Ionic type rare earth in-situ mineral leaching anti-crack and anti-seepage grouting material and preparation method thereof

An ionic rare earth and grouting material technology, applied in mining equipment, earthwork drilling, shaft equipment, etc., can solve problems such as bedrock floor crack leakage, soil and water pollution, waste of rare earth resources, etc., to improve the density and strength, long storage time, fine particle size and easy dispersion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

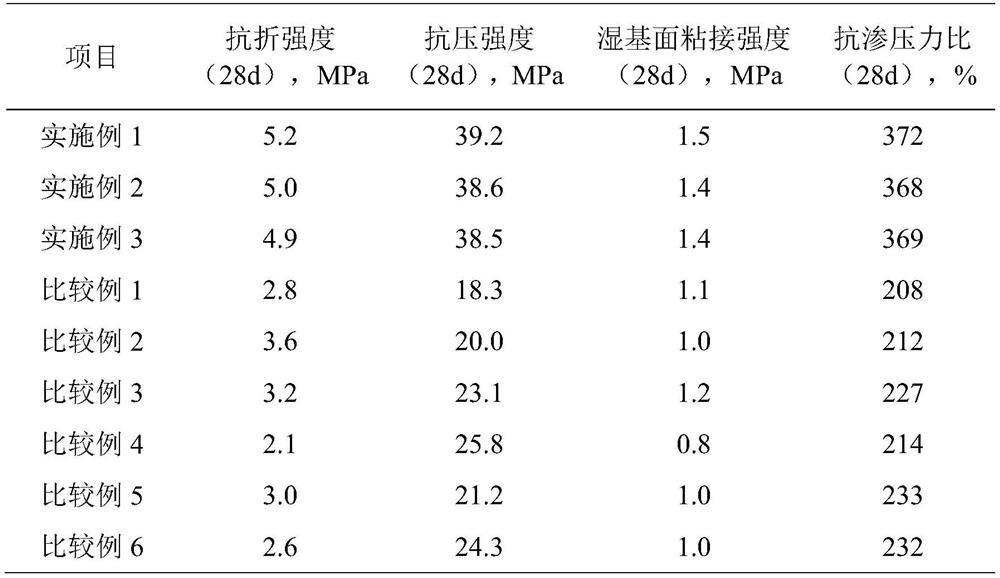

Embodiment 1

[0023] An ionic rare earth in-situ leaching anti-cracking and anti-seepage grouting material is composed of the following components in parts by weight: 40 parts of waste tailings fine waste residue powder, 15 parts of fly ash, fine ore powder (nano silicon dioxide powder) 25 parts, 30 parts of water-based epoxy resin emulsion, 4 parts of activator (solid sodium methyl silicate, particle size 150 mesh) and 2.5 parts of activator;

[0024] Wherein, the activator is water glass whose modulus is adjusted at 1.6±0.1, and its solid content is 38%.

[0025] The preparation method of the above-mentioned ionic rare earth in-situ leaching anti-cracking and anti-seepage grouting material comprises the following steps:

[0026] Step 1: After grinding and activating the fine waste slag and fly ash of waste tailings, add fine ore powder and activator, stir evenly, then heat to 180°C for activation, and cool for later use;

[0027] In step 2, the water-based epoxy resin emulsion and the ac...

Embodiment 2

[0029] An ionic rare earth in-situ leaching anti-cracking and anti-seepage grouting material is composed of the following components in parts by weight: 50 parts of waste tailings fine waste residue powder, 10 parts of fly ash, fine ore powder (nano silicon dioxide powder) 30 parts, 20 parts of water-based epoxy resin emulsion, 5 parts of activator (solid sodium methyl silicate, particle size 200 mesh) and 2 parts of activator;

[0030] Wherein, the activator is water glass whose modulus is adjusted at 2.1±0.1, and its solid content is 32%. .

[0031] The preparation method of the above-mentioned ionic rare earth in-situ leaching anti-cracking and anti-seepage grouting material comprises the following steps:

[0032] Step 1: After grinding and activating the fine waste residue and fly ash of waste tailings, add fine ore powder and activator, stir evenly, then heat to 200°C for activation, and cool for later use;

[0033] In step 2, the water-based epoxy resin emulsion and th...

Embodiment 3

[0035] An ionic rare earth in-situ leaching anti-cracking and anti-seepage grouting material is composed of the following components in parts by weight: 30 parts of waste tailings fine waste residue powder, 20 parts of fly ash, and 20 parts of fine ore powder (nano calcium carbonate powder) parts, 40 parts of water-based epoxy resin emulsion, 3 parts of activator (solid sodium methyl silicate, particle size 100 mesh) and 3 parts of activator;

[0036] Wherein, the activator is water glass whose modulus is adjusted at 1.2±0.1, and its solid content is 45%.

[0037] The preparation method of the above-mentioned ionic rare earth in-situ leaching anti-cracking and anti-seepage grouting material comprises the following steps:

[0038] Step 1: After grinding and activating the fine waste residue and fly ash of waste tailings, add fine ore powder and activator, stir evenly, then heat to 160°C for activation, and cool for later use;

[0039] In step 2, the water-based epoxy resin emu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com