Determination method of aroma components in electronic cigarette aerosol

A technology for aroma components and measurement methods, applied in the field of analysis and measurement, can solve the problems of lack of quality control of electronic cigarettes, lack of measurement and analysis methods of volatile aroma components of electronic cigarette aerosols, lack of comprehensive understanding, etc. The effect of expansion, saving analysis cost, and low detection limit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

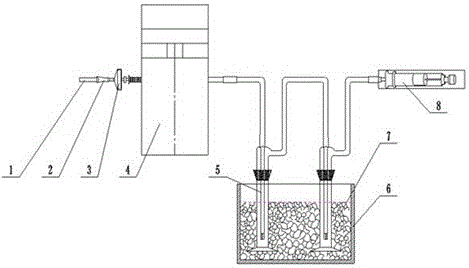

[0034] The trapping device that the present invention adopts is as figure 1 As shown, put the 44 mm Cambridge filter into the filter holder, the rough side of the filter should face the incoming flue gas, close the filter holder and check that it is properly assembled. If the e-cigarette can be put into one end of the trap during the smoking process, and there is no air leakage, then directly insert the e-cigarette into the trap for puffing. But now commercially available electronic cigarette nozzles have different shapes. If one end of the trap does not match the electronic cigarette nozzle and air leakage occurs during the suction process, it is necessary to add a good airtight adapter between the trap and the electronic cigarette. , to prevent air leakage during suction.

[0035] Two 30mL dichloromethane absorption bottles are connected in series between the smoking machine trap and the suction syringe, and the absorption bottles are put into the heat preservation barrel f...

Embodiment 2

[0052] The trapping device that the present invention adopts is as figure 1 As shown, put the 44 mm Cambridge filter into the filter holder, the rough side of the filter should face the incoming flue gas, close the filter holder and check that it is properly assembled. If the e-cigarette can be put into one end of the trap during the smoking process, and there is no air leakage, then directly insert the e-cigarette into the trap for puffing. But now commercially available electronic cigarette nozzles have different shapes. If one end of the trap does not match the electronic cigarette nozzle and air leakage occurs during the suction process, it is necessary to add a good airtight adapter between the trap and the electronic cigarette. , to prevent air leakage during suction.

[0053] Between the smoking machine trap and the suction syringe, there are two 40mL dichloromethane absorbing bottles connected in series. The absorbing bottles are placed in an insulated barrel for ice-...

Embodiment 3

[0067] The trapping device that the present invention adopts is as figure 1 As shown, put the 44 mm Cambridge filter into the filter holder, the rough side of the filter should face the incoming flue gas, close the filter holder and check that it is properly assembled. If the e-cigarette can be put into one end of the trap during the smoking process, and there is no air leakage, then directly insert the e-cigarette into the trap for puffing. But now commercially available electronic cigarette nozzles have different shapes. If one end of the trap does not match the electronic cigarette nozzle and air leakage occurs during the suction process, it is necessary to add a good airtight adapter between the trap and the electronic cigarette. , to prevent air leakage during suction.

[0068] Between the smoking machine trap and the suction syringe, there are two 40mL dichloromethane absorbing bottles connected in series. The absorbing bottles are placed in an insulated barrel for ice-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| ionization potential | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com