Agricultural composite film

A composite film and urea technology, applied in the field of plastic film, can solve the problems of increasing farmers' manpower and material resources, plastic film is not resistant to pulling, affecting the use of plastic film, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

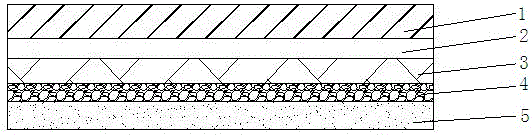

[0021] Such as figure 1 As shown, figure 1 It is a schematic diagram of the structure of an agricultural composite film provided by the present invention, which is sequentially arranged from top to bottom: a polytetrafluoroethylene layer 1, an anti-aging layer 2, a reinforcement layer 3, an insulation layer 4 and a urea sustained-release layer 5; The weight parts of the components in the urea sustained-release layer 5 are: polyvinyl alcohol: 65%; urea: 25%; formaldehyde: 8%; antioxidant: 0.5%; surfactant: 1.5%. The thickness of the composite film is 1.5 mm.

[0022] The reinforcing layer 3 is a grid formed by multiple fibers, and the polytetrafluoroethylene layer 1, the anti-aging layer 2, the reinforcing layer 3, the thermal insulation layer 4, and the urea sustained-release layer 5 are bonded together by thermal composite , The antioxidant is antioxidant 1010, and the surfactant is an anionic surfactant.

Embodiment 2

[0024] An agricultural composite film, which is sequentially arranged from top to bottom: a polytetrafluoroethylene layer 1, an anti-aging layer 2, a reinforcing layer 3, an insulation layer 4, and a urea sustained-release layer 5; wherein, the urea sustained-release layer 5 is The weight parts of each component are: polyvinyl alcohol: 70%; urea: 18%; formaldehyde: 5%; antioxidant: 1%; surfactant: 5%, and the thickness of the agricultural composite film is 2.5 mm.

[0025] The reinforcing layer 3 is a grid formed by multiple fibers, and the polytetrafluoroethylene layer 1, the anti-aging layer 2, the reinforcing layer 3, the thermal insulation layer 4, and the urea sustained-release layer 5 are bonded together by thermal composite , The antioxidant is antioxidant 1010, and the surfactant is an anionic surfactant.

Embodiment 3

[0027] An agricultural composite film, which is sequentially arranged from top to bottom: a polytetrafluoroethylene layer 1, an anti-aging layer 2, a reinforcing layer 3, an insulation layer 4, and a urea sustained-release layer 5; wherein, the urea sustained-release layer 5 is The weight parts of each component are: polyvinyl alcohol: 73%; urea: 17%; formaldehyde: 6.5%; antioxidant: 0.5%; surfactant: 3%, and the thickness of the agricultural composite film is 3.5 mm.

[0028] The reinforcing layer 3 is a grid formed by multiple fibers, and the polytetrafluoroethylene layer 1, the anti-aging layer 2, the reinforcing layer 3, the thermal insulation layer 4, and the urea sustained-release layer 5 are bonded together by thermal composite The antioxidant is antioxidant 168, and the surfactant is a nonionic surfactant.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com