Anti-lightning power distribution cabinet based on CO gas detection function

A technology for gas detection and power distribution cabinets, applied in measuring devices, material analysis through electromagnetic means, instruments, etc., can solve problems such as failure to guarantee normal work and personnel safety, and lack of detection capabilities in lightning protection power distribution cabinets. Effects of improving sensitivity and selectivity, increasing contact area, and promoting reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

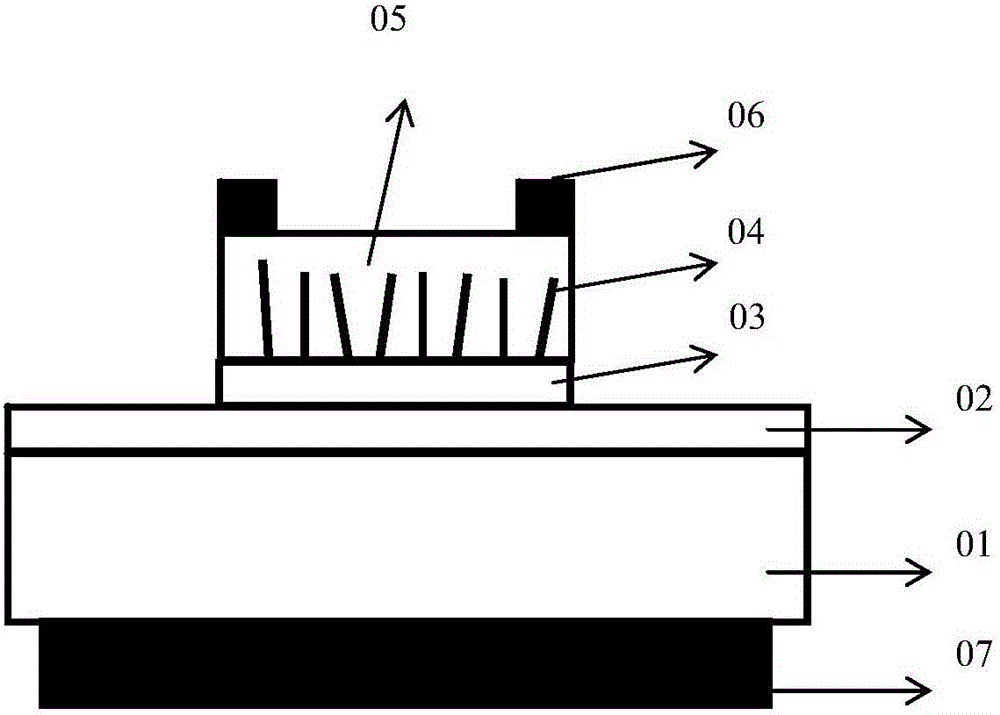

[0037] The embodiment of the present application relates to a lightning protection power distribution cabinet based on the CO gas detection function, and the lightning protection power distribution cabinet is equipped with a CO gas sensor; figure 1 As shown, the CO gas sensor includes a Si substrate (01), a silicon oxide film (02) formed on the Si substrate (01), a W film (03) placed on the silicon oxide film (02) , WO formed on the W film (03) 3 Nanowire film (04), coated on WO 3 SnO on nanowire films (04) 2 Nano film (05), in SnO 2 Two Pt electrodes (06) made on the nano film (05) and a heating module (07) located below the Si substrate; the WO 3 The length of the nanowire is 1000-7000nm.

