Wireless temperature measuring device for brickkiln

A wireless temperature measurement, brick kiln technology, applied in the direction of measuring devices, electrical devices, thermometers, etc., can solve the problems of reduced labor intensity and labor, increased labor costs, and high labor intensity, reducing the number of times and work intensity, avoiding The production of black heart bricks and the effect of improving the firing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

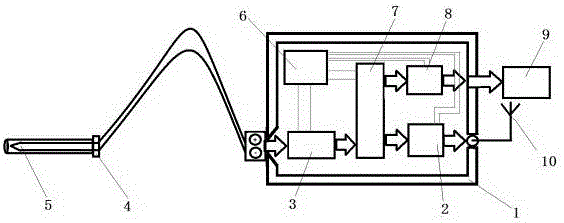

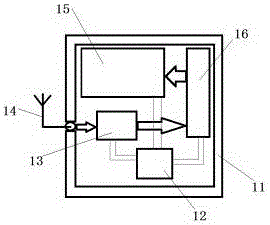

[0016] The invention relates to a brick kiln wireless temperature measuring device which can be used for real-time monitoring of the temperature in the kiln, which includes a measuring and transmitting end system and a hand-held receiving system, see figure 1 , the measurement and transmitter system includes: main board 1, radio frequency circuit 2, thermocouple processing circuit 3, thermocouple protection armor 4, thermocouple 5, power supply circuit 6, processor 7, display processing circuit 8, display 9, Antenna 10, see figure 2 , The handheld receiving system includes: a main board 11 , a power supply circuit 12 , a radio frequency circuit 13 , an antenna 14 , a display processing circuit and a display 15 , and a processor 16 .

[0017] figure 1 Among them, the main board 1 is a PCB board made of bakelite material, the radio frequency circuit 2 is composed of a radio frequency transceiver chip SI4432 and its processing circuit, the thermocouple processing circuit 3 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com