Coal-mining method of loose coal seam

A coal mining method and coal seam technology, which are applied in surface mining, mining equipment, earthwork drilling, etc., can solve problems such as restricting safe and efficient mining of mines, large-scale coal fragmentation accidents, and easy occurrence of safety problems, and achieve high application. The effect of promoting value, safe and efficient coal mining process, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

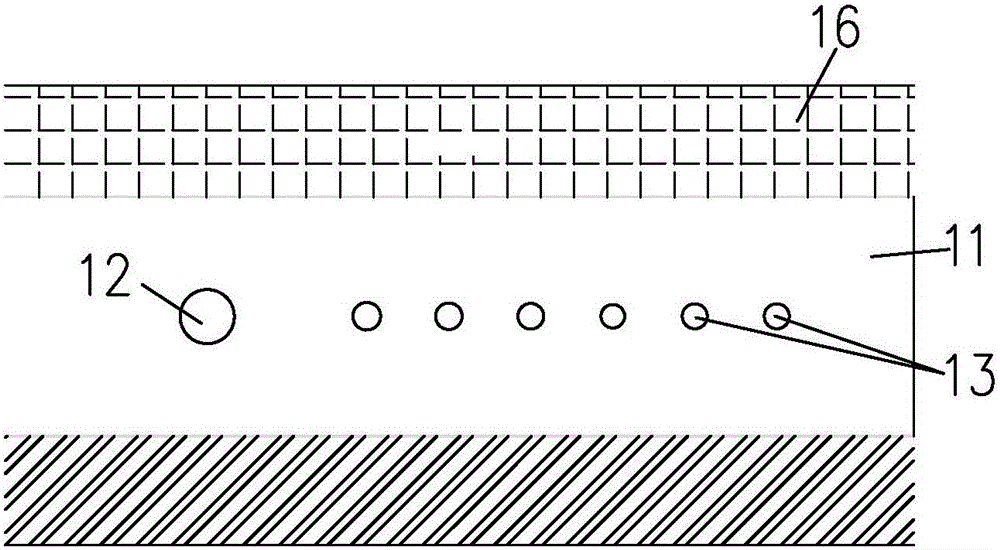

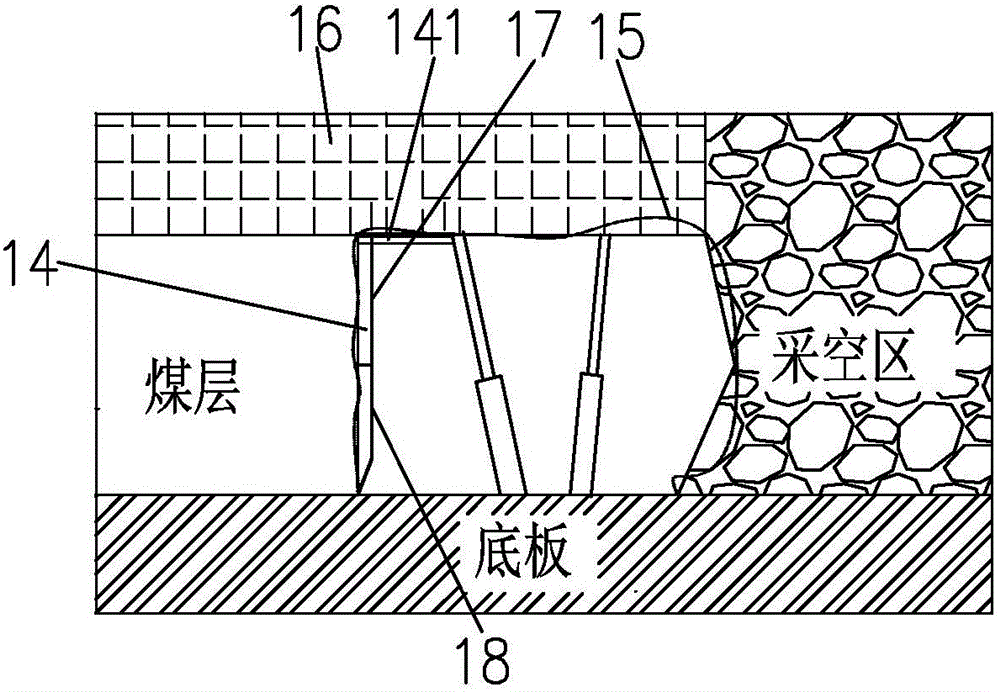

[0020] The coal mining method of a kind of loose coal seam of the present invention comprises the following steps:

[0021] (1) Water injection holes 12 are drilled in the middle part of the coal seam 11 of the track level roadway, and the static pressure water injection is continued for 24 hours in the water injection holes 12, and then several inspection holes 13 are made around the water injection holes 12, and each inspection hole 13 is successively away from the water injection holes 12, The distance between two adjacent inspection holes 13 is 1m, and the water content of each inspection hole 13 is detected. The distance between the point where the water content is greater than 7% and the center of the water injection hole 12 is the wetting radius of the water injection hole 12, and the water injection hole is determined. Wet radius r of 12;

[0022] (2) At 120m ahead of the mining face in the track entry and transportation entry, set a water injection point every two wet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com