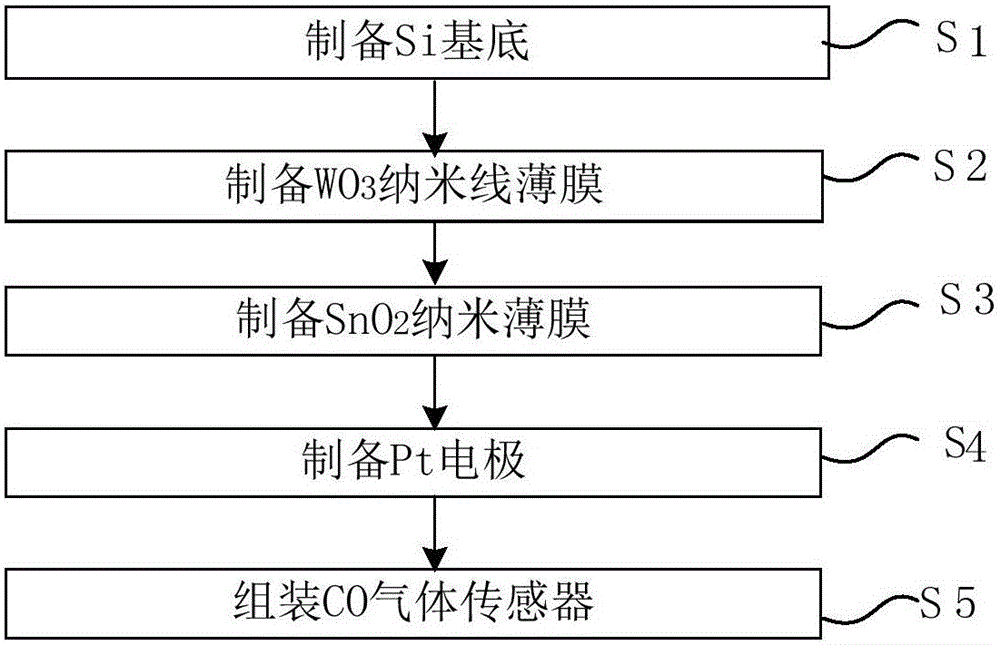

[0038] Preferably, as figure 2 , the preparation method of CO gas sensor comprises the steps:

[0039] Step 1, prepare the Si substrate:

[0040] Take a silicon wafer of a certain size (5cm×5cm), and ultrasonically clean it with acetone, ethanol, and deionized water in sequence, a...

Embodiment 2

[0054] The embodiment of the present application relates to a lightning protection power distribution cabinet based on the CO gas detection function, and the lightning protection power distribution cabinet is equipped with a CO gas sensor; figure 1 As shown, the CO gas sensor includes a Si substrate (01), a silicon oxide film (02) formed on the Si substrate (01), a W film (03) placed on the silicon oxide film (02) , WO formed on the W film (03) 3 Nanowire film (04), coated on WO 3 SnO on nanowire films (04) 2 Nano film (05), in SnO 2 Two Pt electrodes (06) made on the nano film (05) and a heating module (07) located below the Si substrate; the WO 3 The length of the nanowire is 1000-6000nm.

[0055] Preferably, as figure 2 , the preparation method of CO gas sensor comprises the steps:

[0056] Step 1, prepare the Si substrate:

[0057] Take a silicon wafer of a certain size (5cm×5cm), and ultrasonically clean it with acetone, ethanol, and deionized water in sequence, a...

Embodiment 3

[0071] The embodiment of the present application relates to a lightning protection power distribution cabinet based on the CO gas detection function, and the lightning protection power distribution cabinet is equipped with a CO gas sensor; figure 1 As shown, the CO gas sensor includes a Si substrate (01), a silicon oxide film (02) formed on the Si substrate (01), a W film (03) placed on the silicon oxide film (02) , WO formed on the W film (03) 3 Nanowire film (04), coated on WO 3 SnO on nanowire films (04) 2 Nano film (05), in SnO 2 Two Pt electrodes (06) made on the nano film (05) and a heating module (07) located below the Si substrate; the WO 3 The length of the nanowire is 1000-5000nm.

[0072] Preferably, as figure 2 , the preparation method of CO gas sensor comprises the steps:

[0073] Step 1, prepare the Si substrate:

[0074] Take a silicon wafer of a certain size (5cm×5cm), and ultrasonically clean it with acetone, ethanol, and deionized water in sequence, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com