Leisure sneaker sole and manufacturing method thereof

A technology for sports shoes and soles, applied in the directions of soles, footwear, applications, etc., can solve the problems of heavy weight, unsatisfactory wear resistance, lack of portability, etc., and achieve the effect of improving wearing comfort and good cushioning performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

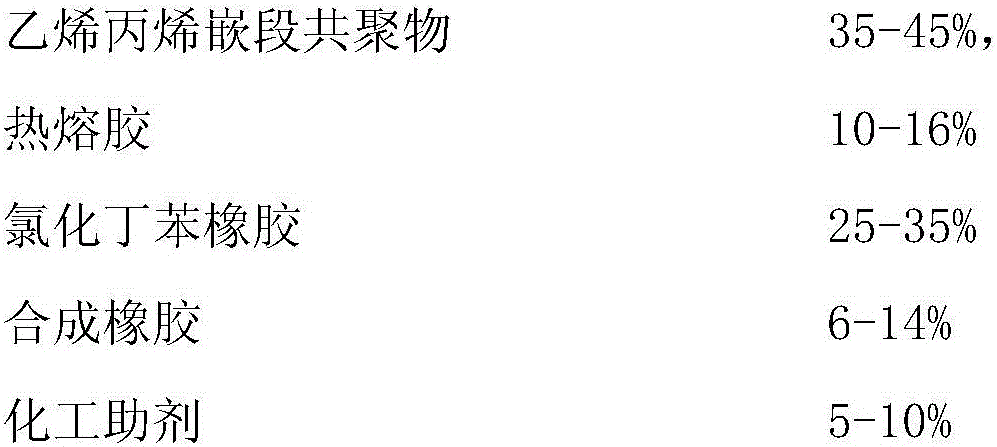

[0032] The sole of a leisure sports shoe of the present invention is mainly composed of the following components and weight percentages:

[0033]

[0034] The chemical auxiliaries described therein include cross-linking agents, foaming agents and flow aids, zinc oxide, stearic acid, zinc stearate, rubber and plastic accelerators, dispersants, stabilizers, fast-cooking agents, and anti-aging agents Any 5 kinds of mixed composition. Said cross-linking agent and foaming agent respectively account for 10% and 20% of the total amount of chemical auxiliaries, and the rest are the mixing amounts of the other 5 kinds, which should be simply divided equally.

[0035] A method for making the soles of leisure sports shoes as mentioned above, which mainly includes banburying, refining, granulation, cooling and stirring, and finally molding into outsole shoe materials in a plastic molding machine, specifically:

[0036] 1) During banburying, first put 2 / 3 of the raw materials into the ...

Embodiment 2

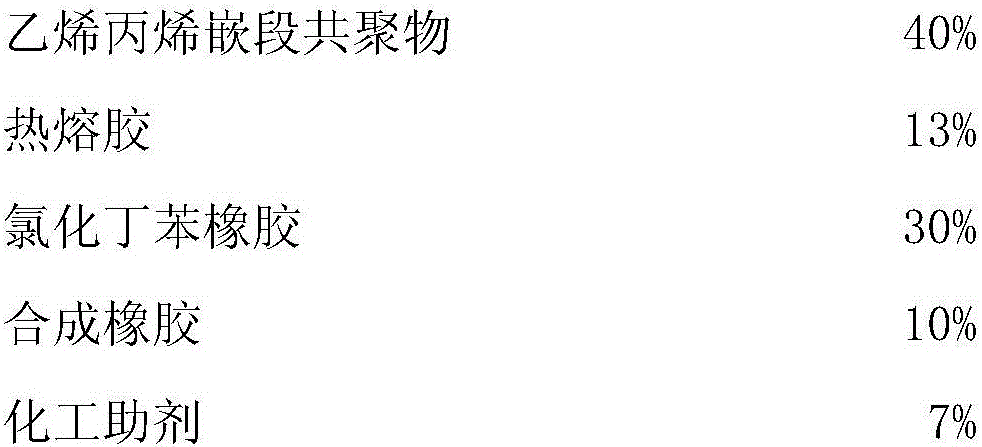

[0043] Embodiment 2, a kind of leisure sports shoe sole of the present invention, it is mainly made up of following components and weight percent ratio:

[0044]

[0045] The chemical auxiliaries described therein include cross-linking agents, foaming agents and flow aids, zinc oxide, stearic acid, zinc stearate, rubber and plastic accelerators, dispersants, stabilizers, fast-cooking agents, and anti-aging agents A mixture of at least 6 of them.

[0046] Said cross-linking agent and foaming agent respectively account for 25% and 35% of the total amount of chemical auxiliaries, and the rest are the mixing amounts of the other 6 kinds, and it is also appropriate to divide them equally.

[0047] A method for making the soles of leisure sports shoes as mentioned above, which mainly includes banburying, refining, granulation, cooling and stirring, and finally molding into outsole shoe materials in a plastic molding machine, specifically:

[0048] 1) During banburying, first put...

Embodiment 3

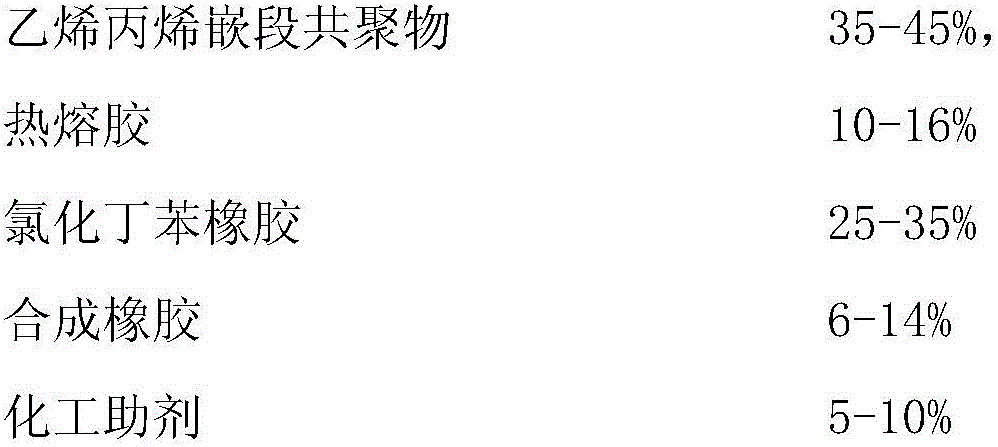

[0055] Embodiment 3: a kind of leisure sports shoe sole of the present invention, it is mainly made up of following components and weight percentage:

[0056]

[0057] The chemical auxiliaries described therein include cross-linking agents, foaming agents and flow aids, zinc oxide, stearic acid, zinc stearate, rubber and plastic accelerators, dispersants, stabilizers, fast-cooking agents, and anti-aging agents A mixture of at least 4 of them.

[0058] Said cross-linking agent and foaming agent respectively account for 16% and 28% of the total amount of chemical auxiliaries, and the rest are the mixing amounts of the other 4 kinds, and it is appropriate to divide the balance equally.

[0059] A method for making the soles of leisure sports shoes as mentioned above, which mainly includes banburying, refining, granulation, cooling and stirring, and finally molding into outsole shoe materials in a plastic molding machine, specifically:

[0060] 1) During banburying, first put ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com