Spray seeding matrix and preparation method thereof

A technology of substrates and mass fractions, applied in the direction of planting substrates, botany equipment and methods, culture media, etc., can solve the problem of weakened water and soil conservation effect of soil spraying, short binder action time, and reduced slope stability To achieve the effect of improving slope stability, improving soil and water conservation effect, and improving anti-scouring ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

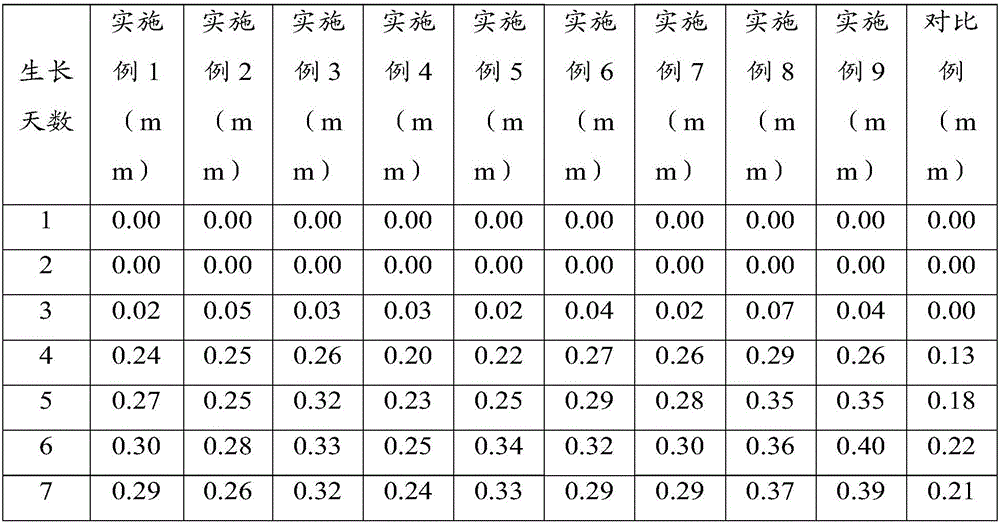

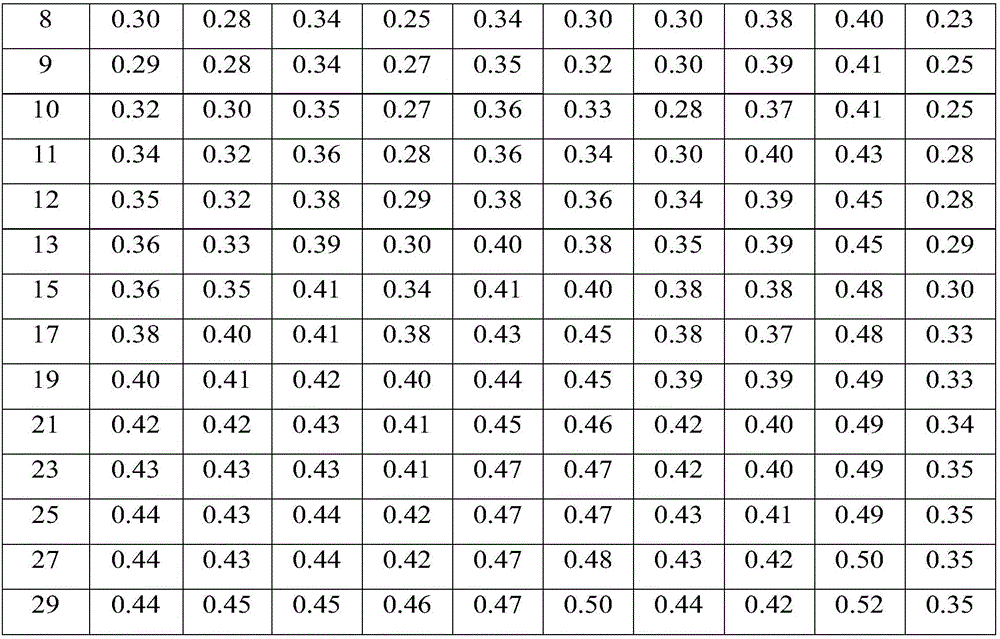

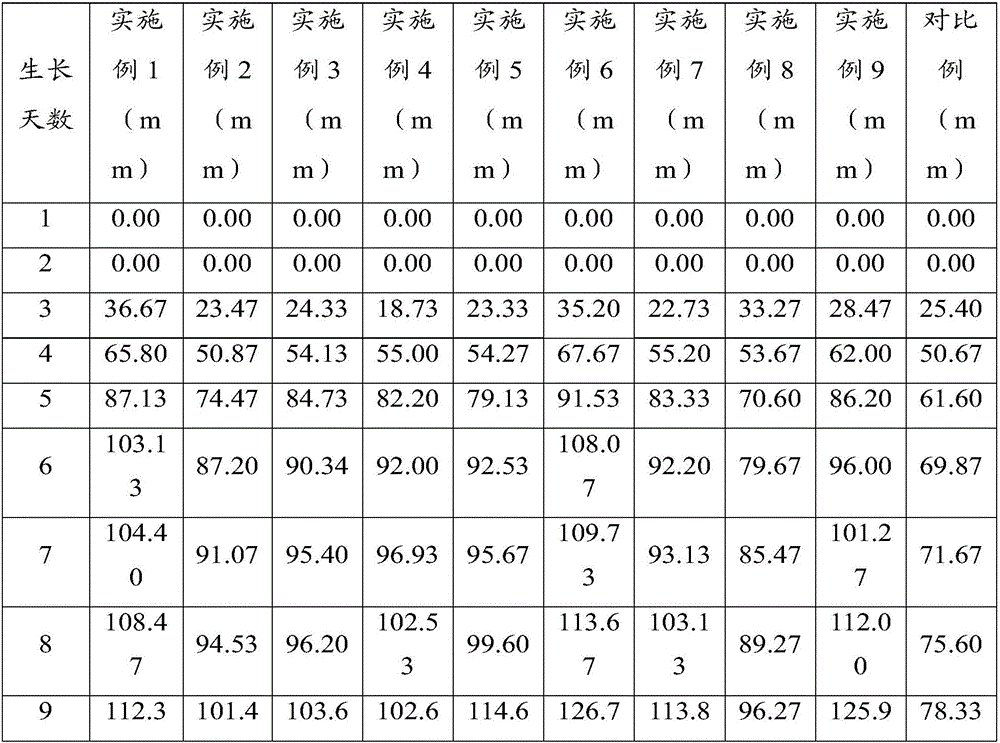

Embodiment 1

[0063] A method for preparing a spraying substrate. In terms of parts by mass, 5000 parts of soil, 2500 parts of corn stalks, 20 parts of water retaining agent, 10 parts of adhesive, 12000 parts of chicken manure, accounting for 1% of the total volume of the spraying substrate % of brick and tile waste (the volume ratio of 2mm-5mm large particle size aggregate and small particle size aggregate with a particle size not greater than 0.038mm is 1:5) is added to the slope spraying machine, stirred and mixed to obtain a Spray the substrate.

Embodiment 2

[0065] A method for preparing a spraying substrate. In terms of parts by mass, 25,000 parts of soil, 12,500 parts of corn stalks, 50 parts of water-retaining agent, 15 parts of adhesive, and 20,000 parts of peat soil, accounting for 20 parts of the total volume of the spraying substrate % of brick and tile waste (the volume ratio of 2mm-5mm large particle size aggregate and small particle size aggregate not greater than 0.038mm is 5:1) is added to the slope spraying machine, stirred and mixed to obtain a Spray the substrate.

Embodiment 3

[0067] A preparation method of a spraying substrate, in parts by mass, 10000 parts of soil, 5000 parts of corn stalks, 30 parts of water retaining agent, 11 parts of binder, 14000 parts of quick-acting compound fertilizer (N fertilizer, P The mass ratio of fertilizer, K fertilizer is N fertilizer: P fertilizer: K fertilizer=2: 1: 2), account for the brick and tile waste of 5% of the total volume of the sprayed matrix (wherein the large particle size aggregate of 2mm-5mm and The volume ratio of small particle size aggregates with a particle size not greater than 0.038mm is 1:2) into the slope spraying machine, stirring and mixing to obtain a spraying matrix.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com