Arch rib buckling and hanging installing structure of steel pipe arch bridge

A steel pipe arch bridge and installation structure technology, which is applied in the field of cable-stayed buckle and hanger, can solve the problems of large deformation, high safety risk of steel wire rope sliding, complicated disassembly, etc., and achieve the effect of simple and convenient installation operation, favorable structure and simple structural design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Embodiment of the present invention is described below in conjunction with accompanying drawing, embodiment does not constitute limitation of the present invention:

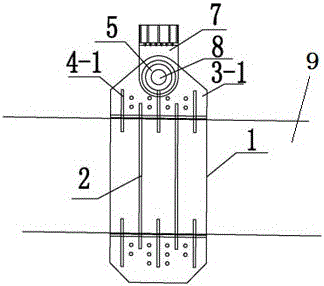

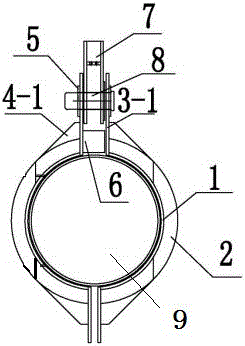

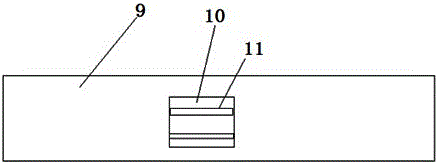

[0021] A steel pipe arch bridge arch rib buckle hanging installation structure, characterized in that the main arch steel pipe of the steel pipe arch bridge is provided with a hoop system, the hoop system includes two symmetrical semicircular hoop units, the semicircular hoop units are arranged on the upper arch rib, and the semicircular The cladding plate wraps the main arch steel pipe directly, and the connecting plate is set on both sides of the semicircular cladding plate to connect the two semicircular hoops with bolts, and the pin hole is set on the connecting plate, and the pin bolt hole connects the anchor box and the hoop through the pin shaft, and the buckle hangs The cables are anchored in the anchor boxes. The substantive technical effect and the realization process of the technical scheme here...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com