Salvage method for large-diameter pile buried hammer

A large diameter, pile hammer technology, applied in sheet pile wall, construction, infrastructure engineering and other directions, can solve the problems of construction period and investment loss, difficulty in handling accidents, loss of pile hammer cost, etc., to reduce safety hazards and reduce salvage costs. , the effect of saving construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

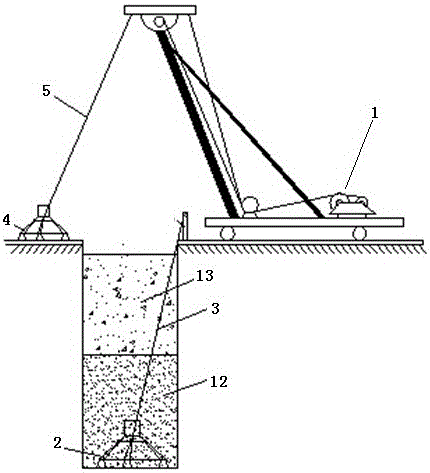

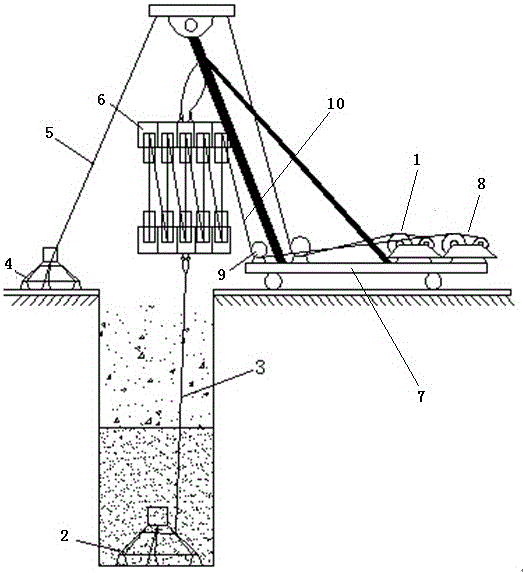

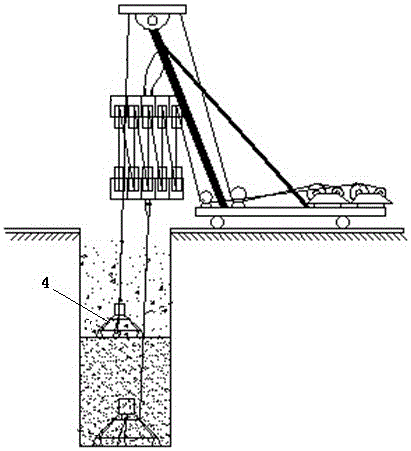

Image

Examples

Embodiment 1

[0039] Hole collapse pretreatment: observe which side of the casing the pile foundation collapsed hole occurs on, measure the depth and width of the hole collapsed on site, and check whether the casing is disturbed when the hole collapses. After the hole collapse occurs, a crane should be arranged to lift and move the pile driver immediately to prevent the hole from further expanding and causing greater losses. In view of the collapsed hole, backfill treatment shall be taken immediately. The backfill shall be processed in two layers. The lower layer shall be backfilled with clay mixed with cement ash to 1m above the bottom of the casing, and then the inside of the casing shall be backfilled with gravel. After backfilling, the broken casing shall be taken out. On the stone top surface, mud water and gravel backfill can play a role of drainage and back pressure consolidation. After backfilling, place it for 24 hours to check whether the inside and outside of the casing sink. If s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com