Laser cavitation cleaning enhancement device for crankshaft oil hole and cleaning enhancement method

A technology of crankshaft oil hole and strengthening device is applied in cleaning methods and utensils, chemical instruments and methods, laser welding equipment, etc., to achieve the effects of easy control, high efficiency, and improved mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In this embodiment, laser is used to induce the generation of cavitation bubbles that originally caused side effects such as erosion damage to water conservancy machinery and equipment, and work efficiency is reduced. Cleansing and intensive life-extending treatments.

[0022] The present invention will be described in further detail below in conjunction with specific examples.

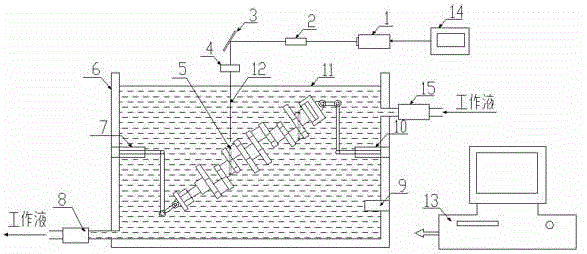

[0023] Such as figure 1 As shown, a laser cavitation cleaning and strengthening device for crankshaft oil holes includes a laser generating unit, a water tank 6 and a computer 13, the laser generating unit is located at the upper end of the working fluid carrier 6, and the laser generating unit includes a YAG laser 1. The beam expander 2, the total reflection mirror 3 and the beam conversion and adjustment device 4 are used to form a high-energy cavitation bubble that cleans and strengthens the inner wall of the oil hole. The working fluid carrier 6 is equipped with a working medium, preferab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com