Okra polysaccharide beverage and preparation method thereof

A polysaccharide and beverage technology, applied in food preparation, application, food science and other directions, can solve the problems of difficult standardization and compounding, not many, insufficient utilization of nutrients, etc., to promote greening and ecological environment protection, easy to promote , significant social and economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

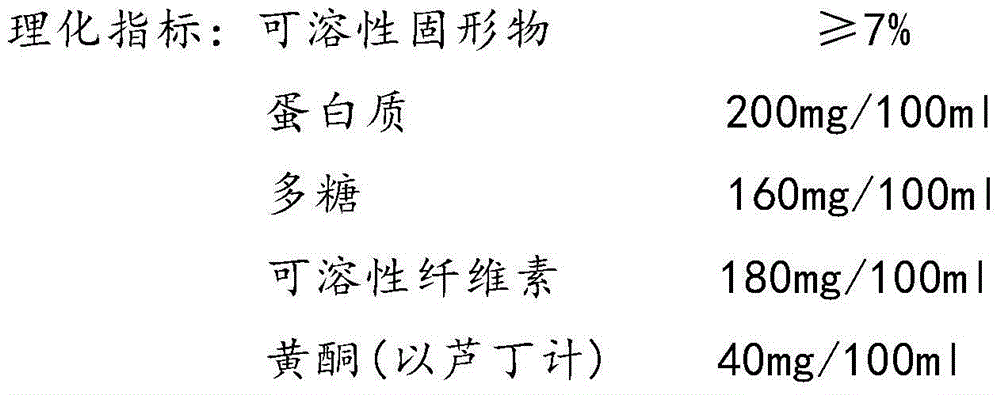

Embodiment 1

[0034] (1) A kind of okra polysaccharide beverage and preparation method thereof:

[0035] Okra juice 100%, white sugar 60g / L, sucralose 0.3g / L, xylitol 5g / L, citric acid 0.5g / L, tartaric acid 0.1g / L, sodium citrate 0.1g / L, honey 0.3g / L, salt 1g / L, sodium isovitamin C 1g / L, pectin 1g / L, sodium alginate 1g / L, sodium copper chlorophyllin 6mg / L.

[0036] process, method

[0037] Process flow: Ripe okra fruit→cleaning→stalk removal→precooking→beating→filtering→compounding→homogenizing→sterilizing→okra polysaccharide drink.

[0038] 1. Select mature, fresh, crisp and tender okra fruits to wash, remove the stems and trim, use a mixture of 0.1-0.5g / L zinc chloride and copper sulfate, and blanch at 85-95°C for 2-3 minutes. cool down.

[0039] 2. Make pulp according to the ratio of fruit to water 1:10, the soluble solid content in the pulp is 4%, and filter.

[0040] 3. Use whole okra juice as raw material, supplemented with stabilizer pectin, sodium alginate; sweetener white sugar...

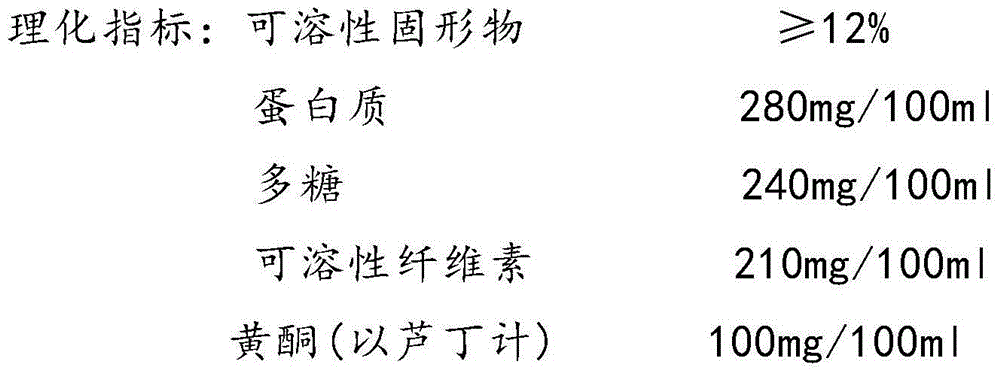

Embodiment 2

[0047] (1) A kind of okra polysaccharide beverage and preparation method thereof:

