Premixed mechanized spraying mortar and production method thereof

A technology of spraying mortar and ready-mixing, which is applied in the direction of sustainable waste treatment, solid waste management, and climate sustainability. It can solve the problems of mechanized construction, easy generation of stone powder, and poor fluidity, and achieve long-distance transportation. The effect of less springback and pulp loss, and simplified preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

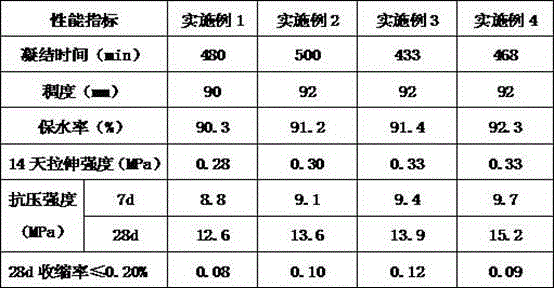

Embodiment 1

[0021] 60 parts of aggregate (the weight ratio of medium sand and fine sand is 55:12), 10 parts of 42.5 Portland cement, 8 parts of fly ash, 1 part of redispersible latex powder, 0.5 part of cellulose ether, wood fiber After weighing 0.1 part, 0.02 part of air-entraining agent and 0.05 part of super lubricant, put fly ash, redispersible latex powder, cellulose ether, wood fiber, air-entraining agent and super lubricant into the mixer for stirring Mix, then add 42.5 Portland cement into the mixer and mix, and finally add the aggregate into the mixer and mix, then put it into the finished product packaging tank, inspect the package, and obtain the product.

Embodiment 2

[0023] 70 parts of aggregate (the weight ratio of medium sand and fine sand is 65: 23), 12 parts of 42.5 Portland cement, 12 parts of fly ash, 2 parts of redispersible latex powder, 1 part of cellulose ether, wood fiber After weighing 0.2 parts, 0.03 parts of air-entraining agent and 1 part of super lubricant, put fly ash, redispersible latex powder, cellulose ether, wood fiber, air-entraining agent and super lubricant into the mixer for stirring Mix, then add 42.5 Portland cement into the mixer and mix, and finally add the aggregate into the mixer and mix, then put it into the finished product packaging tank, inspect the package, and obtain the product.

Embodiment 3

[0025] 75 parts of aggregate (the weight ratio of medium sand and fine sand is 60:15), 14 parts of 42.5 Portland cement, 15 parts of fly ash, 2.5 parts of redispersible latex powder, 1.5 parts of cellulose ether, wood fiber After weighing 0.4 parts, 0.04 parts of air-entraining agent and 1.5 parts of super lubricant, put fly ash, redispersible latex powder, cellulose ether, wood fiber, air-entraining agent and super lubricant into the mixer for stirring Mix, then add 42.5 Portland cement into the mixer and mix, and finally add the aggregate into the mixer and mix, then put it into the finished product packaging tank, inspect the package, and obtain the product.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com