Thermoplastic foaming polyurethane fiber board, production method and uses thereof

A foamed polyurethane and thermoplastic technology, which is applied in the fields of thermoplastic foamed polyurethane fiberboard, its production and use, and can solve problems such as easy coloring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0102] Thermoplastic foamed polyurethane fiberboards were prepared as follows:

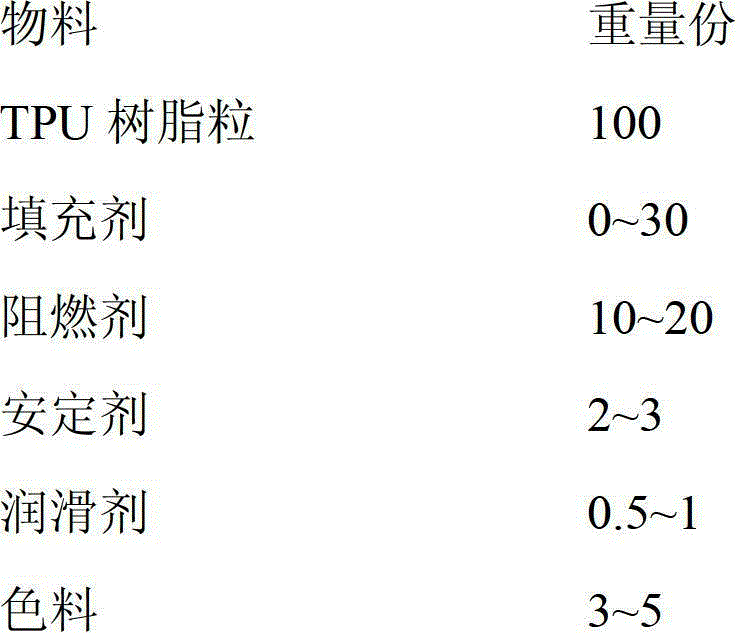

[0103] Preparation of A surface layer:

[0104]

[0105] Stir the above raw materials with a mixer for 5-10 minutes, then use a 10,000-horsepower machine (internal mixer) to heat at 140°C for 5-8 minutes, squeeze and mature, and then heat and knead at 150°C with a double-roller mill. The four-roller calender presses the tablet, the thickness is adjusted to about 0.30mm, embossed, cooled, and the coiling is about 250m per bundle. Finally, use a printing machine to print graphics and text to obtain the A surface layer.

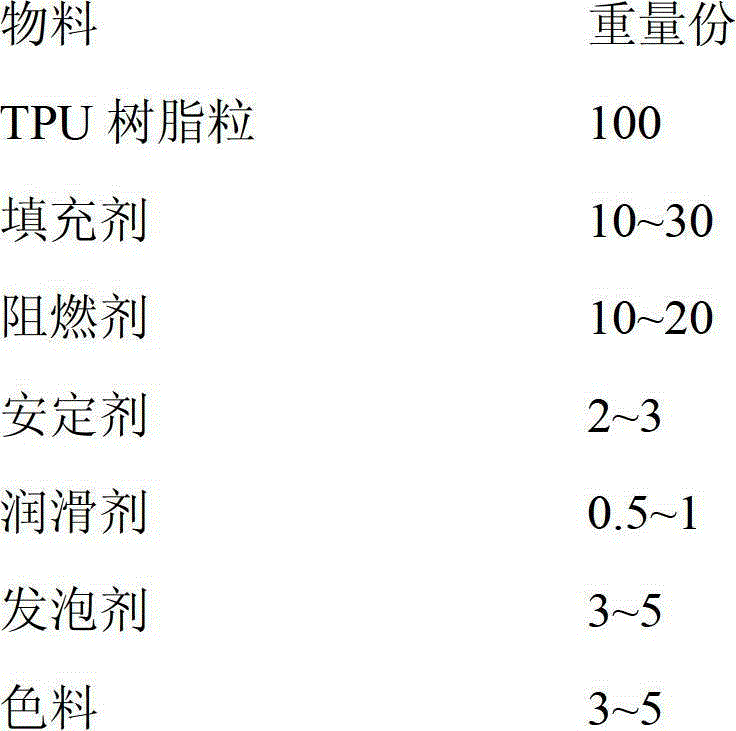

[0106] Preparation of B middle sheet:

[0107]

[0108] Stir and mix the above raw materials with a mixer for 5-10 minutes, then use a 10,000-horsepower machine (internal mixer) to heat to 140°C-150°C and squeeze the material for 5-7 minutes. Roller kneading, four-roller calender compression, thickness control about 1.0mm, cooling, coiling about 250m per bundle, to obtain B...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com