[0048] Okra juice 100%, white sugar 100g / L, sucralose 0.1g / L, xylitol 2g / L, citric acid 1g / L, tartaric acid 0.5g / L, sodium citrate 0.3g / L, honey 0.1 g / L, salt 2g / L, sodium isovitamin C 2g / L, pectin 3g / L, sodium alginate 0.5g / L, sodium copper chlorophyllin 15mg / L.

[0049]process, method

[0050] Process flow: Ripe okra fruit→cleaning→stalk removal→precooking→beating→filtering→compounding→homogenizing→sterilizing→okra polysaccharide drink.

[0051] 1. Select mature, fresh, crisp and tender okra fruits to wash, remove the stems and trim, use a mixture of 0.1-0.5g / L zinc chloride and copper sulfate, and blanch at 85-95°C for 2-3 minutes. cool down.

[0052] 2. Make pulp according to the ratio of fruit to water 1:4, the soluble solid content in the pulp is 6%, and filter.

[0053] 3. Use whole okra juice as raw material, supplemented with stabilizer pectin, sodium alginate; sweetener white suga...

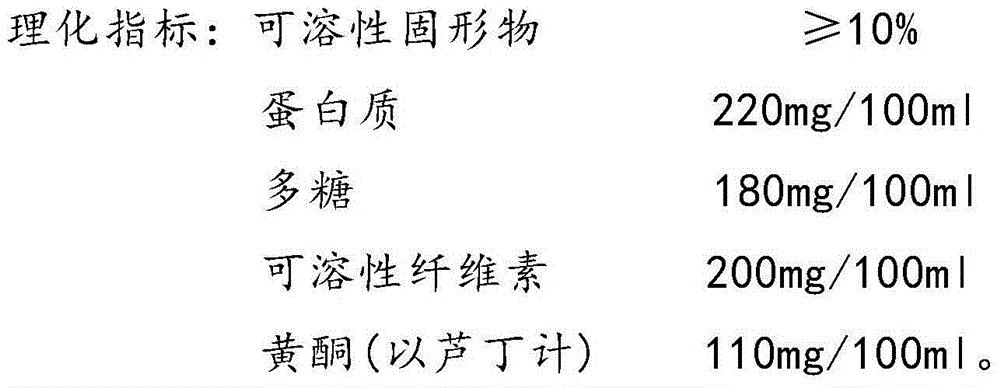

Embodiment 3

[0060] (1) A kind of okra polysaccharide beverage and preparation method thereof:

[0061] Okra juice 100%, white sugar 60-100g / L, sucralose 0.1-0.3g / L, xylitol 2-5g / L, citric acid 0.5-1g / L, tartaric acid 0.1-0.5g / L, Sodium citrate 0.1-0.3g / L, honey 0.1-0.3g / L, salt 1-2g / L, sodium isovitamin C 1-2g / L, pectin 1-3g / L, sodium alginate 0.5-1g / L L. Sodium copper chlorophyllin 6-12mg / L.

[0062] process, method

[0063] Process flow: Ripe okra fruit→cleaning→stalk removal→precooking→beating→filtering→compounding→homogenizing→sterilizing→okra polysaccharide drink.

[0064] 1. Select mature, fresh, crisp and tender okra fruits to wash, remove the stems and trim, use a mixture of 0.1-0.5g / L zinc chloride and copper sulfate, and blanch at 85-95°C for 2-3 minutes. cool down.

[0065] 2. Make pulp according to the ratio of fruit to water 1:6, the soluble solid content in the pulp is 5%, filter.

[0066] 3. Use whole okra juice as raw material, supplemented with stabilizer pectin, sod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com