Experimental device used to study the morphology of foam seepage migration process for oil displacement

An experimental device and foam technology are applied in the field of experimental devices for visually studying the migration of foam flooding systems in porous media. It can solve the problems of complex seepage migration, invisible foam structure, and inability to accurately reflect porous media. Convenient customization, low device cost, effective control and effect of changing temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

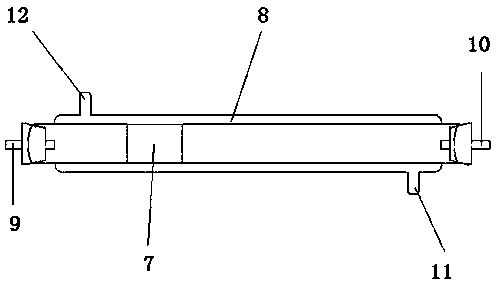

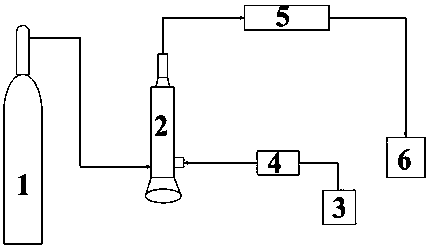

[0022] In this example, participating in figure 1 and figure 2 , an experimental device for studying the shape of the foam seepage migration process for oil displacement. It is mainly composed of a transparent casing 8 and a sand core 7 to form a transparent model pipe device 5 that can observe the macroscopic shape of the foam seepage migration process. The transparent sleeve The tube 8 is made of glass, so that the sand core 7 is set at the set position of the inner cavity of the transparent casing 8, and the inner cavity of the transparent casing 8 is divided into two sections to form a single-layer oil seepage rock formation simulation system. The sand core 7 is made of A piece of G0 type sand chip, the sand core 7 is disc-shaped, the external shape of the sand core 7 is consistent with the inner cavity shape of the transparent sleeve 8, and the external size of the sand core 7 can adapt to the fixed installation of the sand core 7 on the transparent sleeve 8 At the midd...

Embodiment 2

[0029] This embodiment is basically the same as Embodiment 1, especially in that:

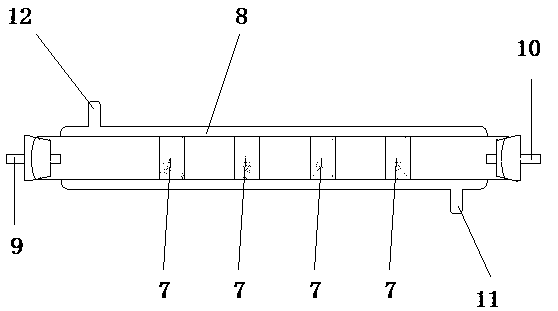

[0030] In this example, see image 3 , in the transparent sleeve 8, the sand core 7 is composed of 4 G0 type sand chips, and multiple sand cores 7 are installed in the transparent sleeve 8 at equal intervals.

[0031] Under the conditions of temperature control at 50°C, normal pressure and total salinity of 30000 mg / L, 500ml of 0.5wt.% α-olefin sodium sulfonate AOS solution prepared in advance was injected into the water source device 3 as simulated formation water, and then Input it into the foam generator 2 through the water pump 4, embed and fix 4 pieces of G0 type sand chips at equal distances in the transparent casing 8, adjust the flow rate of the water pump 4 to inject the formation water into the foam generator 2 to be 6ml / min, and the gas-saving source device 1 The gas flow rate was adjusted to adjust the gas-liquid volume ratio to 2:1, and the test was carried out to observe and reco...

Embodiment 3

[0033] This embodiment is basically the same as the previous embodiment, and the special features are:

[0034] In this example, participating in Figure 4, in the transparent sleeve 8, the sand core 7 is composed of 3 sand chips, which are G0, G1, and G2 type sand chips respectively, and multiple sand cores 7 are installed in the transparent sleeve 8 at equal intervals.

[0035] Under the conditions of room temperature, normal pressure and 30000 mg / L total salinity, 500ml of the pre-configured compound formula solution with a total concentration of 0.5wt.% is injected into the water source device 3 as simulated formation water, and then input through the water pump 4 Into the foam generator 2, embed and fix G0, G1, G2 type sand chips at equal distances in the model tube, adjust the flow rate of the water pump 4 to inject formation water into the foam generator 2 to 6ml / min, and the gas delivery rate of the gas-saving source device 1 , adjust the gas-liquid volume ratio to 2:...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com