A construction method for solidified pile embankment with dredging fill

A construction method and soil filling technology, which can be used in infrastructure engineering, roads, roads, etc., can solve the problems of hindering the pace of engineering construction, inaccessible construction machinery, low permeability and strength, etc. The effect of the scarcity of stone resources and the reduction of processing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

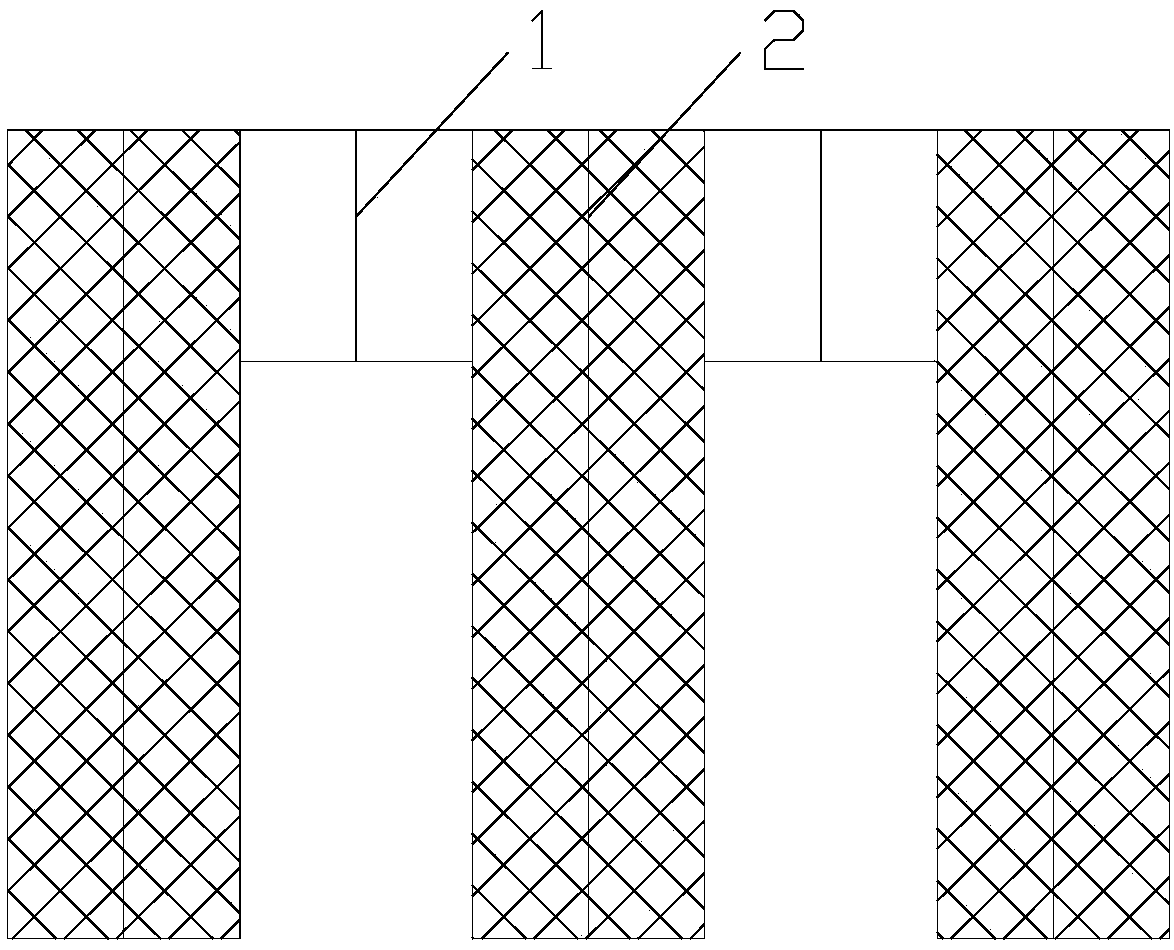

[0028] see figure 1 and figure 2 As shown, they are respectively the pile position section view of the dredger fill soil solidified pile subgrade of the present invention and the pile position plan view of the dredger fill soil solidified pile subgrade in this embodiment.

