Children's non-slip functional shoes

A functional and anti-slip technology, which is applied in the field of daily necessities, can solve the problems of lack of research on the influence of performance, the decline of static and dynamic properties of rubber-based composite materials, and weak interface bonding.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

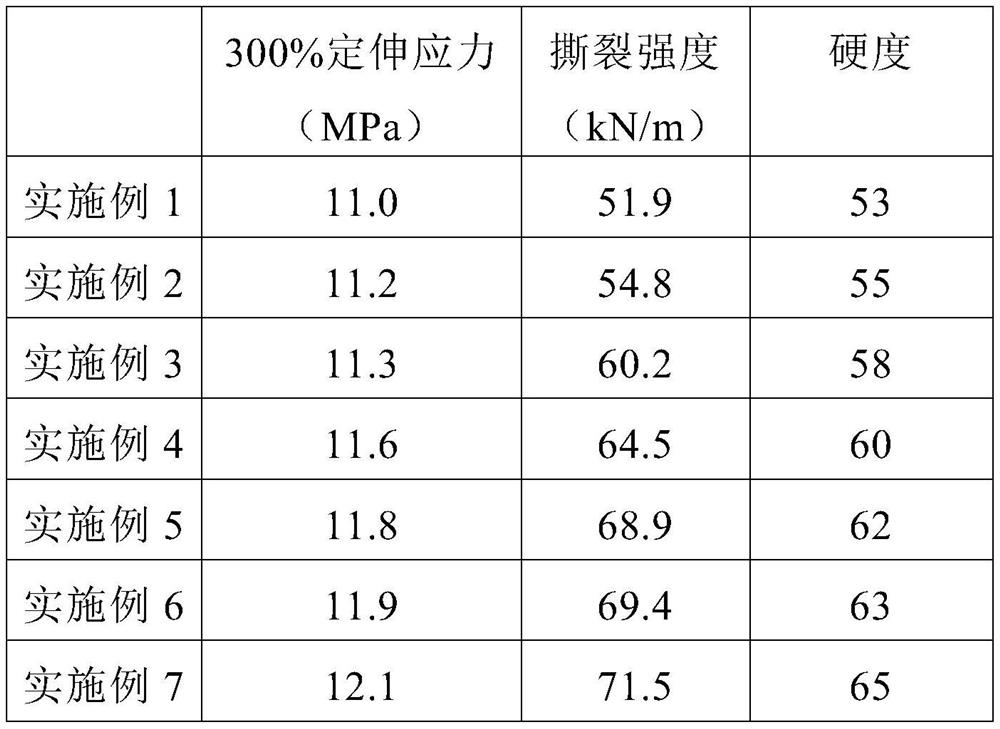

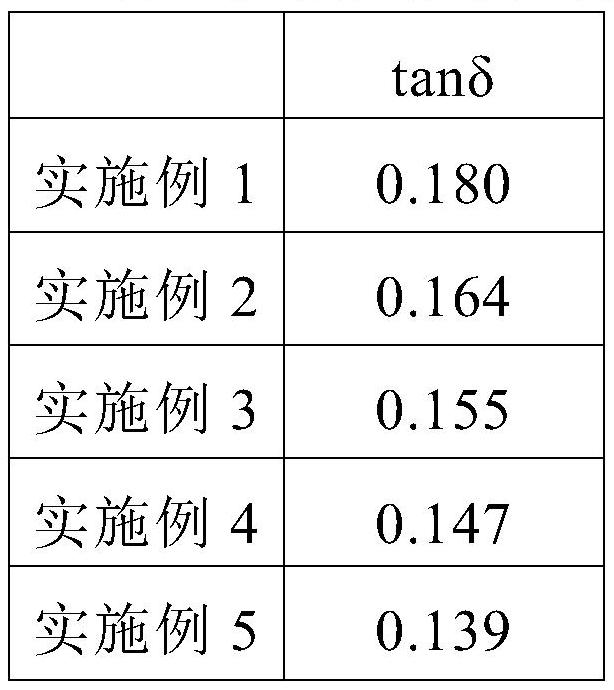

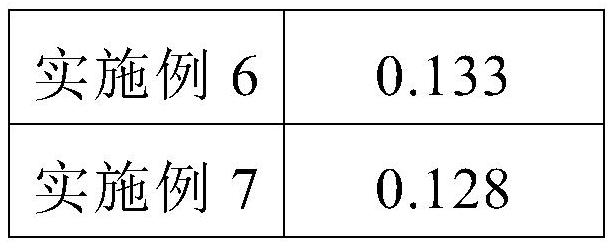

Examples

Embodiment 1

[0061] The anti-slip functional shoes for children comprise an anti-slip rubber sole and a shoe body, and the anti-slip rubber sole is made of an anti-slip rubber material.

[0062] The formula of the anti-slip rubber material is: 40 parts by weight of butyl rubber, 40 parts by weight of butadiene rubber, 8 parts by weight of terpene resin, 1 part by weight of rosin, 6 parts by weight of zinc oxide, 5 parts by weight of stearic acid, paraffin wax 0.5 parts by weight, 50 parts by weight of carbon black, 5 parts by weight of anti-aging agent, 10 parts by weight of plasticizer, 3 parts by weight of accelerator, and 5 parts by weight of sulfur powder.

[0063] The anti-slip rubber sole is processed through the following processes:

[0064] (1) Weighing: accurately weigh the above-mentioned anti-slip rubber material according to the formula;

[0065] (2) The first section of internal mixing procedure: put in butyl rubber, butadiene rubber and terpene resin, keep at 90°C for 2 minu...

Embodiment 2

[0070] The anti-slip functional shoes for children comprise an anti-slip rubber sole and a shoe body, and the anti-slip rubber sole is made of an anti-slip rubber material.

[0071] The formula of the anti-slip rubber material is: 40 parts by weight of butyl rubber, 40 parts by weight of butadiene rubber, 8 parts by weight of terpene resin, 1 part by weight of rosin, 6 parts by weight of zinc oxide, 5 parts by weight of stearic acid, paraffin wax 0.5 parts by weight, 50 parts by weight of modified carbon black, 5 parts by weight of antioxidant, 10 parts by weight of plasticizer, 3 parts by weight of accelerator, and 5 parts by weight of sulfur powder.

[0072] The anti-slip rubber sole is processed through the following processes:

[0073] (1) Weighing: accurately weigh the above-mentioned anti-slip rubber material according to the formula;

[0074] (2) The first stage of internal mixing procedure: put in butyl rubber, butadiene rubber and terpene resin, keep at 90°C for 2 mi...

Embodiment 3

[0080] The anti-slip functional shoes for children comprise an anti-slip rubber sole and a shoe body, and the anti-slip rubber sole is made of an anti-slip rubber material.

[0081] The formula of the anti-slip rubber material is: 40 parts by weight of butyl rubber, 40 parts by weight of butadiene rubber, 8 parts by weight of terpene resin, 1 part by weight of rosin, 6 parts by weight of zinc oxide, 5 parts by weight of stearic acid, paraffin wax 0.5 parts by weight, 50 parts by weight of modified carbon black, 5 parts by weight of antioxidant, 10 parts by weight of plasticizer, 3 parts by weight of accelerator, and 5 parts by weight of sulfur powder.

[0082] The anti-slip rubber sole is processed through the following processes:

[0083] (1) Weighing: accurately weigh the above-mentioned anti-slip rubber material according to the formula;

[0084] (2) The first stage of internal mixing procedure: put in butyl rubber, butadiene rubber and terpene resin, keep at 90°C for 2 mi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com