LVDS cable for automobile wire

A technology of cables and wires, applied in the field of LVDS cables for automotive wires, can solve the requirements of information transmission that is not suitable for higher speed and higher quality, the characteristics of transmission are prone to various problems, and the source of signal interference in the car is complex, etc. problems, to achieve the effects of not easy to deform, moisture resistance, and improve strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

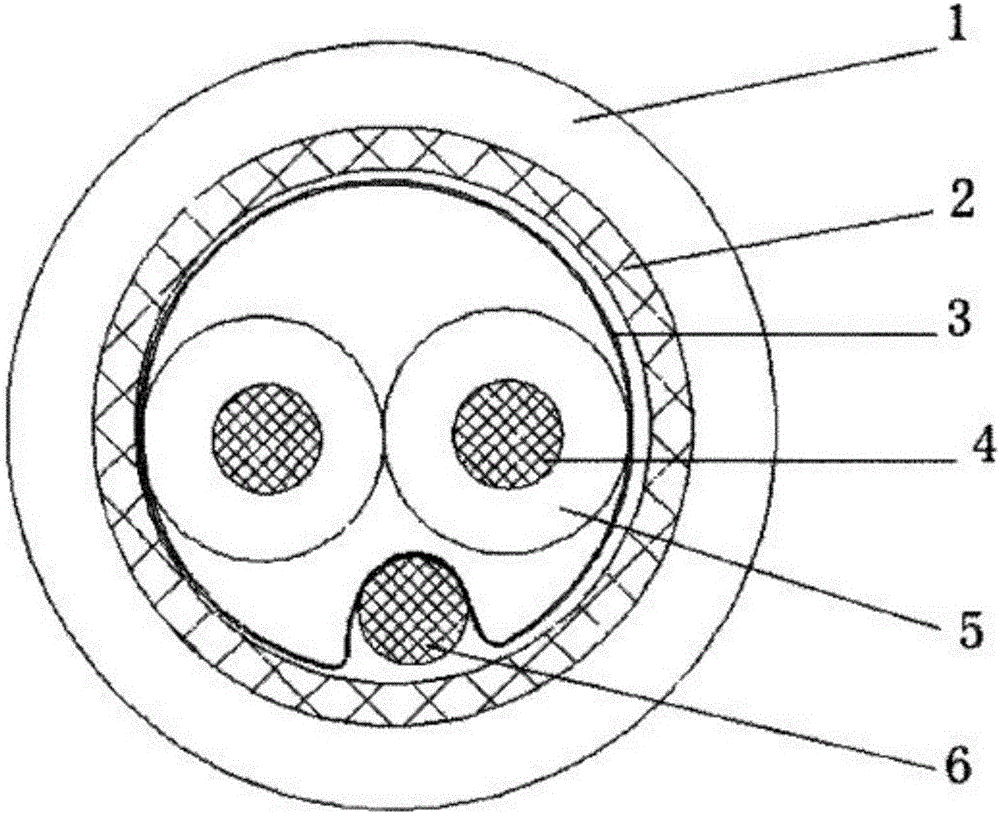

[0068] An LVDS cable for automotive wires, comprising a sheath layer 1, a braid layer 2, an aluminum foil layer 3, a conductor 4, and a ground wire 6. The conductors 4 are respectively wrapped with an insulating layer 5, and the insulating layer 5 is wrapped with aluminum foil Layer 3, the ground wire 6 is sandwiched between the aluminum foil layer 3 and the braid layer 2, and the sheath layer 1 is wrapped outside the braid layer 2; the thickness of the sheath layer 1 is 0.7mm, and the braid The thickness of the object layer 2 is 0.4 mm, and the thickness of the insulating layer 5 is 0.5 mm.

[0069] Among them, the composition and weight percentage of the aluminum foil material of the aluminum foil layer are: Si: 0.10%, Fe: 0.05%, Cu: 0.20%, Mn: 0.90%, Mg: 0.03%, Zn: 0.005%, Ti: 0.03%, B : 0.02%, Y: 0.04%, Ce: 0.03%, Al balance and inevitable impurities.

[0070] The material of the sheath layer includes the following components and their weight parts: polytetrafluoroethylene: 60...

