Preparation method and application of perovskite thin film

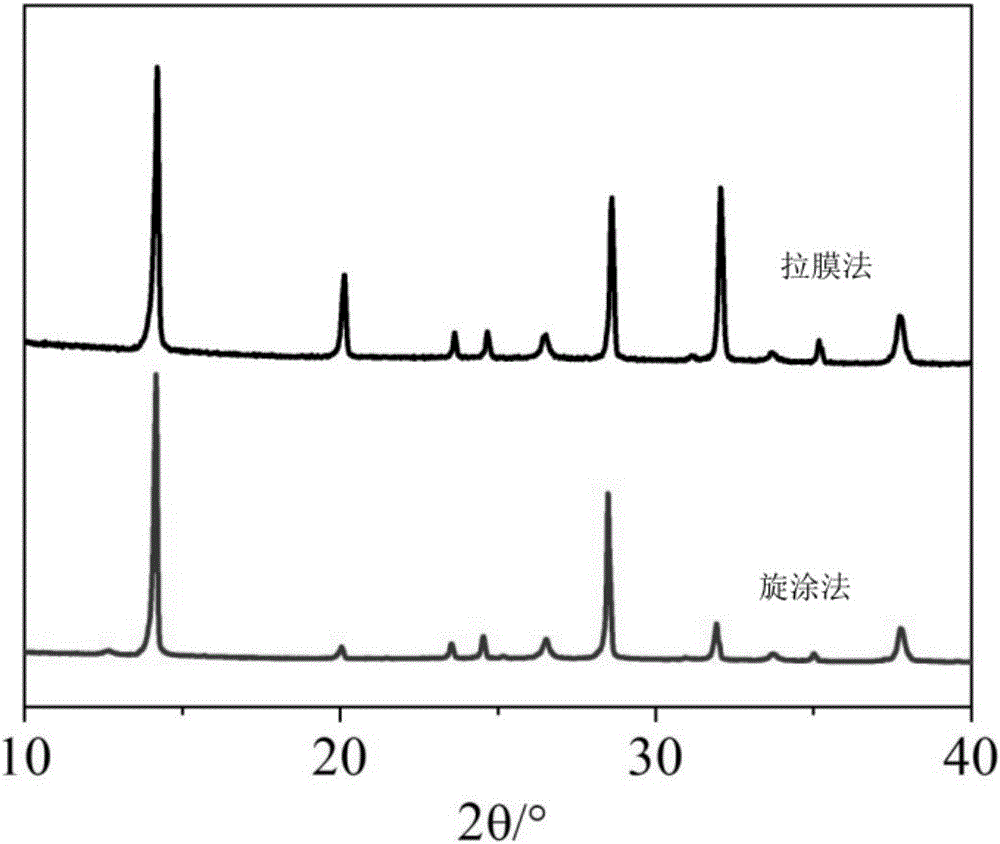

A perovskite and thin film technology, applied in the field of solar cells, can solve problems such as scarcity of technology, and achieve the effects of good film quality, low production cost, and controllable film thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