[0029] combine figure 1 and figure 2 Shown, a kind of dredging fill solidified pile embankment is made up of short pile 1 and long pile 2, and the pile heads of described short pile 1 and described long pile 2 are on the same horizontal plane, and described short pile 1 and described long pile 2. An upper overall solidified pile structure and a lower deep solidified pile structure arranged at intervals are formed. The integral solidified pile meets the requirement of bearing capacity, and the deep layer solidified pile meets the requirement of settlement.

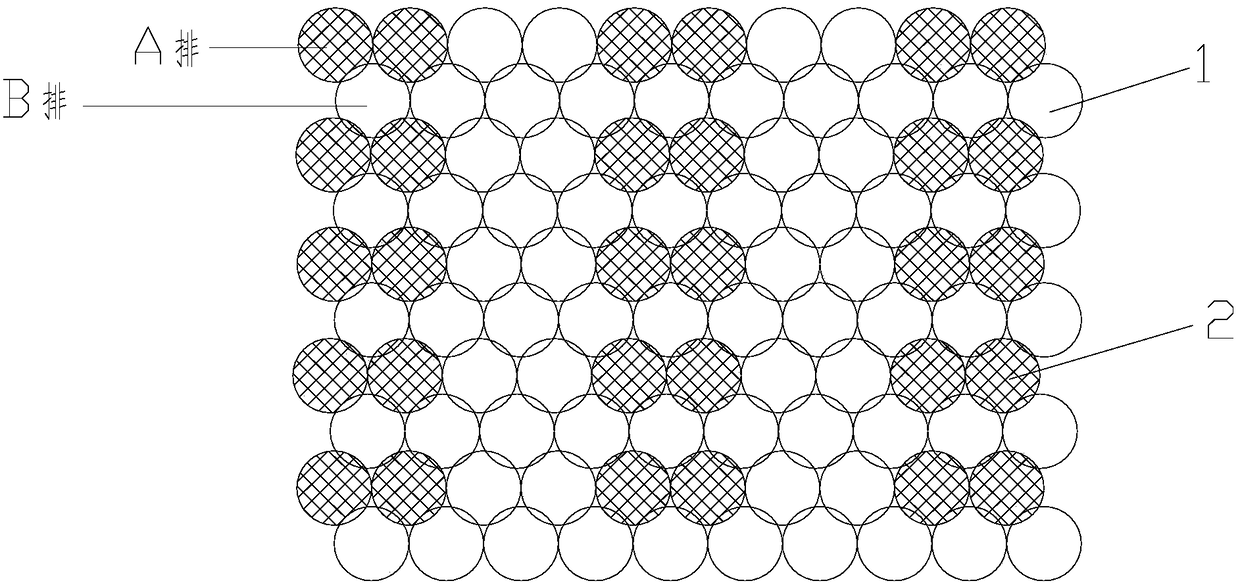

[0030] Such as figure 2 As shown, the pile position layout of a kind of dredging soil curing pile embankment is the layout of row A and the layou...

