Anti-impact double-telescopic stand column and application thereof

A double telescopic, impact-resistant technology, applied in pillars/brackets, mining equipment, earthwork drilling and mining, etc., can solve the problems of large hydraulic pressure loss in pump stations, reduce the active initial support force of brackets, and complex liquid supply systems, etc., to achieve High safety, avoid cylinder expansion phenomenon, and improve safety effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

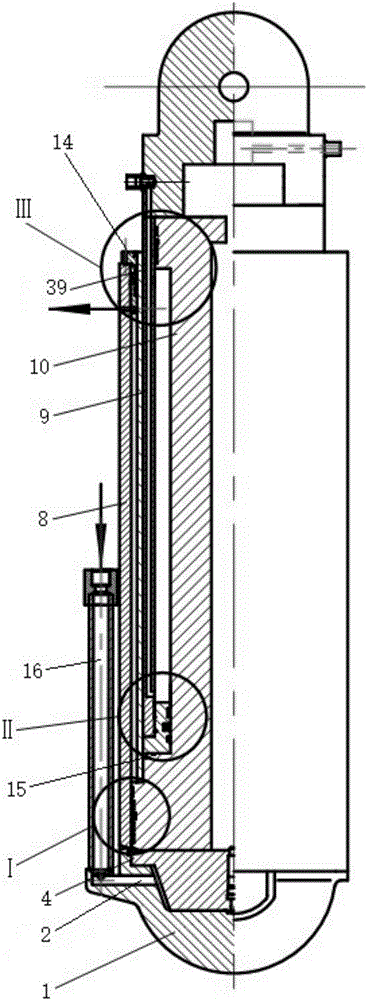

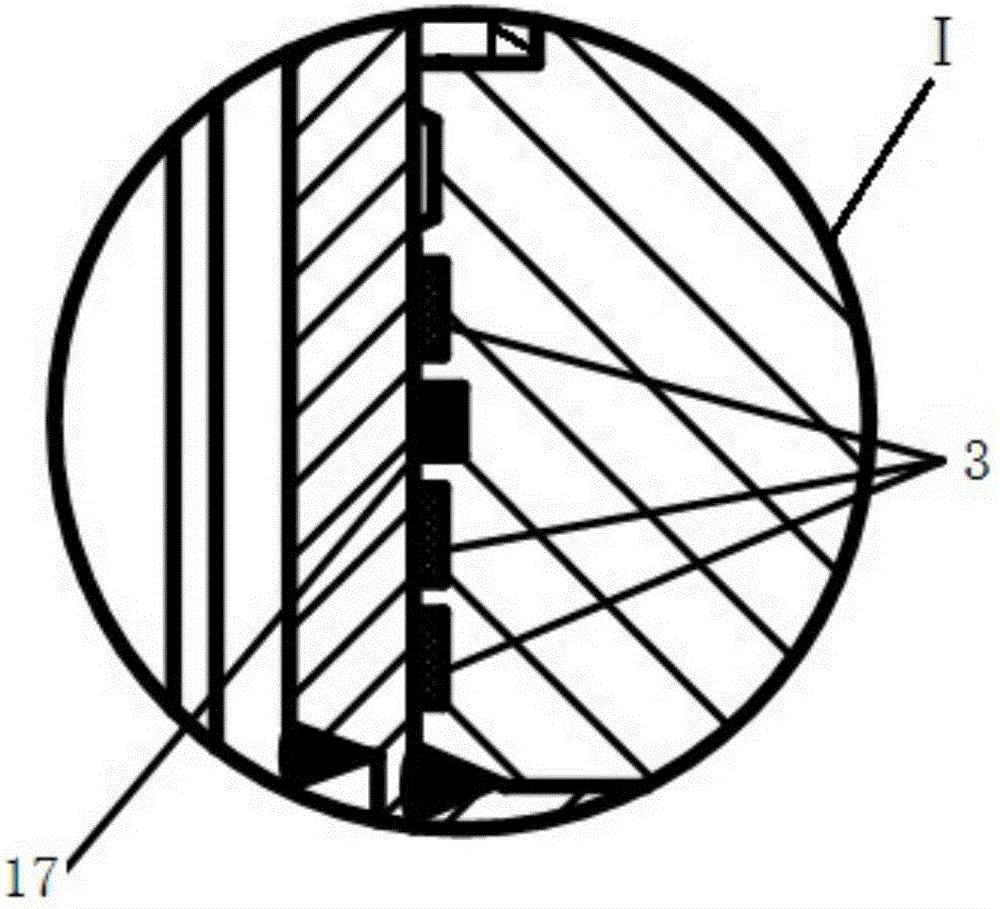

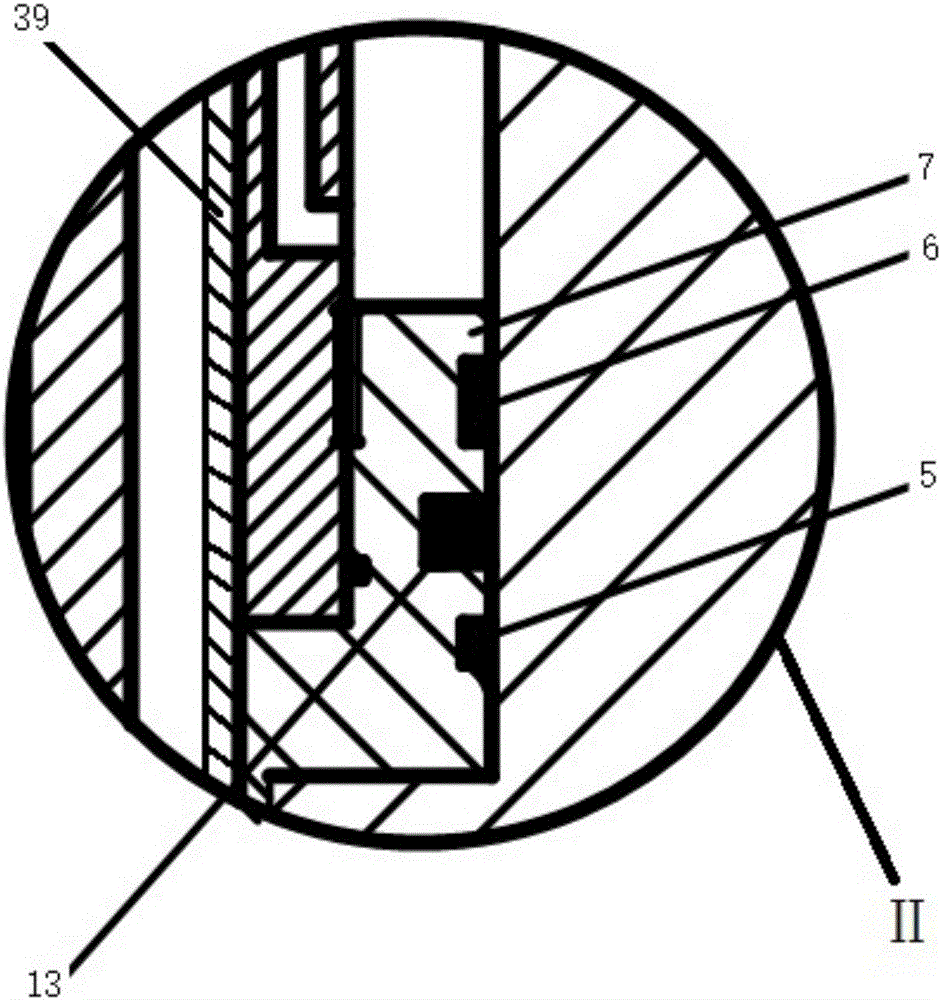

[0041] Such as Figure 1 to Figure 4 As shown, the present embodiment provides an impact-resistant double telescopic column, including a first-stage cylinder 24, an isolation cylinder 39, a movable cylinder 28 and a movable middle rod 10 nested sequentially from outside to inside, and the top of the movable middle rod 10 is provided with an upper Piston 40, bottom end is provided with lower piston 26, and the bottom end of isolation cylinder 39 is welded together with lower piston 26, and upper piston 40 is positioned in movable cylinder 28, and lower piston 26 separates the first-stage cylinder cavity into the first-stage cylinder upper cavity and the lower chamber of the first-stage cylinder, the upper piston 40 separates the inner cavity of the movable cylinder into the upper chamber of the movable cylinder and the lower chamber of the movable cylinder, and the bottom of the first-stage cylinder 24 is provided with a liquid inlet 35 and a safety port connected to the lower c...

Embodiment 2

