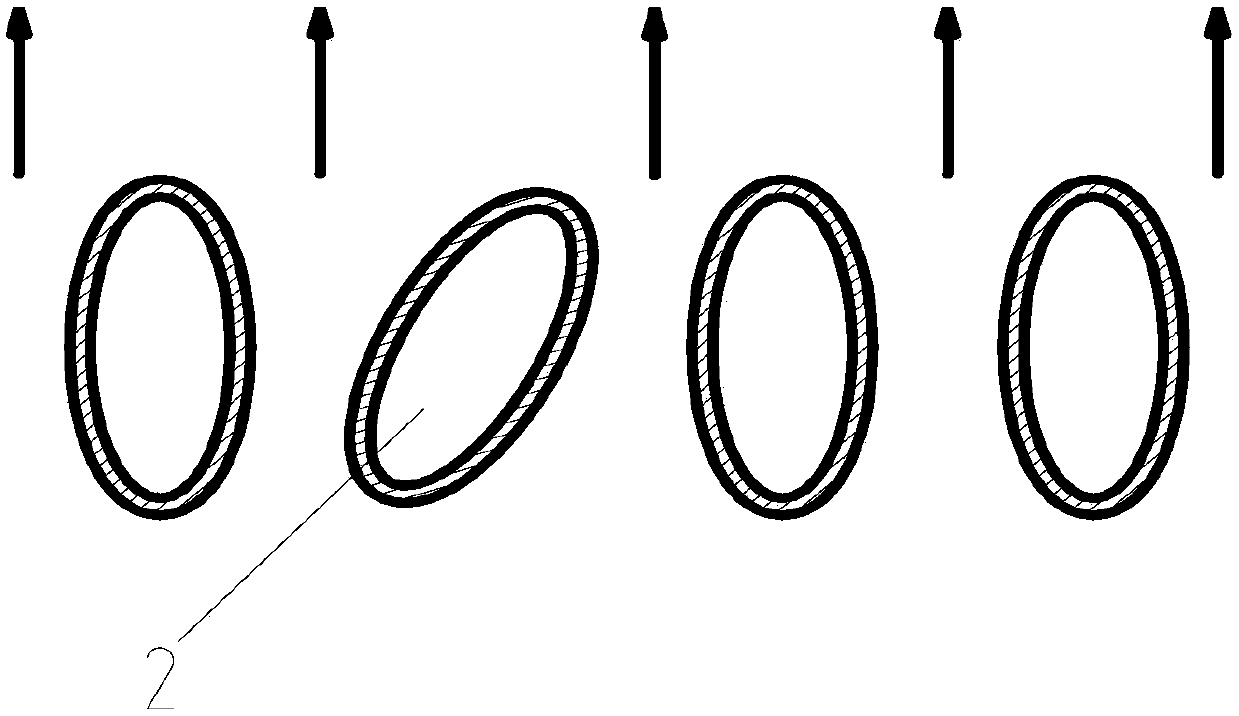

[0025] see figure 1 , figure 2 , the non-reflux adjustable conical slurry distributor provided by the present invention includes a conical main pipe 1, and a number of rotatable and adjustable choke rods 2 are uniformly distributed in the lateral direction of the conical main pipe 1; the inside of the choke rod 2 is a cavity structure, the top of the choke rod 2 has a water inlet 10, and the side wall is provided with a number of water outlet holes 9; the cross section of the choke rod 2 is a non-circular structure; the small end 11 of the tapered main pipe 1 is a closed structure.

[0026] Both ends of the choke rod 2 are fixed in the tapered main pipe 1 through the rotating shaft 5 . The rotating shaft 5 at the upper end of the choke rod 2 is provided with a fastening nut 8; The rotating shaft 5 at the upper end of the choke rod 2 is also connected with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com