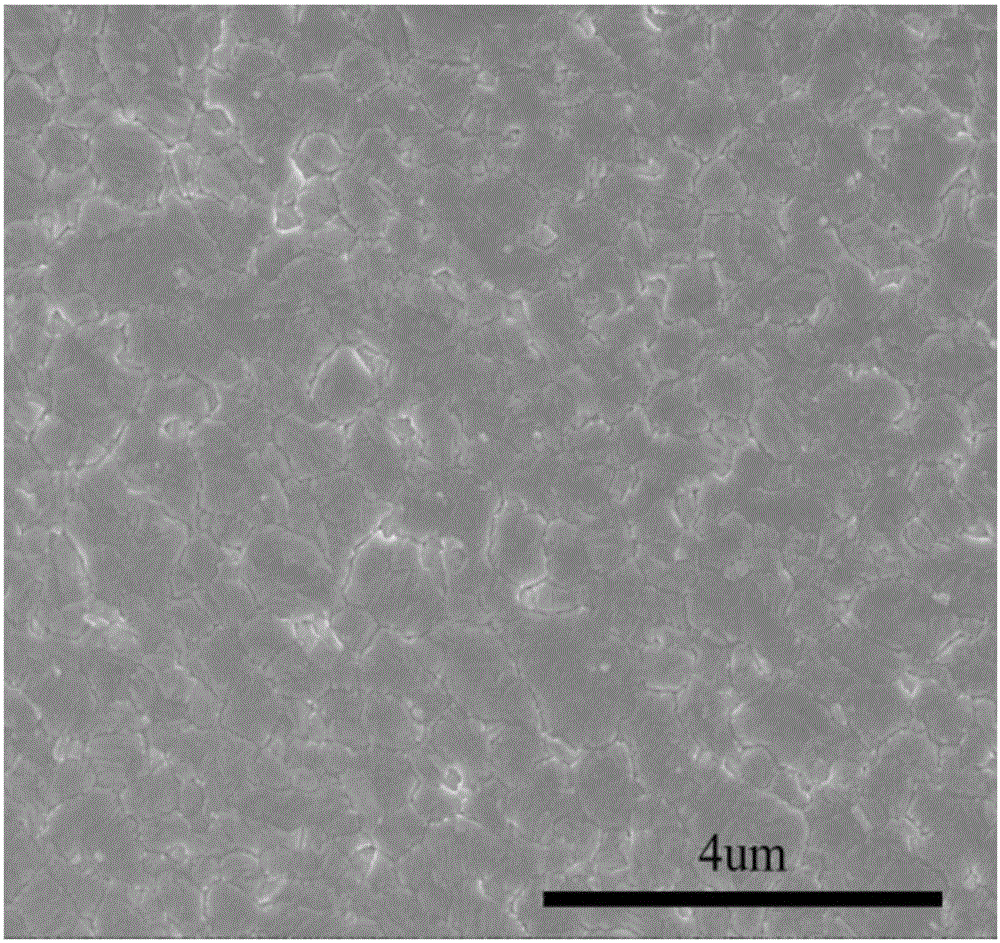

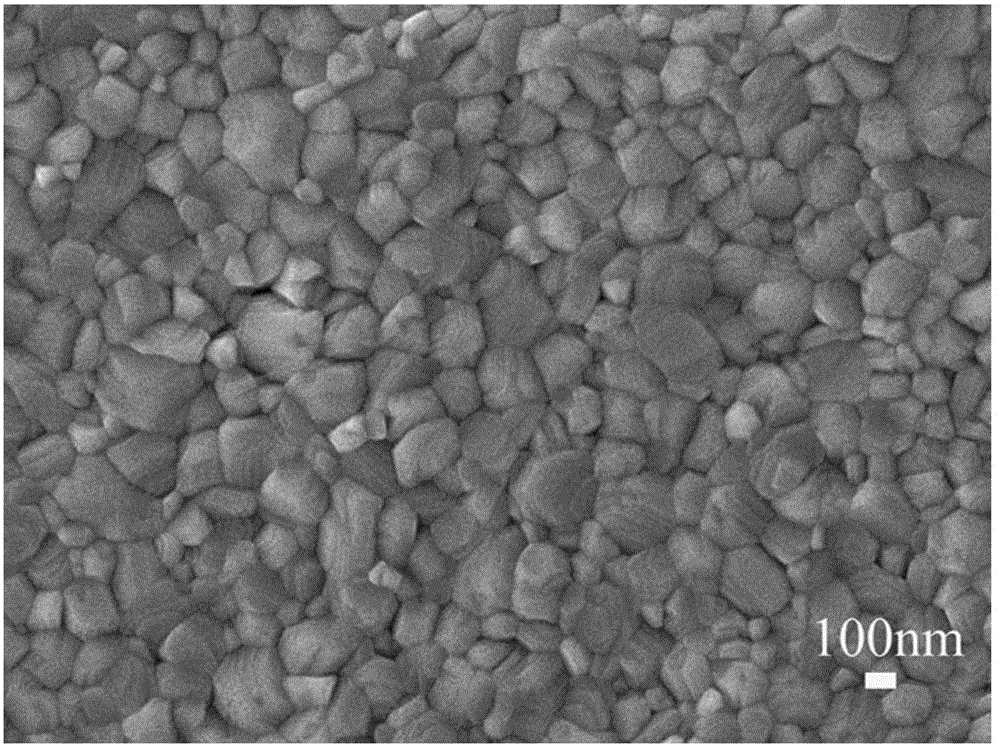

[0041] This embodiment provides a method for preparing a perovskite light-absorbing layer for a perovskite solar cell, which specifically includes the following steps:

[0042] (1) Preheating the substrate, specifically:

[0043] The substrate is composed of a substrate and an adhesion layer attached to the substrate. The substrate is made of glass (with a roughness of 10nm). A conductive layer and a hole transport layer are attached to the glass in sequence. The conductive layer is SnO doped with fluorine. 2 Layer, the hole transport layer is a nickel oxide layer (thickness is 20nm);

[0044] Place the substrate on the heating plate to preheat, the preheating temperature is 220°C, and the preheating time is 30s;

[0045] (2) Form a tight sandwich structure with the substrate as the bottom layer and the dragged film as the top layer, with the perovskite precursor liquid sandwiched between the two, specifically:

[0046] a. Configure perovskite precursor liquid

[0047] Solu...

Embodiment 2

[0069] This embodiment provides a method for preparing a perovskite light-absorbing layer for a perovskite solar cell, which specifically includes the following steps:

[0070] (1) Preheating the substrate, specifically:

[0071] The substrate is composed of a substrate and an adhesion layer attached to the substrate. The substrate is made of glass (with a roughness of 30nm), and a conductive layer and a hole transport layer are attached to the glass in sequence. The conductive layer is SnO doped with fluorine. 2 Layer, the hole transport layer is a titanium oxide layer (thickness is 100nm);

[0072] Place the substrate on the heating plate to preheat, the preheating temperature is 180°C, and the preheating time is 20min;

[0073] (2) Form a tight sandwich structure with the substrate as the bottom layer and the dragged film as the top layer, with the perovskite precursor liquid sandwiched between the two, specifically:

[0074] a. Configure perovskite precursor liquid

[0...

Embodiment 3

[0084] This embodiment provides a method for preparing a perovskite light-absorbing layer for a perovskite solar cell, which specifically includes the following steps:

[0085] (1) Preheating the substrate, specifically:

[0086] The substrate is composed of a substrate and an adhesion layer attached to the substrate. The substrate is made of glass (with a roughness of 50nm), and a conductive layer and a hole transport layer are sequentially attached to the glass. The conductive layer is SnO doped with fluorine. 2 Layer, the hole transport layer is a titanium oxide layer (thickness is 200nm);

[0087] Place the substrate on the heating plate to preheat, the preheating temperature is 180°C, and the preheating time is 20min;

[0088] (2) Form a tight sandwich structure with the substrate as the bottom layer and the dragged film as the top layer, with the perovskite precursor liquid sandwiched between the two, specifically:

[0089] a. Configure perovskite precursor liquid

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com