[0051] Such as Figure 5 As shown, a hydraulic system containing impact-resistant double-telescopic columns includes the impact-resistant double-telescopic columns as described in Embodiment 1, the first spherical shut-off valve 21, the second spherical shut-off valve 20, and the three-position four-way electro-hydraulic reversing Valve 22, hydraulic control one-way valve 23, primary cylinder safety valve 27, anti-expansion safety valve 29, four-position two-way electro-hydraulic reversing valve 31 and movable cylinder safety valve 30; liquid inlet 35 is sequentially connected to hydraulic control one-way valve 23. The three-position four-way electro-hydraulic reversing valve 22, the first spherical stop valve 21 and the liquid inlet pipe 18, the liquid outlet 34 and the liquid return port 33 of the movable cylinder are sequentially connected to the three-position four-way electro-hydraulic reversing valve 22, the second spherical The stop valve 20 and the liquid outlet pipe 1...

Embodiment 3

[0053] A method of using the hydraulic system containing the impact-resistant double telescopic column described in embodiment 2, the process is as follows,

[0054] (1) The process of raising and lowering columns:

[0055] Slow column lift: Open the three-position four-way electro-hydraulic directional valve 22 to the right, the four-position two-way electro-hydraulic directional valve 31 to the left 1 position and the first spherical stop valve 21 on the liquid inlet pipe 18, and the emulsion flows from the liquid inlet pipe 18 enters the lower cavity of the primary cylinder through the first spherical stop valve 21, the three-position four-way electro-hydraulic reversing valve 22, the hydraulic control check valve 23, and the liquid inlet 35 in sequence. At this time, the stroke check valve 25 is not opened. As the pressure of the emulsion rises, the movable middle rod 10 protrudes outward. When the lower piston 26 touches the first-stage cylinder guide sleeve 14, the movab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com