Method for preparing tobacco extract by utilizing waste and inferior tobacco leaves

A technology for waste and secondary tobacco leaves and tobacco extract, which is applied in the preparation of tobacco, tobacco, application, etc., can solve the problem of tobacco extract aroma fidelity, insufficient evaluation of cigarette effects, affecting the recycling efficiency of cigarette production scraps, and reducing the fragrance and softness of spices. It can improve the smoke permeability, improve the efficiency of recycling and improve the quality of cigarettes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

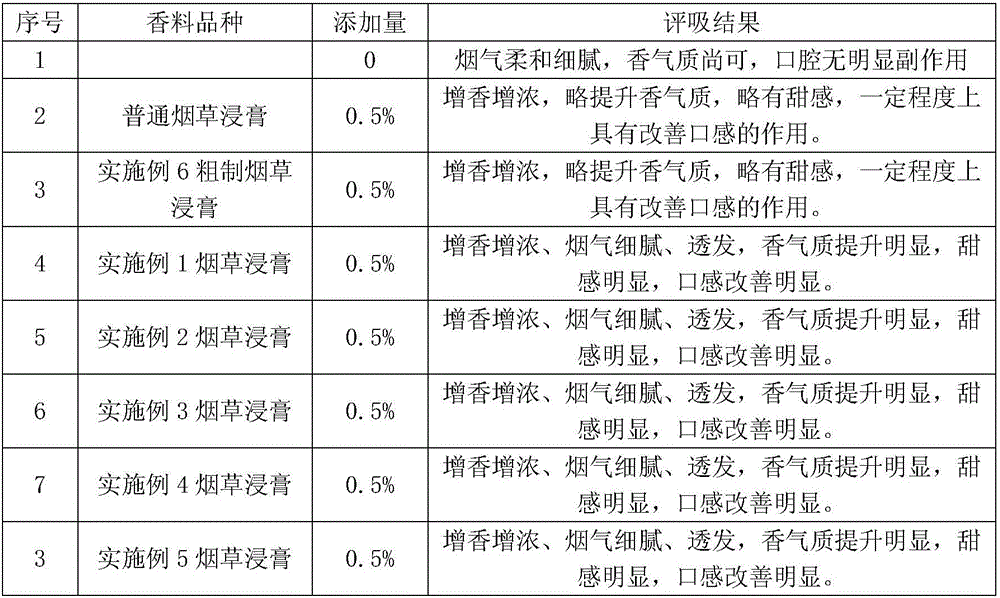

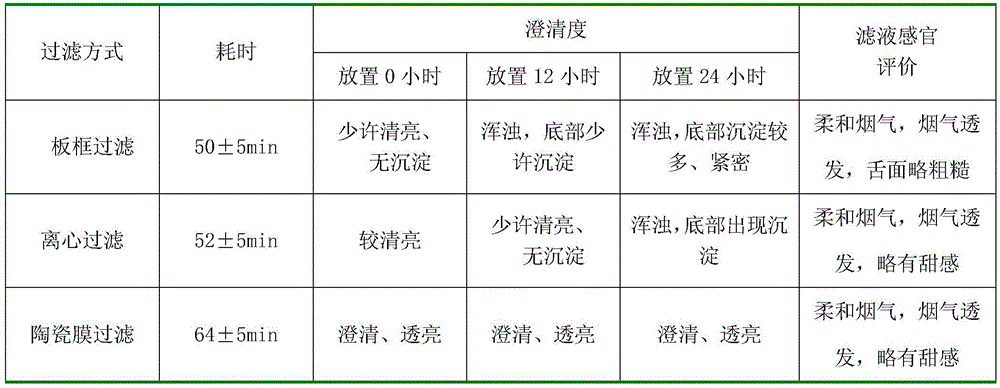

Examples

example 1

[0022] Example 1, a method for preparing tobacco extract by using waste tobacco leaves, the specific steps are as follows:

[0023] (1) Mixing tobacco dust in the packing workshop: tobacco leaf fragments: tobacco stems = 2:3:1 (mass ratio) to prepare raw materials for extracting waste and inferior tobacco leaves;

[0024] (2) Adding 7 times the weight of 50% ethanol solution to the prepared waste tobacco leaf extraction raw material, extracting for 4 hours at an extraction pressure of -0.04MPa and a temperature of 60°C to obtain a crude extract of waste tobacco leaves;

[0025] (3) concentrating the crude extract of waste tobacco leaves under reduced pressure until it has no ethanol smell, then add 7 times its weight of pure water and 4% of its weight of glucose in turn, and stir evenly to obtain an aqueous solution of crude waste extract of waste tobacco leaves;

[0026] (4) add its weight 0.1% cellulase (activity unit: 10000U / g) and 0.06% subtilisin (activity unit: 1.8 × 10 ...

example 2

[0031] Example 2, a method for preparing tobacco extract by using waste tobacco leaves, the specific steps are as follows:

[0032] (1) Mixing tobacco dust in the packing workshop: tobacco leaf fragments: tobacco stems = 2:2:1 (mass ratio) to prepare raw materials for extracting waste and inferior tobacco leaves;

[0033] (2) Add 15 times the weight of 30% ethanol solution to the waste tobacco leaf extraction raw material prepared in step (1), and extract for 5 hours at an extraction pressure of -0.06MPa and a temperature of 45°C to obtain crude waste tobacco leaves extract;

[0034] (3) Concentrate under reduced pressure the crude extract of waste tobacco leaves in step (2) to substantially no ethanol smell, then add 4 times of its weight in pure water and 2.5% of its weight in glucose, and stir evenly to obtain waste tobacco leaves Crude extract aqueous solution;

[0035] (4) add its weight 0.04% cellulase (activity unit: 10000U / g) and 0.08% subtilisin (activity unit: 1.8 ...

example 3

[0040] Example 3, a method for preparing tobacco extract by using waste tobacco leaves, the specific steps are as follows:

[0041] (1) Mixing tobacco dust in the packing workshop: tobacco leaf fragments: tobacco stems = 6:4:3 (mass ratio) to prepare raw materials for extracting waste and inferior tobacco leaves;

[0042] (2) Add 10 times the weight of 45% ethanol solution to the waste tobacco leaf extraction raw material prepared in step (1), and extract for 2 hours at an extraction pressure of -0.04MPa and a temperature of 40°C to obtain crude waste tobacco leaves extract;

[0043] (3) Concentrate under reduced pressure the crude extract of waste tobacco leaves obtained in step (2) to substantially no ethanol smell, then add 5 times of its weight in pure water and 5.5% of its weight in glucose, and stir evenly to obtain the waste tobacco leaves Tobacco leaf crude extract aqueous solution;

[0044] (4) Add successively its weight 0.15% cellulase (activity unit: 10000U / g) an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com