Nitrogen-doped porous carbon material and preparation method and application thereof

A porous carbon material, nitrogen-doped technology, applied in separation methods, chemical instruments and methods, and other chemical processes, etc., can solve problems such as unsuitability for industrialized large-scale production, environmental hazards, and complicated operations, and achieve convenient large-scale production. The effect of application, strong operability and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

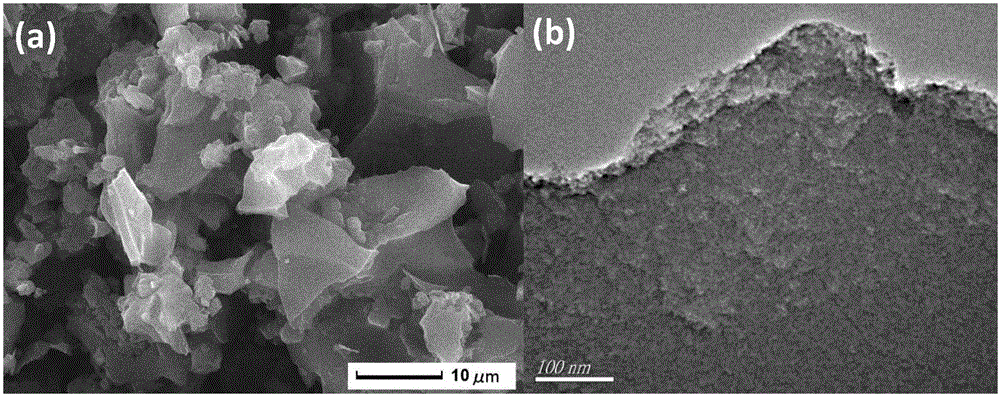

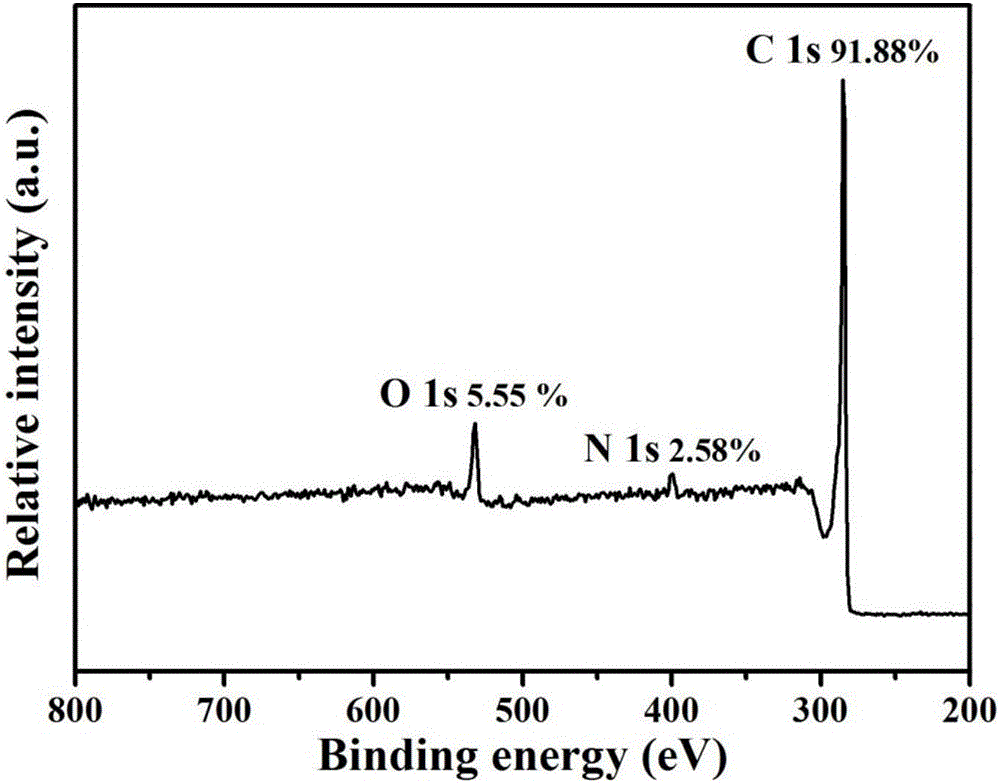

Embodiment 1

[0026] Weigh 5g of dipotassium ethylenediaminetetraacetic acid and put it in a nickel crucible, place it in a high temperature quartz tube furnace under N 2 Under the protection of air flow (20mL / min), the temperature was raised to 750°C at a rate of 3°C / min, maintained for 1 hour, and then cooled naturally. After pyrolysis, a black composite carbon material was obtained, and then an excess of 5% HCl (v / v) was added solution, immerse the composite carbon material, stir for 1 h, then wash until neutral, and vacuum dry at 80° C. for 12 h to obtain a nitrogen-doped porous carbon material.

