A multifunctional rotary excavator

A rotary excavator, multi-functional technology, applied in the direction of earth mover/shovel, mechanically driven excavator/dredger, construction, etc., can solve the problems of rotary drilling tools, landfill, poor project continuity, and impact Project progress and other issues, to achieve the effect of high quality drilled piles, energy saving, and high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

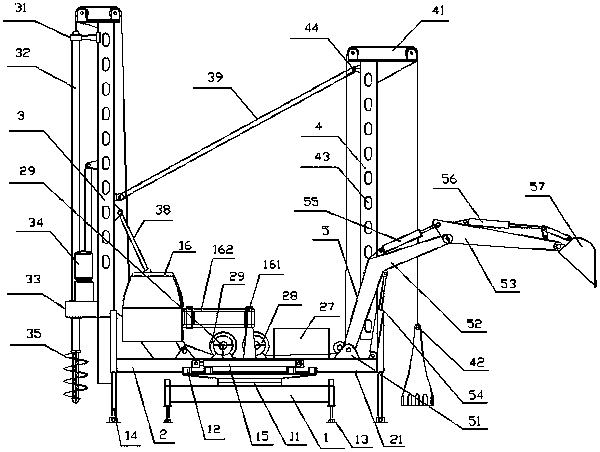

[0050] Example 1: as figure 1 As shown in the figure, when the soft soil layer geology causes the pile hole to collapse during the rotary excavation process, the three-compound soil mixed with sand, stone and soil can be added to the pile hole, and the three-composite soil can be rotated by the hammer installed on the column II4. After the dynamic compaction process becomes a solid layer, the rotary drilling tool is used to drill holes; when encountering rock layer geology, a punching hammer can be installed at the installation end 42, and the free-fall hammer hoist 29 can be started to drive the punching hammer along the After the column II4 rises vertically for a certain distance, the clutch release gear is activated, and the punching hammer falls freely under its own weight to impact the pile hole, perform repeated dynamic ramming, and rush into the rock.

Embodiment 2

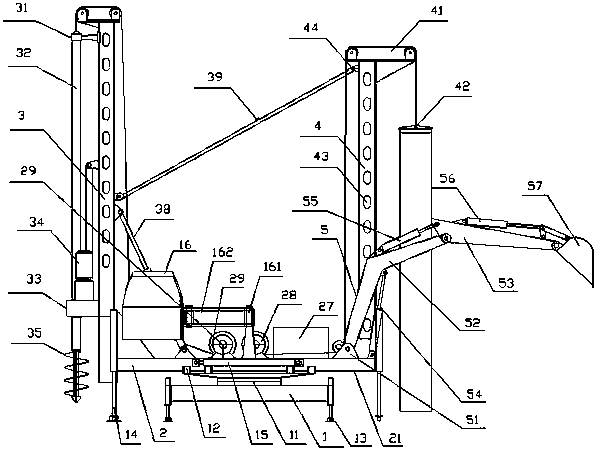

[0051] Example 2: as figure 2 As shown, when the vibrating sinking operation needs to be performed after the pile hole is poured, the vibrating sinking pile is replaced and installed at the installation end 42, and the vibrating sinking pile enters the pile hole vertically downward along the column II4 to perform the vibrating sinking operation of the pile hole.

Embodiment 3

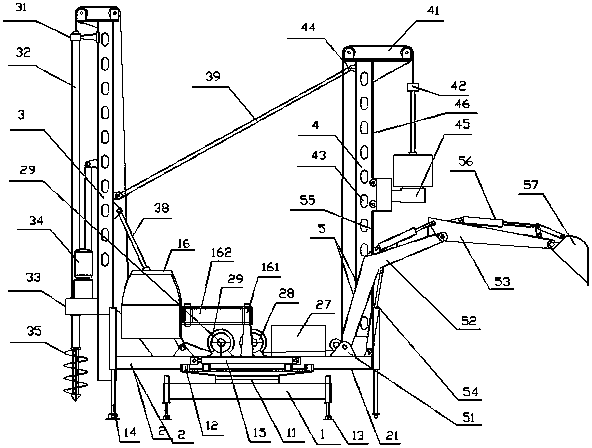

[0052] Example 3: as image 3 , 4 As shown, when a rotary excavation operation is required, a movable assembly table 45 is installed on the sliding guide rail 46, a motor is installed on the upper end of the movable assembly table 45, and the mounting end 42 is also connected to the movable assembly table 45, and the movable assembly table 45 can be installed in the Under the traction of the wire rope, the lifting motion is performed along the sliding guide rail 46; the lower part of the movable assembly table 45 is installed with a long auger pile, and the free-fall hammer hoist 29 and the motor on the movable assembly table 45 are activated, and the long auger pile is vertically along the column II4. Do the rotary drilling operation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com