A gate driving unit, a row gate scanning driver and a driving method thereof

A gate drive and row gate technology, applied in the direction of instruments, static indicators, etc., can solve the problems of reducing circuit switching speed, complex circuit structure, and increased internal wiring, so as to reduce power consumption, improve circuit efficiency, reduce Effect of Clock Voltage Swing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

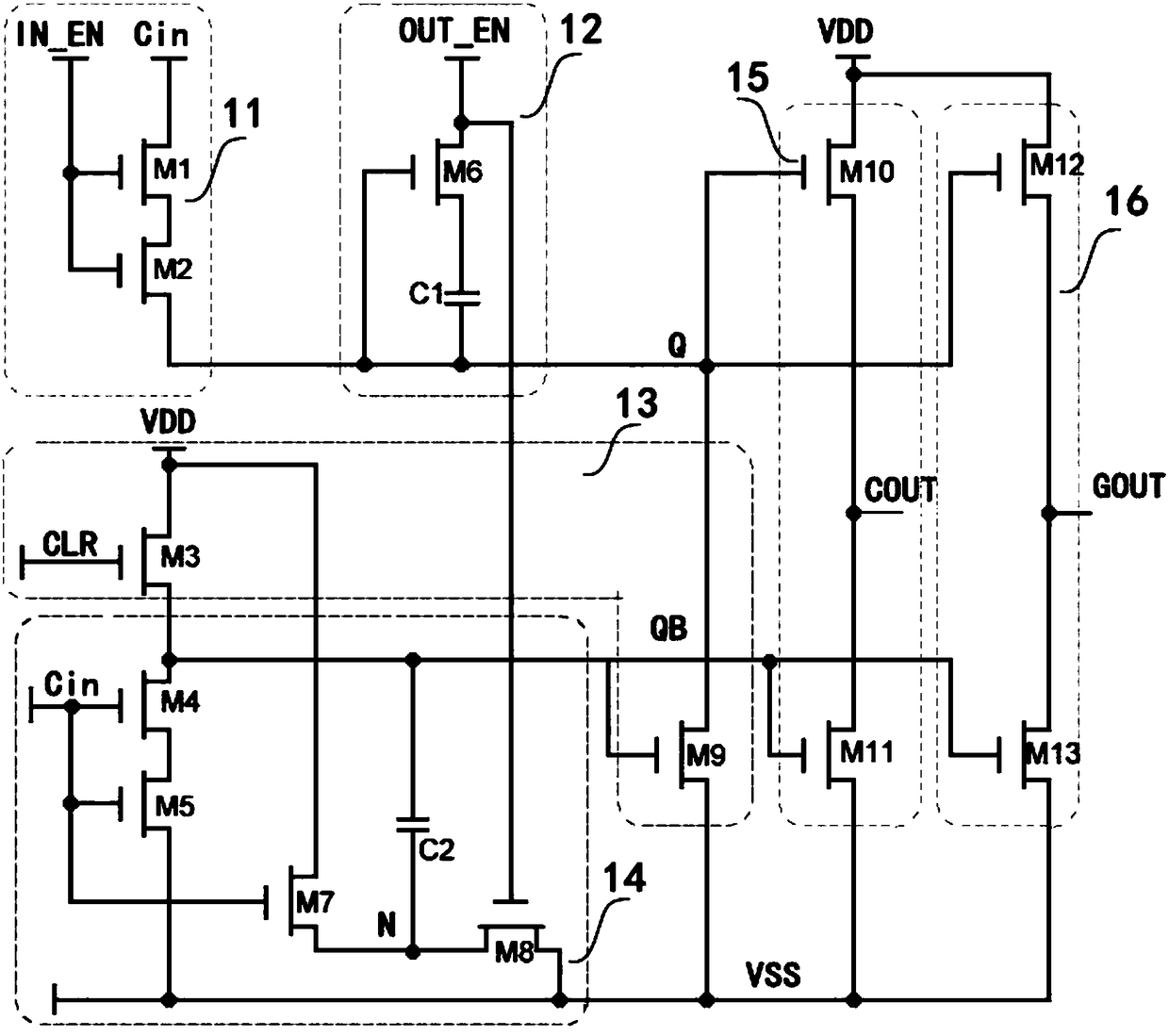

[0042] Such as figure 1 As shown, a gate drive unit is composed of a signal acquisition module 11, a boost module 12, an inverter module 13, a negative pressure module 14, an internal output module 15 and a scan output module 16. The gate drive unit The control signal includes the first clock input port IN_EN, the second clock input port OUT_EN, the third clock input port CLR, the first power port VDD, the second power port VSS, the signal collection port Cin, the first output port COUT and the second output port port GOUT;

[0043] The signal acquisition module 11 is composed of first and second transistors. The drain of the first transistor M1 is connected to the signal acquisition port Cin, its source is connected to the drain of the second transistor M2, and its gate is connected to the second transistor M2 respectively. The gate of is connected to the first clock input port IN_EN;

[0044] The boost module 12 is composed of a sixth transistor M6 and a first storage capa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com