A device and method for surface modification of laser-induced cavitation bubbles

A surface modification, laser-induced technology, applied in the field of surface modification devices, to achieve the effects of easy control, elimination of processing defects, and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

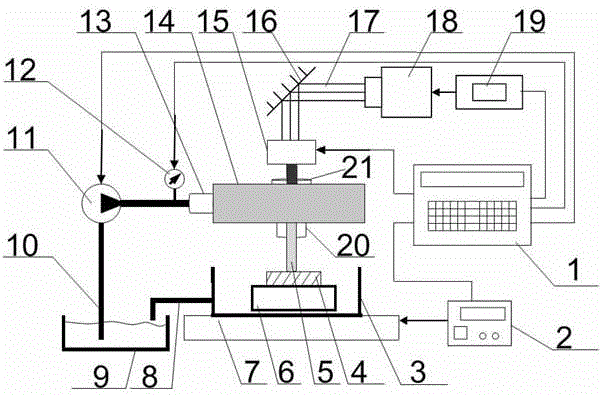

Method used

Image

Examples

Embodiment 1

[0025] The base material is selected as an iron sheet with a thickness of 1mm, and the surface of the iron sheet is decontaminated with alcohol or acetone, and the treated iron sheet is placed on the five-axis linkage workbench together with the pad and the water tank A; adjust the YAG laser process Parameters, the laser energy is 21mJ, the output wavelength is 1.06μm, the pulse width is 30ns, and the spot diameter is 1mm; at the same time, adjust the output power of the water pump to keep the water pressure at the water inlet at 0.05MPa, and the water in the pressure water chamber passes through the laser After the action, cavitation bubbles are generated, and the cavitation bubbles containing high-energy gas act on the surface of the iron sheet along with the water column. Adjust the five-axis linkage worktable to completely treat the surface of the iron sheet, and then dry and clean the iron sheet. It has been determined that the residual compressive stress is between 260 MP...

PUM

| Property | Measurement | Unit |

|---|---|---|

| energy | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com