Embodiment 2

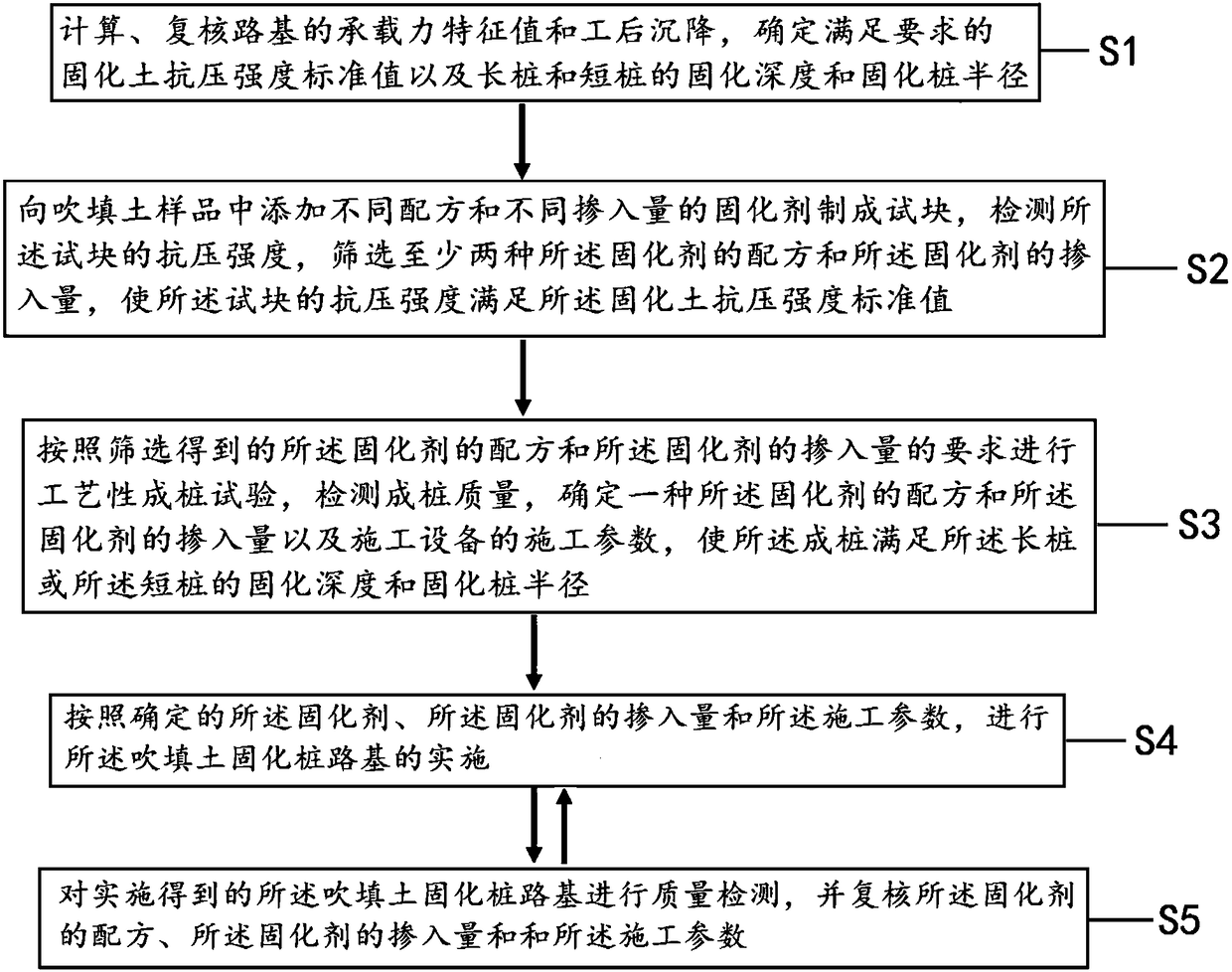

[0034] As above-mentioned a kind of dredging fill solidified pile embankment, the difference of this embodiment is that, as image 3 Shown, it is the flow chart of the construction method of dredger fill solidified pile embankment of the present invention, and the construction method of described dredge fill solidified pile embankment comprises the following steps:

[0035] S1: According to the geological survey report and relevant engineering experience, design the standard value of the compressive strength of the solidified soil, the solidification depth and the radius of the solidified pile of the long pile and the short pile, and then calculate and check the characteristic value of the bearing capacity of the subgrade and the post-construction settlement , to determine the design parameters that meet the requirements.

[0036] The characteristic value of the bearing capacity of the subgrade includes the characteristic value of the bearing capacity of the surface of the so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com