Cement kiln temperature control system

A temperature control system, a technology for cement kilns, applied in temperature control, control/regulation systems, temperature control by electric means, etc., can solve the problem of reducing cement production quality, kiln system temperature drop, wind pressure thermal fluctuations, etc. problems, to achieve the effect of improving reliability and stability, saving energy consumption, and reducing temperature control errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

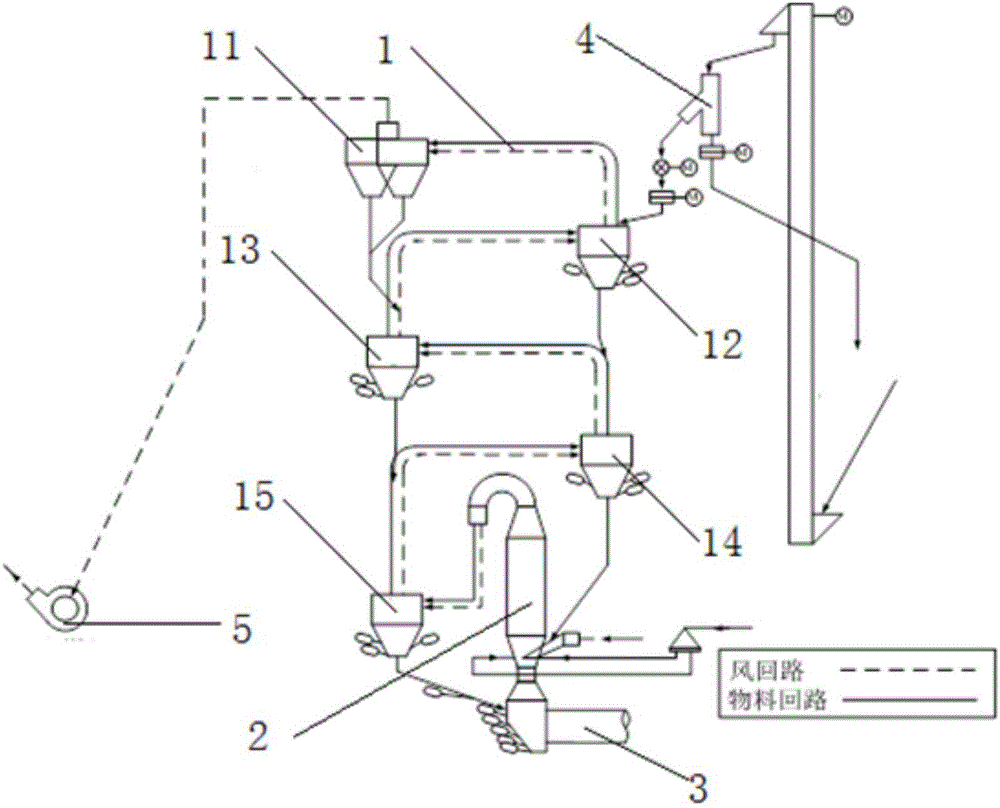

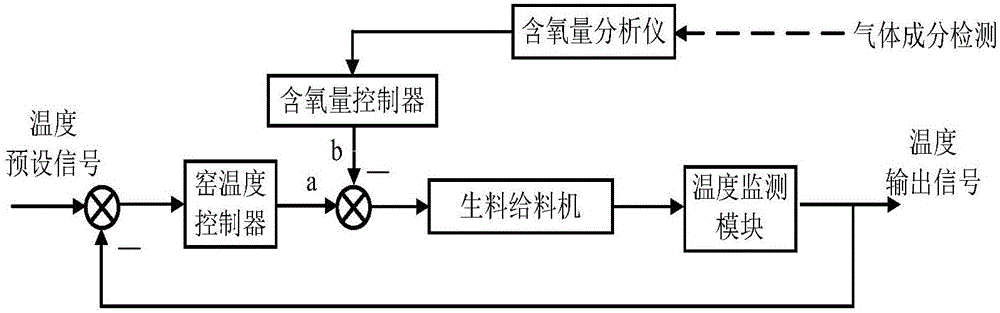

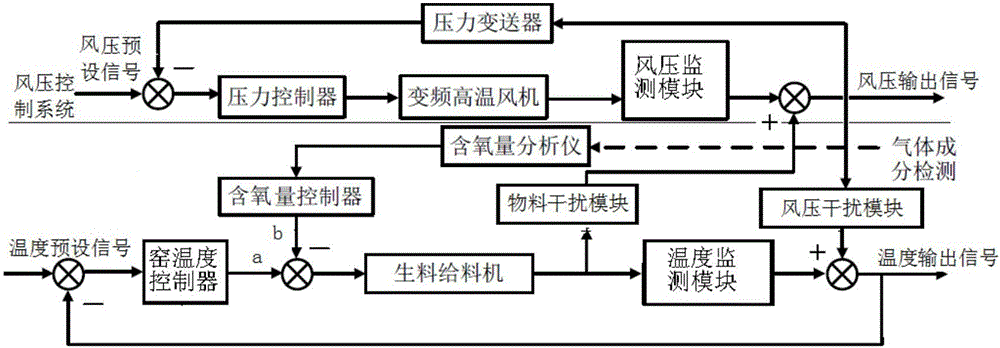

[0026] The cement production process is a complex physical and chemical reaction process, especially the calcination process of cement clinker has the characteristics of obvious time delay, large inertia, nonlinearity and interference uncertainty. It is particularly important to affect the temperature control of the firing zone during calcination. In this embodiment, the temperature control mainly controls the temperature of the firing zone of the rotary kiln. A preset temperature value of the firing zone is set in the kiln system. Adjust the temperature control system to stabilize the temperature of the firing zone at this temperature value; in order to make the temperature control more stable, predict the temperature of the kiln system, install an oxygen content detector in the kiln system, and set the oxygen content The comparison between the set value of the quantity value and the actual value predicts the temperature of the system. When the kiln system is congested or lack...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com