Embodiment 2

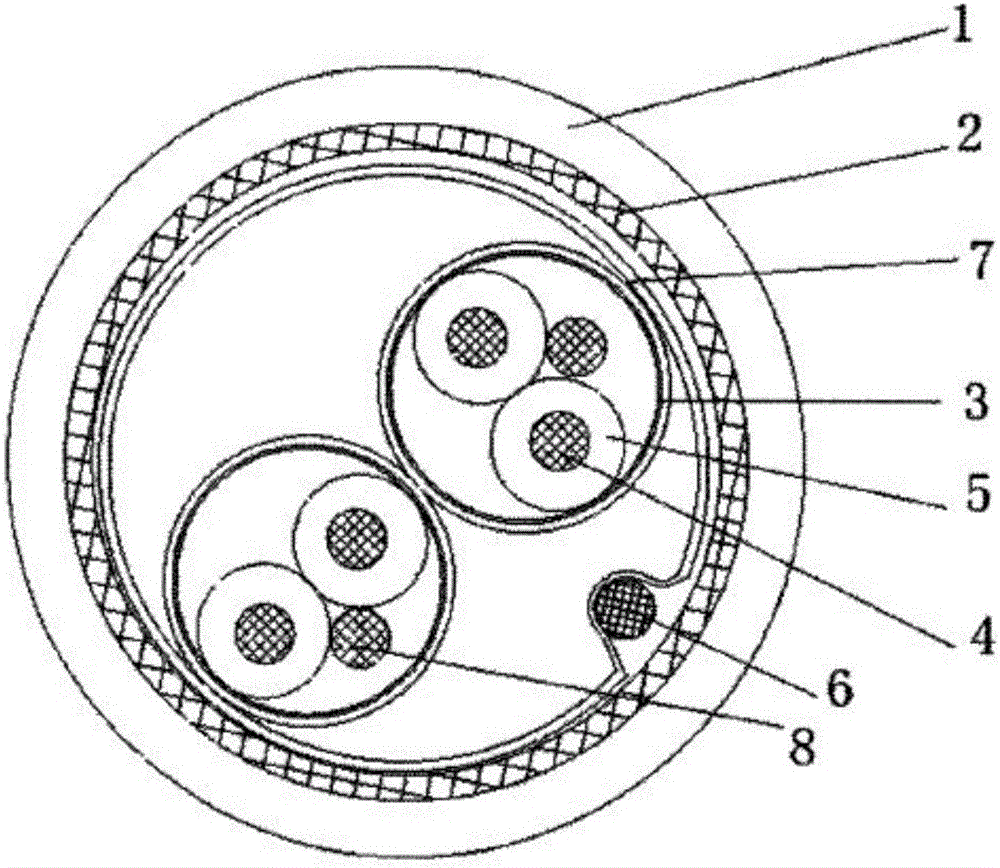

[0077] An LVDS cable for automotive wires, comprising a sheath layer 1, a braid layer 2, an aluminum foil layer 3, a conductor 4, a ground wire 6, a Mylar tape layer 7 and a second ground wire 8. The conductors 4 are respectively insulated Each pair of conductors 4 together with the outside of the second ground wire 8 are respectively wrapped with an aluminum foil layer 3, an aluminum foil layer 3 is wrapped outside the insulating layer 5, and a Mylar tape layer 7 is also wrapped on the outside 3 of the aluminum foil layer. The drawstring layer 7 is located between the aluminum foil layer 3 and the braid layer 2, and the ground wire 6 is sandwiched between the Mylar tape layer 7 and the braid layer 2, and the sheath layer 1 is wrapped outside the braid layer 2; The thickness of the sheath layer is 0.7 mm, the thickness of the braid layer is 0.4 mm, and the thickness of the insulating layer is 0.6 mm.

[0078] Among them, the composition and weight percentage of the aluminum foil ...

Embodiment 3

[0086] An LVDS cable for automotive wires, comprising a sheath layer 1, a braid layer 2, an aluminum foil layer 3, a conductor 4, and a ground wire 6. The conductors 4 are respectively wrapped with an insulating layer 5, and the insulating layer 5 is wrapped with aluminum foil Layer 3, the ground wire 6 is sandwiched between the aluminum foil layer 3 and the braid layer 2, and the sheath layer 1 is wrapped outside the braid layer 2; the thickness of the sheath layer 1 is 0.6 mm, and the braid The thickness of the object layer 2 is 0.3 mm, and the thickness of the insulating layer 5 is 0.4 mm.

[0087] Among them, the composition and weight percentage of the aluminum foil material of the aluminum foil layer are: Si: 0.05%, Fe: 0.08%, Cu: 0.10%, Mn: 1.20%, Mg: 0.02%, Zn: 0.008%, Ti: 0.02%, B : 0.05%, Y: 0.02%, Ce: 0.05%, Al balance and inevitable impurities.

[0088] The material of the sheath layer includes the following components and their weight parts: polytetrafluoroethylene: 5...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com