Organic thin-film transistor gas sensor and preparation method thereof

A gas sensor and organic thin film technology, applied in the sensor field, can solve the problems of inconvenient practical application and unstable instrument performance, and achieve the effects of improving stability and measurement accuracy, improving selectivity, and suppressing errors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

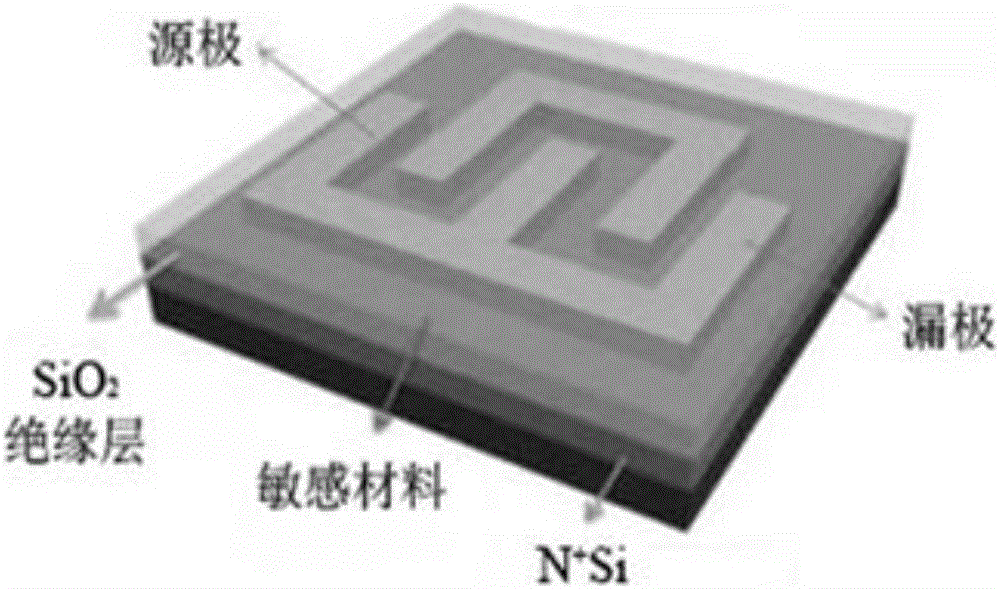

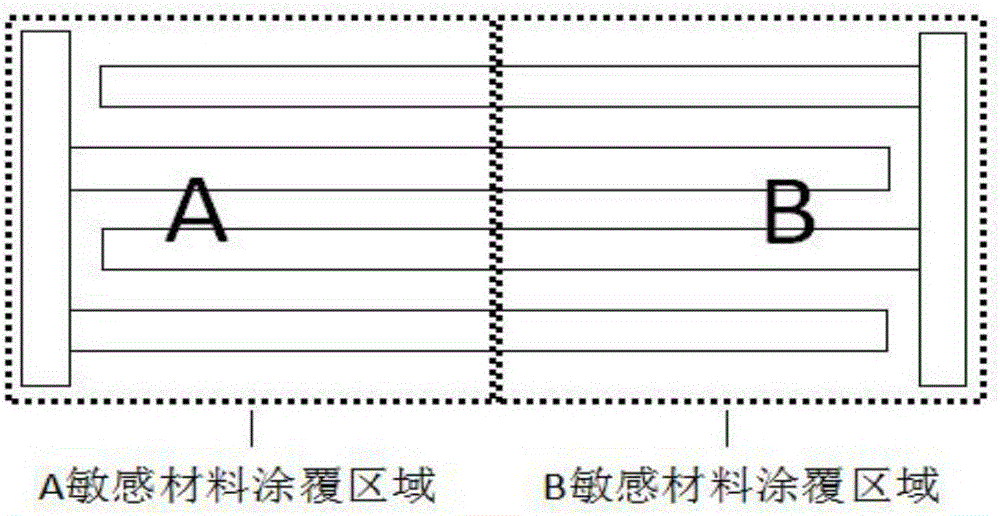

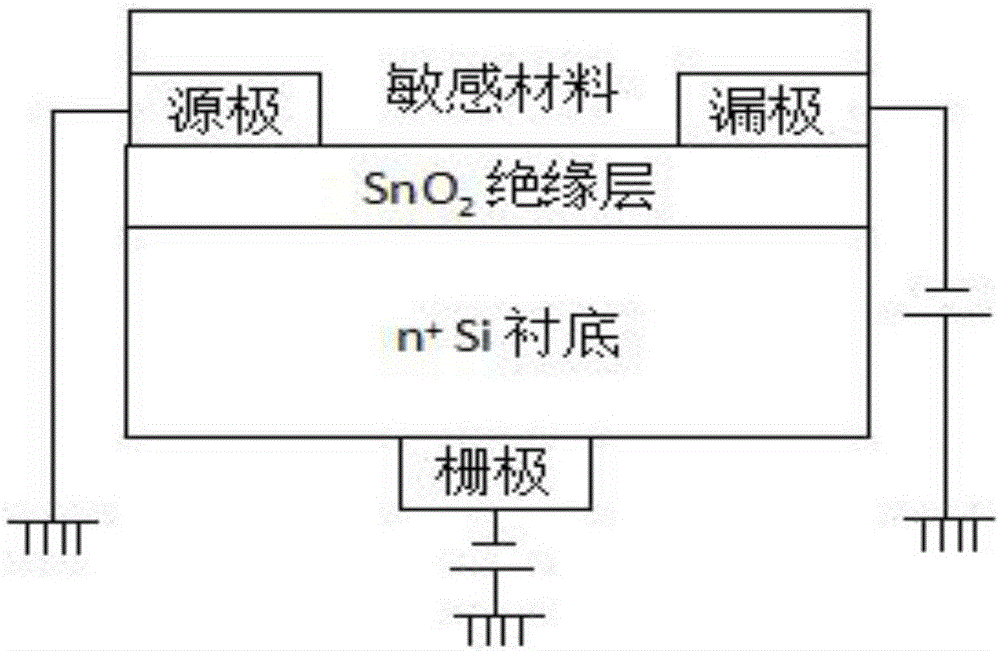

[0038] Such as figure 1 As shown, the present invention provides an organic thin film transistor gas sensor, which adopts a bottom-gate-bottom-contact structure, including: a gate located under an insulating substrate and a source, drain electrode and an active layer on the surface located on the insulating substrate; wherein , the channel between the source and the drain is designed as a gold interdigital electrode structure, the interdigital electrode spacing is 25 μm, and the channel width-to-length ratio is 160. The active layer takes the symmetrical axis of the gold interdigital electrode as the axis of symmetry is divided into two symmetrical partitions, such as figure 2 The gas-sensing material A is deposited in one partition, and the gas-sensing material B is deposited in the other partition. The gas-sensing material A and the gas-sensing material B are organic semiconductor gas-sensing thin films with different responses to the same specific gas.

[0039] Such as ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com