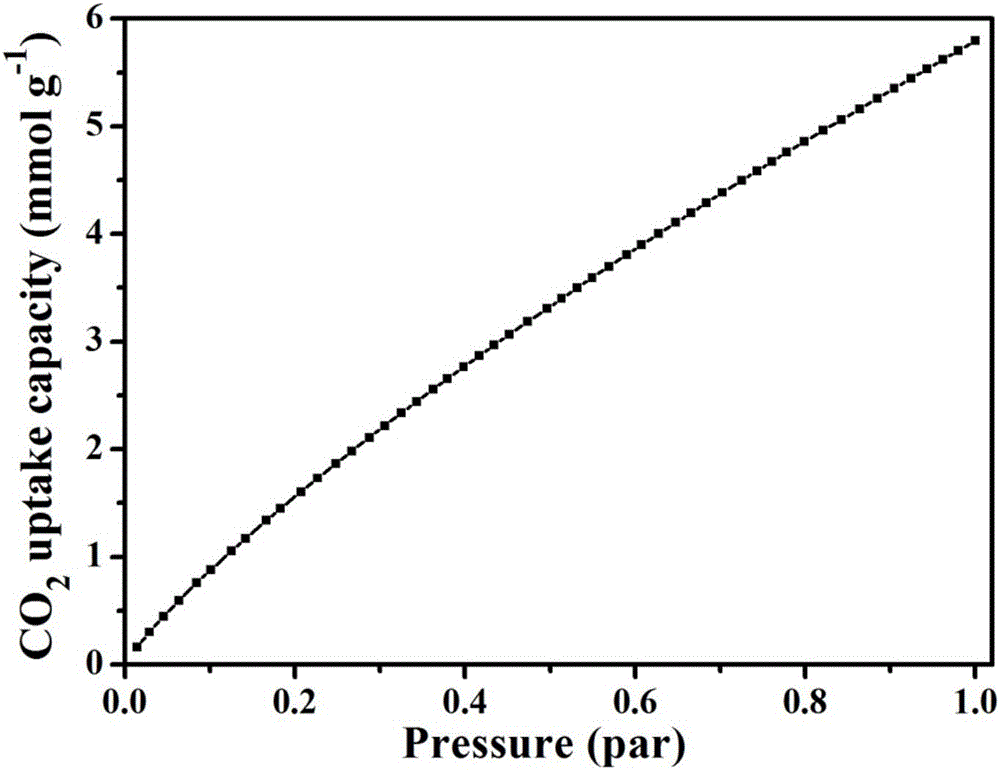

[0027] Applying porous carbon materials to CO 2 The method of adsorption is:

[0028] After soaking and cleaning the porous carbon material obtained in (1) with a mixture of distilled water and absolute ethanol (prepared at a volume ratio of 1:1), put it in a blast drying oven at 100°C for 10 hours, and then put it in a vacuum drying oven Dry for 2h. After cooling, weigh a certain mass and ...

Embodiment 2

[0031] Weigh 5g of ethylenediaminetetraacetic acid tripotassium salt into a nickel crucible, place it in a high-temperature quartz tube furnace under the protection of Ar flow (60mL / min), raise the temperature to 650°C at a heating rate of 5°C / min, and maintain it for 3h After natural cooling, a black composite carbon material is obtained after pyrolysis, and then an excess of 10% HNO is added 3 (v / v) solution, immerse the composite carbon material, stir for 0.5 h, then wash, and vacuum dry at 60° C. for 24 h to obtain a nitrogen-doped porous carbon adsorption material.

[0032] Using this material to adsorb CO 2 , the results showed that the adsorption capacity of the material was 5.38mmol / g (273K).

Embodiment 3

[0034] Weigh 5g of ethylenediaminetetraacetic acid disodium salt and put it in a nickel crucible, place it in a high temperature quartz tube furnace under N 2 Under the protection of air flow (100mL / min), the temperature was raised to 900°C at a heating rate of 8°C / min, maintained for 0.5h and then cooled naturally. After pyrolysis, a black composite carbon material was obtained, and then an excess of 3% HNO was added 3 (v / v) solution, immerse the composite carbon material, stir for 2 hours, then wash until neutral, and dry in vacuum at 110° C. for 6 hours to obtain a nitrogen-doped porous carbon adsorption material.

[0035] Using this material to adsorb CO 2 , the results showed that the adsorption capacity of the material was 5.06mmol / g (273K).

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

| Average pore diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap