Technology for keeping freshness of red bayberry juice

A process and processing technology, which is applied in the field of ultra-high pressure processing technology of bayberry juice, can solve the problems of short shelf life, damage to the flavor and nutritional quality of the juice, and easy spoilage, and achieve the effect of inhibiting degradation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

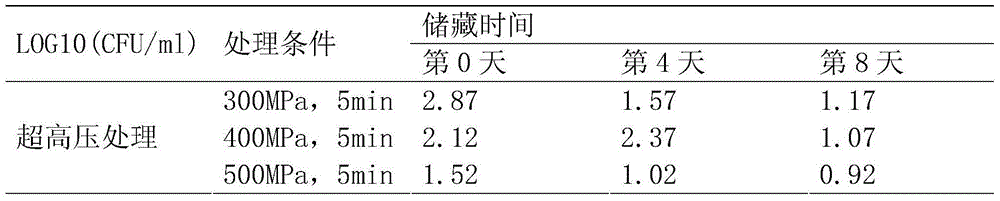

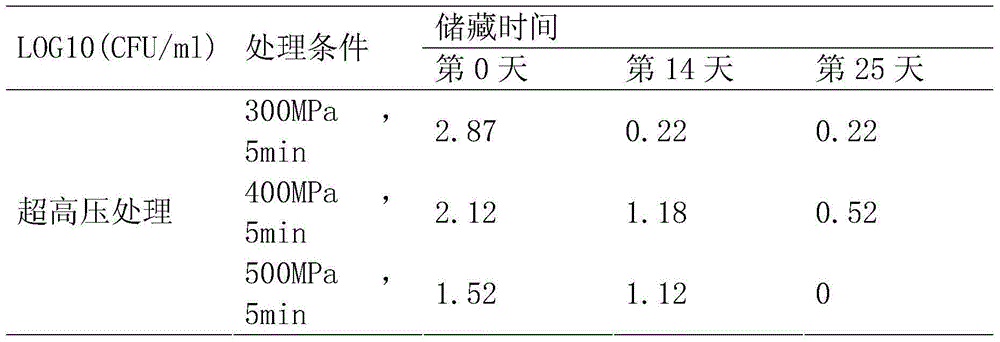

[0026] The bayberry juice was subjected to ultra-high pressure treatment (300MPa, 400MPa, 500MPa, 5min), and the blood pressure was measured immediately after treatment (day 0), storage at 25°C on the 4th and 8th day, and storage at 4°C on the 14th and 25th day. The total number of bacterial colonies. The specific results are shown in Table 1 and Table 2.

[0027] Table 1 The logarithmic value of the total number of colonies in bayberry juice after treatment under storage conditions of 25°C

[0028]

[0029] It can be seen from Table 1 that as the pressure increases, the total number of bacteria tends to decrease, and after 500MPa, 5min ultra-high pressure treatment, bayberry juice can meet the GB19297-2003 fruit and vegetable juice beverage hygienic standard - the total number of colonies is ≤ 100 / ml, And the total number of colonies showed an overall downward trend.

[0030] Table 2 The logarithmic value of the total number of colonies in bayberry juice after treatment ...

Embodiment 2

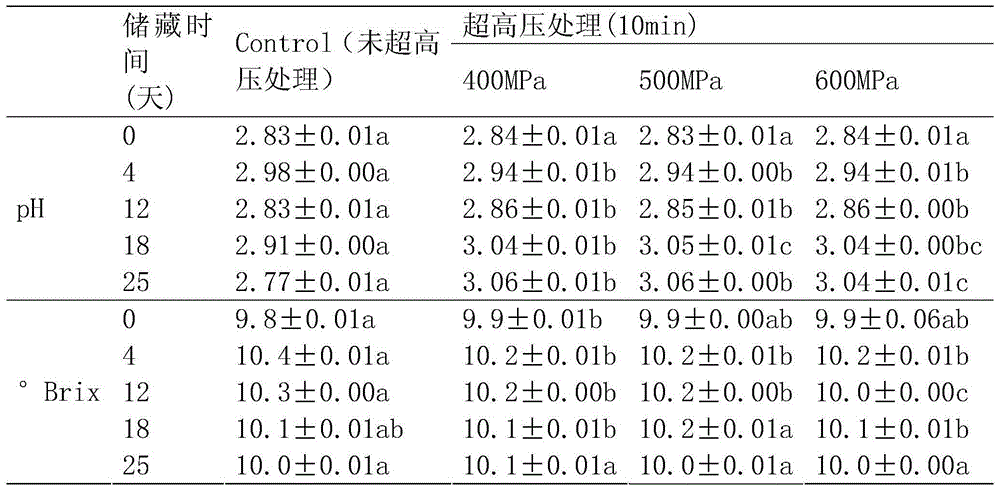

[0034] Objective: To detect the effect of pressure on the quality of bayberry juice in ultra-high pressure treatment

[0035] Red bayberry juice was treated under ultra-high pressure conditions of 400, 500, and 600 MPa respectively, and the holding time was 10 min. The results of ultra-high pressure treatment at different pressure levels on pH and soluble solids (°Brix) during the storage period (4°C and 25°C) of red bayberry juice were obtained. The specific results are shown in Table 3 and Table 4. And the impact on color, anthocyanin, ascorbic acid, the specific results are shown in Table 5.

[0036] The color (L, a, b values) of bayberry juice was measured at room temperature by the reflection mode of a colorimeter (CR-300, Minolta, Japan). The total color difference (ΔE) is calculated by the following formula:

[0037] ΔE=[(L-L0)2+(a-a0)2+(b-b0)2]1 / 2 (1)

[0038] Among them, L represents the brightness value; a represents the redness value; b represents the yellowness ...

Embodiment 3

[0052] Objective: To detect the effect of different holding time on the quality of bayberry juice in ultra-high pressure treatment.

[0053] Red bayberry juice was treated with 500MPa ultra-high pressure for 5, 10 and 15 minutes respectively, and the results of the effects of ultra-high pressure treatment at different times on pH and soluble solids (°Brix) during the storage period (4°C and 25°C) of bayberry juice were obtained. The results are shown in Table 6 and Table 7. And the impact on color, anthocyanin and ascorbic acid, the specific results are shown in Table 8.

[0054] Table 6 Effects of ultra-high pressure treatment with different holding times on pH and soluble solids (°Brix) of red bayberry juice during storage (4°C)

[0055]

[0056] Table 7 Effects of ultra-high pressure treatment with different holding times on pH and soluble solids (°Brix) of red bayberry juice during storage (25°C)

[0057]

[0058] It can be seen from Table 6 and Table 7 that three ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com